In 1962, when he was put in charge of Chrysler Corporation, Lynn Townsend famously pushed the company into racing and muscle cars, because his kids had told him Plymouth and Dodge lacked “street cred.”

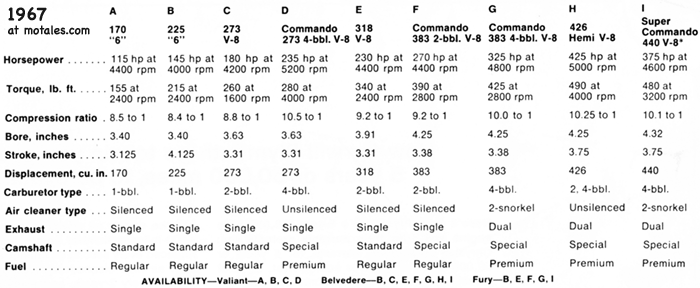

Plymouth and Dodge’s big-block V8 engines, with their innovative tuned intakes (“Cross Ram”), were competitive on the street, but the Chevrolet and Ford teams had more money and more experience and were doing far better in NASCAR. Engineers decided that the best path forward was to go back to the hemispherical heads which had worked so well in the first Chrysler V8s. These early Hemis had, because of their cost, size, and slow production, been repeatedly altered until they became the small-block LA engines; they also had never gone past 392 cubic inches. Could similar heads go onto the company’s newer, bigger engines?

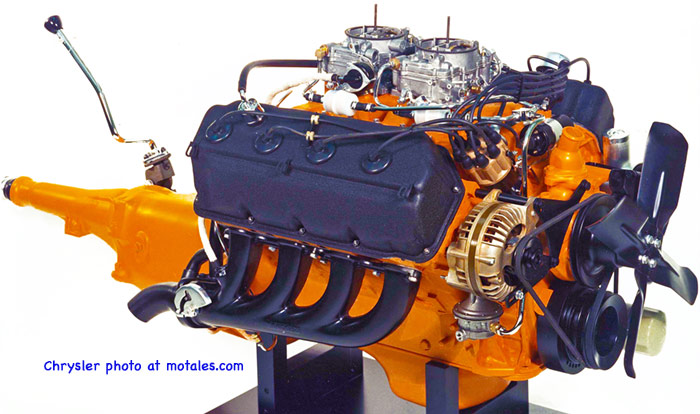

Massive intake manifold was tuned for specific power ranges; this particular 390-horsepower “wedge-head” engine was used in the Chrysler 300J just before the 426 Hemi hit the track.

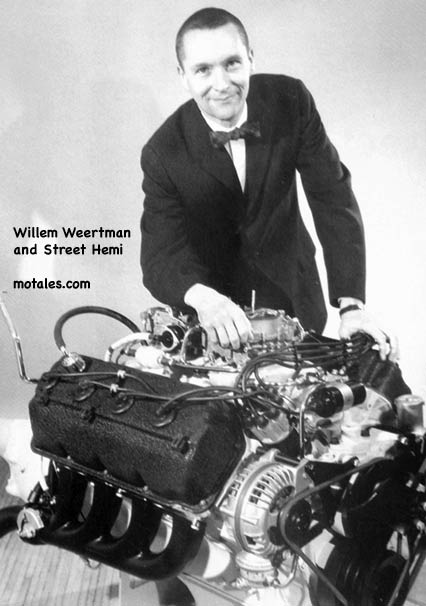

The engine design people tried putting hemispherical heads on top of a big-block “raised B” (RB) engine—the reverse of putting wedge heads onto the first generation Hemis—in a program approved in 1963. Engine chief Willem Weertman recalled:

When the order came we assigned our best designer to it, with Bob Rareya and me looking over his shoulder. By making changes to the block, we were able to do that job with a brand new set of cylinder heads having machined Hemi chambers that just happened to have the same included valve angle as the 1951 Chrysler Hemi—and it worked. [For more, see Allpar’s interview with Willem Weertman]

Tom Hoover, often been called the father of the 426 Hemi, started working at Chrysler in 1955; he was one of the engineers responsible for the incredible Slant Six Hyper-Pak, which helped Valiants at the first and only NASCAR compact car race to place first through seventh. In 2009, he said, “When we got the green light to go ahead and adapt the Hemi head to the big B engine, we realized that one day it would be something revered, that it would be something that everyone would look back on as something very special indeed.”

He also said that he and Don Moore used the Hemi partly because it was the cheapest and most certain way to get ahead; the company had a good deal of expertise in hemispherical head designs from its 1950s engine programs, which were not too far in the past in 1963. He told Mopar Muscle in 1994, “We knew with the power level we could expect, we could provide performance and win races for minimum expenditure. You could continue to hone and evolve the Wedge forward, but the results would be limited.”

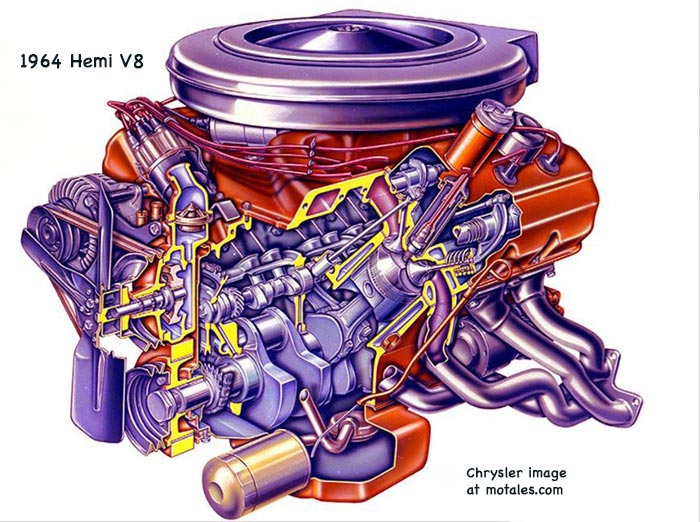

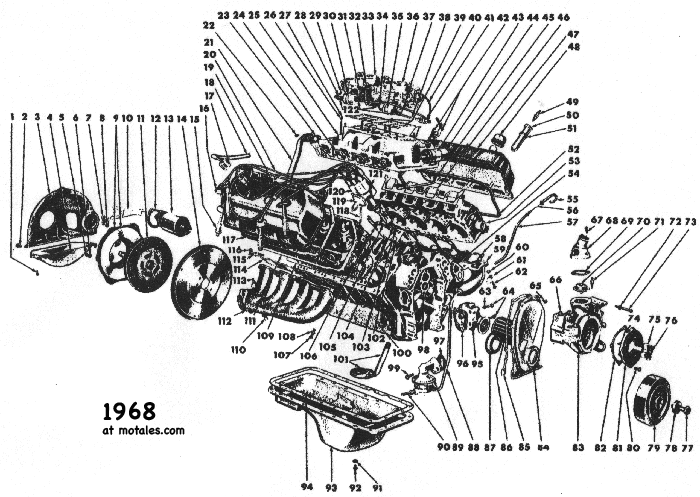

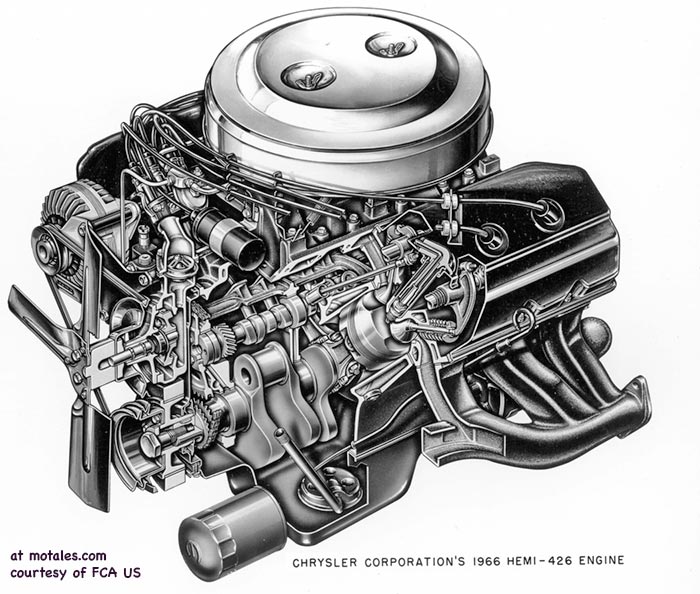

Chrysler used a single cam in the V-8’s valley, with pushrods activating dual rocker arms (hence “Dual Rocker”). Their choice of a single cam, two-valve-per-cylinder design may have been to reduce cost, increase durability, or both—or it may have simply been because that was the configuration they knew best. In any case, the 426 Hemi had much larger valves, with higher lift, than the other Chrysler engines:

| (1970) | 440 | 426 |

|---|---|---|

| Intake diameter | 2.08” | 2.25” |

| Exhaust diameter | 1.74” | 1.94” |

| Lift (exhaust and intake) | 0.450” | 0.490” |

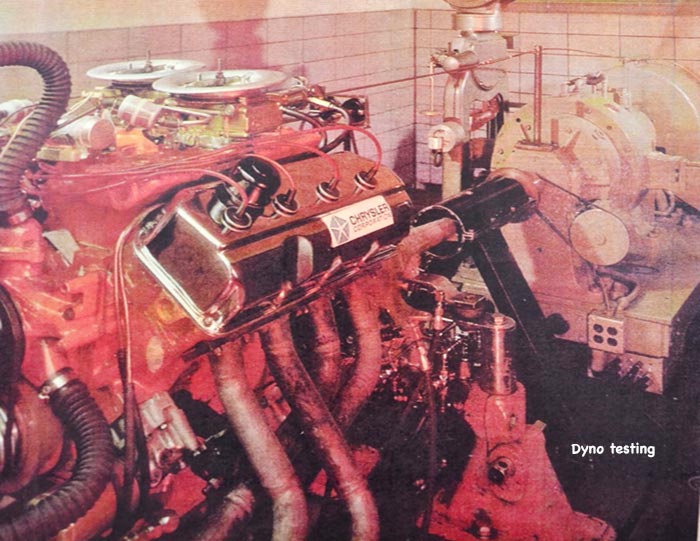

Dyno technician Marc Rozman reported that much of the Hemi development was done in Cell 13, in the middle of the old Highland Park building, because it was a 10,000 rpm dynonometer. “Back in the early 1960s, Bill Weertman and Al Adams came up with the idea of testing engines by matching the demands made on the engine during an actual race.” They computerized the cell to make it easier: first, they recorded the throttle positions and load during an actual race, putting it onto a tape; then they ran the tape in the cell, so the engine would run exactly as it would during a race.

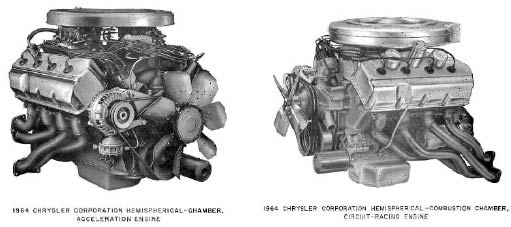

The “acceleration engine” (coded A990) was meant for drag racing, and had a cast magnesium cross-ram intake with twin four-barrel Holley carburetors; it was made in 11:1 and 12.5:1 compression ratios, officially rated at 415 hp and 425 hp. This engine was made by Chrysler Marine. The circuit racing engine was made with a single four-barrel carburetor and two-level intake, with a 12.5:1 compression ratio, and was officially rated at 400 horsepower. This was the NASCAR engine; Chrysler rated it as having 465 pound-feet of torque.

Ed Poplawski wrote added that “Most of the performance engineers were real motorheads so they were easy to work with and were really interested in their jobs. One of the fun guys to work with was Al Nichols. He was the camshaft guru and he had a language all his own that you had to learn so you could communicate with him. He was into everything from carbs to cams and those newfangled things called computers.”

Before making the engine public, Hoover also rented the Fontana drag strip for shakedown testing of all A/FX and Super Stock cars; on the first runs, the Hemi didn’t outperform the old wedge engines. The engineers kept working, ending up with an engine that absolutely dominated American racing.

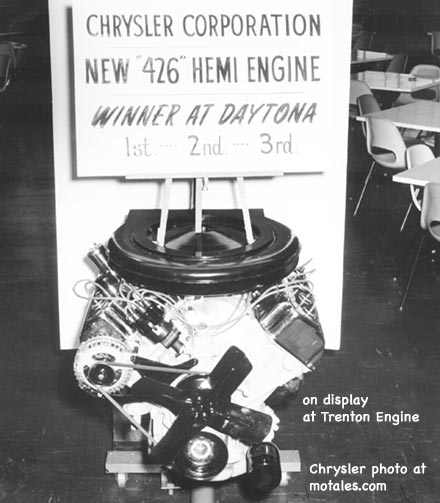

The 426 Hemi’s debut as a racing engine, at the 1964 Daytona 500, was a good omen. Willem Weertman commented, “It was a very rushed program and we were extremely happy when it was successful on race day and we blew the competitors off the track.”

Photo: 1970 Plymouth Superbird

Hemi Plymouths (driven by Richard Petty, Jimmy Pardue, and Paul Goldsmith) took first through third place. A Hemi Dodge driven by Jim Pascal took fifth place. The next Mopars to past the finish line were Junior Johnson at #9, Buck Baker at #12, and Bobby Isaac at #15.

The upset wins surprised just about everyone; but at the end of the season, officials demanded that the company live up to the “stock car” part of the series and produce thousands of “Street Hemis” each year they raced, instead of a few dozen carefully blueprinted and hand-assembled engines just for racing.

Photo: 1969 Dodge Charger Daytona

The Hemi could not be run in 1965 NASCAR races without an accompanying street engine, though it kept going in drag racing—and spurred an attempt at conquering imported sports cars at the Daytona race, with the Plymouth Daytona Continental. The 1964 Hemi had iron heads and dual carburetors on a cross-ram manifold; the next version, the A-990, was made for racing outside of NASCAR. Plymouth sold a 1965 Belvedere with a “Super Commando 426,” as listed in a late 1964 service bulletin; the A-990 engine powering it had aluminum heads and magnesium intake manifolds to cut weight. A number of these might have been made for the engine’s re-introduction to NASCAR racing.

Race Hemis in 1968 ’Cudas and Dodge Darts made the quickest factory race cars to that time; Hemis still dominated the SS/A and SS/AA stock racing classes, decades later, regardless of whose name was on the car.

When NASCAR ruled that Chrysler and Ford could not race with special engines unless they actually sold them to the public, the solution was not as simple as making cars with racing engines. and, basically, work for getting groceries or sitting in traffic as well as racing around a big circle or down a long strip, at a reasonable cost. Compression had to be adjusted for “pump gas,” fuel available at any filling station, rather than racing fuel.

To keep the 426 Hemi alive in NASCAR, Bob Rodger and product planner Robert Cahill had to ask Engineering to make a “street Hemi.” Their engine request letter was dated January 6, 1965, and specified (in their words):

They projected volume at between 5,000 and 7,500 cars starting with the 1966 production year, and noted that the project replaced a previously requested twin-carburetor V8. Less than one full week later, Engineering issued a production letter for the newly coded A102 “Street Hemi.”

Making the engine compatible with the assembly line likely took a good deal of effort. The engineers tilted the combustion chamber to keep the exhaust rocker at a reasonable size, so they could do their normal “body drop” at the Dodge Main plant. (One of the problems of the original, first-generation “Double Rocker” Hemis had been the width of their heads, due to valvegear.) Unlike the Cross-Ram engines, they even had the exhaust manifolds bolted on at the engine plant. The four bolt main bearings of the racing engine stayed on the street version.

Pete Hagenbuch, who later became head of production engine tuning, was one of the people developing the Street Hemi; he wrote that his group’s only goal was keeping performance, with the lowest possible reduction of the redline, with a new camshaft that had hydraulic tappets in mind for the future. He also provided “advice and consultation on matters having to do with valve train.” He remembered that the fillet between stem and underhead was hand spiral polished; and that scuffing of the valve tips, due to the small tip area of the valve stems, was “not uncommon, though never a serious problem.”

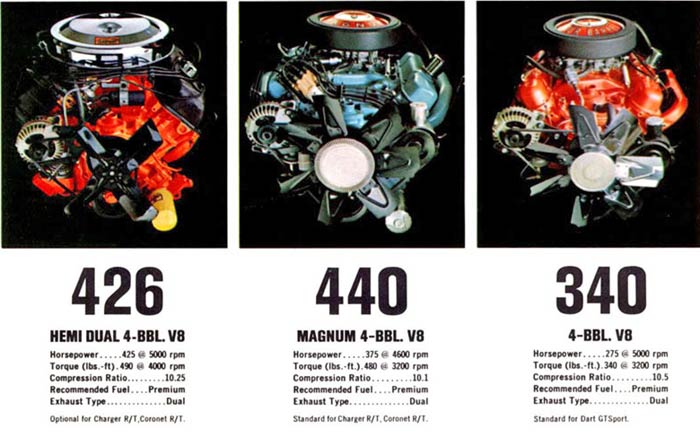

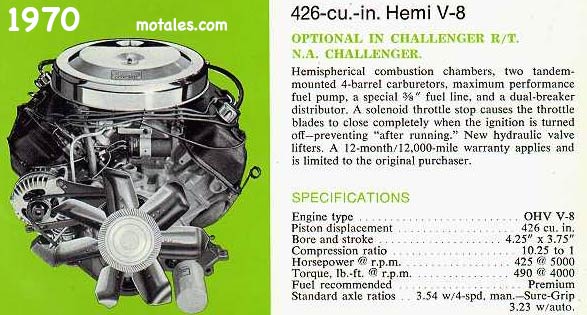

The engine came out as requested; it had lower compression (dropping from 12.5:1 to 10.25:1), with milder valve timing. Bore and stroke were 4.25 and 3.75 inches. They used different manifolds, partly to deal with cold starts and space considerations, and the aluminum heads were replaced by cast iron ones for durability. According to Ed Poplawski, they actually ran a “lab built” engine to 500 horsepower—under controlled laboratory conditions; but there was no need to rate it higher than 425 horsepower, and in some ways it was better to exceed the published figures (for one thing, it may have reduced insurance premiums).

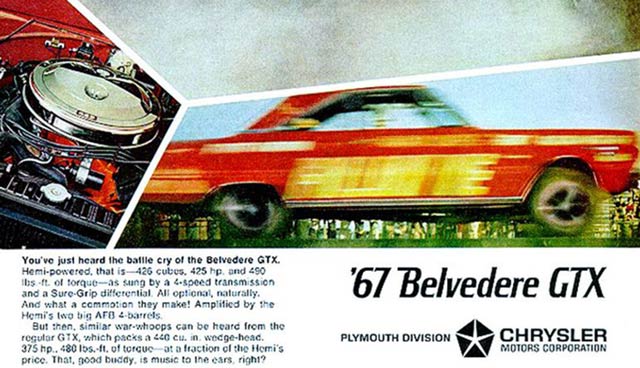

The engine was rated at 425 horsepower (gross) and 490 pound-feet of torque, running on premium fuel. The twin carburetors were Carter AFB models. The valves had solid lifters for the moment, needing regular adjustments, with 292° of duration and 68° of overlap; hydraulic self-adjusting lifters arrived in 1970. Although it looks quite large in the engine bay, and is considerably wider than the wedge 440 V8, it’s smaller than it would have been if they hadn’t kept mass production in mind.

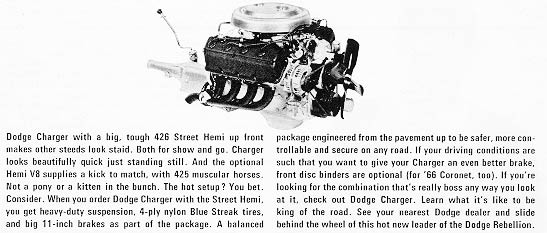

The Street Hemi (internally coded A102 and, starting 1967, A103) was used in the relatively lightweight midsized B bodies, in both Dodge and Plymouth form. The $900-or-higher cost was around a third the price of a whole car with a normal engine, and buyers had to add oil and tune the carburetors far more often; it was a race-bred engine even if it was not a true racing engine.

Meanwhile, Chrysler had boycotted NASCAR for 1965, leading the racing circuit to relent a little, asking that the 426 Hemi be downsized to 405 cubic inches or less. By the end of July, Chrysler had the A117, displacing 404 cubic inches with a shorter stroke (3.558” rather than 3.75”). Richard Petty won four events in rapid succession with this engine.

Once the Street Hemi was ready, though, Chrysler was ready for NASCAR again. They used the modified stroke from the A117 with a wider bore to get back to 426 cubic inches; the shorter stroke was to help the engine stay stable up to around 10,000 rpm. The A148 had a 4.363 inch bore and 3.558 stroke; the intake valve was at 32°, the exhaust valve at 18°. Intake valves had a 2.44” diameter (4 square inches) and exhaust valves had a 2.06 inch diameter. Longer valve springs brought higher lift, and both cast iron and aluminum heads were used; but it was not as relaible as the other engines. It was tried in ProStock but didn’t work well for that purpose, having been designed for NASCAR. The cam was gear drive and the crankshaft was flat; one engineer joked that if your back hurt, the solution was to hang around the dynos when they were testing the flat crank Hemis.

In 1968, the Street Hemi camshaft was modified to add duration (it was now 284° intake and exhaust, 60° overlap); a new cam was used in 1970 with the hydraulic lifters. Otherwise, the engine remained quite similar from 1966 to its end in 1971. The horsepower and torque ratings were unchanged until they moved to net power, and then at least one spec sheet kept the same numbers. The proper 1971 net horsepower—the number you might compare, with some caution, to a 2022 car—was 350. That’s well below a 5.7 Hemi, which is rated at 395 hp in trucks; it’s certainly not in the same class as the 485 horsepower, 392 cubic inch 6.4 Hemi. Gross horsepower was unchanged, at 425.

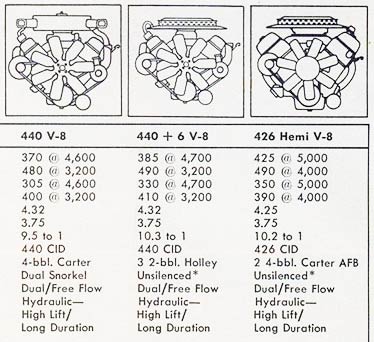

Looking at gross horsepower, the 440 with three two-barrel carburetors was far from the Hemi—385 hp (gross) vs 425. If we switch to net horsepower, the gap was smaller—330 vs 350. (The plain single-carburetor 440 was rated at 305 hp, net; 370 gross.) Torque made a big difference, though: the Hemi was rated at 490 lb-ft, gross, and 390 lb-ft, net. Here, both the four-barrel and “Six-Pack” 440s actually beat the Hemi, with 400 and 410 pound-feet respectively.

Even with the high surcharge for Hemi engines on cars, it likely cost the company more to sell the street engines than they could charge. In addition to the very low production of the engine, which could not be made as quickly or as cheaply as a wedge-head model, Chrysler had to beef up the rest of the car to handle the power; Hemi cars got different suspensions and the best brakes and tires the engineers could specify. Each car took extra care on the line. That may be why the 426 Hemi was one of Chrysler’s very few engines to never be “standard” on a single model, not even the Charger Daytona.

Writing in Allpar, Steve Boelhouwer counted 741 race Hemis in B-bodies in 1964-67, with another 155 in 1968 ’Cudas and Darts. He believed numbers on Street Hemi production were probably inaccurate; but fewer than 11,000 were apparently made, with the first year, 1966, being the most popular with an estimated 3,350 made.

There were definite issues with the Street Hemi; mainly, it required a good deal of care in tuning, and while it was free revving, might not have quite as much torque at low rpm as the high performance 440 wedge engines. In 1968, Car Life tested a 1968 Charger Hemi and Coronet R/T 440 (with a Dart GTS with a 340—a much ligher car—for comparison):

| 426 Hemi | 440 V8 | 340 V8 | |

|---|---|---|---|

| 0-60 mph | 7.6 | 6.6 | 6.3 |

| 0-100 mph | 20.9 | 15.0 | 16.5 |

| Quarter Mile | 15.35 @ 94.6 | 14.69 @ 97.4 | 14.68 @ 96.0 |

The Hemi should have easily trounced the 440 powered car, given its extra 50 horsepower and the fact that the 440 was in a heavy convertible; but the real winner was the mere 340. They explained this as tuning problems with the 426 Hemi. For what it’s worth, they noted that a recent Plymouth Hemi, tested the same year, had run a 13.9 second quarter mile.

Meanwhile, in racing, NASCAR leaders were not happy with the Hemi; and rule changes made it impossible to run the engine effectively. That was not necessarily the end; people tried to save the engine with various methods of cutting its emissions and reducing its price. In the end, they decided, as Willem Weertman wrote, to say that “the Hemi has done its job... we don’t want it to ever get a flavor of being a mild-mannered engine.” It was optional in the 1971 Plymouth ’Cuda, Road Runner, and GTX, equivalent Dodges, and the Charger; but it did not re-appear for any 1972 cars (and was never sold in trucks).

Mopar began manufacturing a new Hemi block in 1993, and started bringing back nearly all the other Hemi parts; then they brought back a new, improved 426 Hemi. These blocks and parts are all for racing only, not the street.

A few heads using twin spark plugs for each cylinder were made in 1970, advertised at least through the 1973 Mopar Performance catalog. Coded P3690038, the dual-plug head was a clever design which didn’t interfere wtih the rocker arms or pushrods. This may have been originally developed as a way to get by emissions issues; dual plugs were a key feature of the 21st-century Hemi V8s, introduced by Willem Weertman, acting as a consultant.

Chrysler historian Curtis Redgap believed a Hemi engine was considered for the Chrysler 300 letter-cars. To be spun off of the A990 racing Hemi, this would be a 440 cubic inch engine with Hemi heads; it had the same 3.75 inch stroke but a 4.32 inch bore, but would be made without the bake-out heat treatment which added cost. Topping the all-out engine would be a triple-carburetor setup and hydraulic cam, both later used on the 440 Six-Pack cars. It was unique among Hemi designs for its two main bearing cap bolts.

Meanwhile, former Design employee and current Chrysler historian Jeff Godshall wrote that the 426 Hemi was part of a plan for the proposed 1966 Chrysler 300M; only five hundred were to be made, but market research showed they wouldn’t even be able to sell that many, so all that is left is a prototype—which does not have a badge.

In 1964, the engineers also designed a dual overhead cam Hemi (a little closer to the 1912 Peugeot), coded A-925, as a response to Ford’s overhead cam 427; when NASCAR disallowed the 427, the project was dropped. A set of parts remain with engine builder (and Mopar Performance guide writer) Larry Shepard. Tom Shaw, in Mopar Muscle, wrote that the DOHC Hemi had cog-belt-driven cams between the heads; it had four valves per cylinder, still activated by pushrods, and could rev to 7,000 rpm. The engine was topped by a magnesium dual-plane intake. While the engine never ran under its own power, the valvegear was checked by running it with an electric motor. Former Ramcharger and writer of We Were The Ramchargers David Rockwell told Mopar Action that the A925 engine program only ever meant to impress Bill France into banning Ford’s overhead-cam 427.

On the other hand, according to technician Ed Poplawski, the Ball-Stud Hemi was meant for street use. The 444 cubic inch Hemi made over 400 horsepower with a Carter Thermoquad carburetor. “We had a few issues with pulling out the studs for the rockers, but that was fixed pretty quickly. There was at least one car with the engine in it, a 1970 Plymouth GTX. ... they were going to try to make it pass emissions.” Then the program was cancelled.

Chrysler Marine produced marine versions of the Hemi for boats. Mayea Boat Works used Keith Black manifolds with them. There were both racing versions and (as Mayea used) pleasure boat versions.

Books by MoTales writer David Zatz

Copyright © 2021-2024 Zatz LLC • Chrysler / Mopar car stories and history.