This page lists factories, what they make, some key products they used to make, and what we expect them to do next.

These are our projections for changes, so far (see the full list for plants that are not expected to change, e.g. Sterling Heights)

| Belvidere | Midsize pickup coming in 2026-27. |

| Brampton | Retooling and modernization throughout 2024. Production of STLA Medium starts in late 2024—Compass apparently first. |

| Detroit | Former Mack making Grand Cherokees. Jefferson Ave will keep making Durango through model-year 2025. |

| Saltillo | Makes Ram pickups, chassis cabs, ProMaster; sole home of Hurricane and Hemi engines. |

| Toluca | Vintage plant deep in Mexico likely to do STLA Medium, losing Compass. |

| Warren | Wagoneer plant. Might add cheaper Dodge version of Wagoneer in calendar-year 2025. Ram Classic ends in 2024. |

| Windsor | Minivan plant adding STLA Large in 2024 with Charger, Wagoneer S, Recon, others. To keep making Pacifica. |

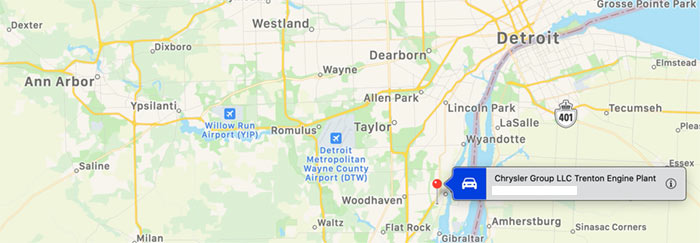

| Trenton Engine | North Plant to be used for logistics and distribution; South Plant makes two forms of Pentastar (original and PUG) as well as heads, cranks, and blocks. New product due for the plant - Hurricane extra line? |

| Dundee | New Peugeot 1.6 (Hurricane 2.0 also rumored to be coming in 2024). |

| Kokomo | 2.0T production and aluminum stamping plants continue. Eight and nine speed transmissions. Extra shift for machining plant. 1.3T engines—using some die-cast machines once devoted to 62TE transmissions—now dropped. Two new battery plants with Samsung SDI. |

GME. Global Medium Engine. 2.0T née “Tornado” and 3.0T “Hurricane” are GME engines, closely related, invariably turbocharged. 2.0T replaces Pentastar, 3.0T may be replacing Hemi V8—two Hurricane versions replace the 5.7 and 6.4, each with more power than the original. GME was developed by a team drawing from Chrysler, Fiat, and Fiat Brazil, and have elements of the old Neon engine, the Pentastar and Hemi, and the old Fiat FIRE engines. GME was likely influenced by primarily-Jeep-and-Alfa use.

EP6 / PureTech. Peugeot 1.6 liter turbo engine to be made at Dundee, solely in hybrid form. Expected to produce ~360-400 hp based on current hybrid versions in Europe. New versions will use Punch Powertrain automated manual transmissions with integrated motors and probably axle motors as well.

Pentastar. 3.2 liter V6 dropped. Twin turbo variety developed from the basic Pentastar design for Maserati Quattroporte and Ghibli, with 404 hp, dropped. 3.6 expected to continue on for one to three years. Still made in three versions, one for PHEV, one Classic, one Upgraded.

Hemi. 5.7 supply already built to meet 2024 production needs. Truck 6.4 to continue.

Hurricane Six: straight-six GME-based 3.0 liter engines with twin turbos and two versions, with power ratings above the 5.7 and 6.4 Hemi. Made in Saltillo, Mexico. Used in Wagoneer, Grand Cherokee; going to trucks and current-generation Durango as well in model-year 2025.

Hurricane Four: might be a renamed GME 2.0, might be some new future engine similar to it.

ZF based transmissions are the 9-speed and 8-speed automatics. 8-speed is entering a second generation with more hybrid capability. Both are made by Chrysler as well as by ZF; Chrysler versions have some differences either for truck capability (e.g. more serious parking pawl) or for manufacturing differences. Chrysler transmissions meet the same standards and specs as ZF ones. ZF nine-speed might be phased out earlier than expected in favor of purchased eight-speeds from Hyundai or Aisin.

Closed and in need of deferred maintenance and upgrades. Belvidere started cranking out cars in 1965; in 1977, they switched over to front drive, making the Omni/Horizon and its derivatives into 1987. Starting in 1988 they went upscale with the Dynasty, New Yorker, Imperial, and Fifth Avenue, which they made until 1993. The first Neons rolled off the line in January 1994, and kept coming until 2005 until switching to Caliber, Patriot, and Compass; and finally Dart. Though Dart and 200 were on the same platform, Dart came from Belvidere and the 200 from Sterling Heights. Dart was replaced by Cherokee in 2017; Cherokee dropped in 2023. To get future Dakota as per union agreement.

This plant in the Bramalea section of Brampton, Ontario, has made the Chrysler 300, Dodge Challenger, and Dodge Charger for those cars’ entire lifespans (not counting the original 300, Challenger, or Charger); it was also sole home of the Dodge Magnum. It’s shifting to STLA Medium in late 2024.

Built as “Bramalea” (the name of the development it’s in), the Brampton plant was put up by AMC just before Chrysler bought the company. It made the Eagle Premier, an AMC-developed version of a Renault which did not live up to expectations, from 1986 to 1992, joined after a time by the Dodge Monaco (a badge engineered car). From 1992 onwards, they made Chrysler’s large cars—the LH series until 2004, then the LX and related models, including the Lancia Thema.

The former spark plug factory that went on to build Vipers is now home to part of Chrysler’s car collection, and is used for meetings and education.

The Mack Avenue complex was a pair of engine plants, right next door to the new Jefferson Avenue assembly plant, which has always made Jeep Grand Cherokees (an older plant nearby no longer exists); the Conner Avenue plant that made Vipers is now a corporate event center and internal museum. Mack was created to make new Jeep Grand Cherokees, and it does so; Jefferson has continued to make the Dodge Durango. If anything else is planned for the new Grand Cherokee platform, it will likely be made there as well.

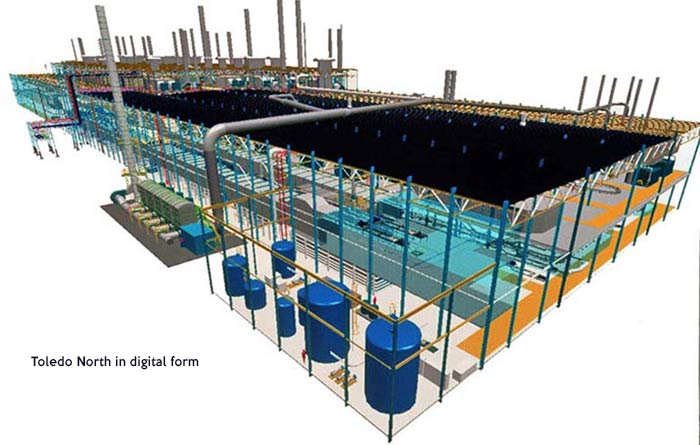

The original Jefferson Avenue plant was built by Chalmers in 1909; Chrysler took it over along with Chalmers, finally closing it in 1991. The Jefferson North plant was put up nearby in 1993. The Mack Avenue plants include one created by Briggs Body (the former Mack I) and another made by Chrysler for engines.There are two plants in Toledo, the South one making Gladiators (originally also making Wranglers), and the North plant making Wranglers. These are relatively new assembly plants, surrounded by a supplier park, and parts are run by other companies.

Toledo North was created to make the Jeep Liberty, designed to be the next generation of the Jeep Cherokee. (When the Cherokee proved to still be popular, they renamed its replacement.) Liberty went into production in 2001; Nitro was added in 2014. They were replaced by production of the new KL Cherokee, and in 2017 by the Jeep Wrangler, with Cherokee moving to Belvidere. Toledo South has always made Wranglers or Gladiators, since being built in 1986 to replace the old Willys plant in Toledo.

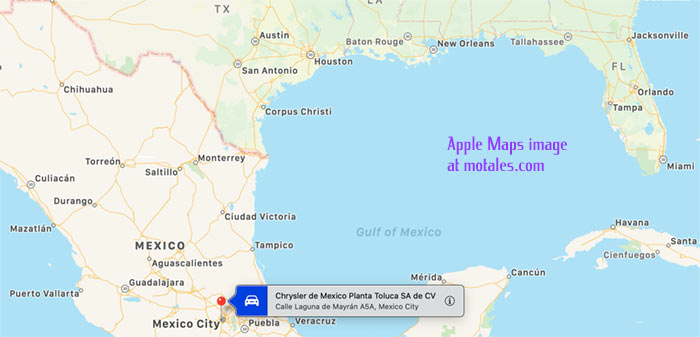

Soon to make the Wagoneer S and Recon. It was built in 1984 to make K-cars; it made offshoots of the K from 1987 to 1994, when it went to Neons and was the only home of two-door Neons. The PT Cruiser displaced Neons in 2001; Journeys joined the line in 2008 and stayed on until their end. Fiat 500 was added in 2011, leaving in 2017. The Toluca plant is the furthest former-Chrysler factory from Detroit—Saltillo is close to the border.

A historic plant which has been expanded numerous times and gutted several times since 1980, Windsor is a modern plant using a flexible pallette system which raises and lowers vehicles as needed. Windsor makes all of Chrysler’s minivans, as it did in 1984, and is also making Dodge Chargers and other STLA Large vehicles in future. The Windsor complex used to have five separate facilities pumping out cars, trucks, and engines, but it’s all come down to one factory. The last of the older facilities, at Pillette Road, made vans. For a full history of Windsor, see our pictorials.

Windsor Pictorials:

Making Mopar Vans in Windsor

Making Mopar Vans in Windsor

Dodge B-van factory photos

Making Cars in Canada: Factory Photos

Making Cars in Canada: Factory Photos

A pictorial with some captions

Making Minivans in Windsor

Making Minivans in Windsor

Chrysler factory photos

Mopar Engine-Based Windsor Factory Photos

Mopar Engine-Based Windsor Factory Photos

Putting engines together in Canada

Off the Line: People Doing Other Things in Chrysler Canada Plants

Off the Line: People Doing Other Things in Chrysler Canada Plants

A pictorial of the labs, factory, and computer control areas

FCA US has three truck plants. Warren is the traditional American facility, and currently makes the luxury Wagoneer and the low-end Ram 1500 Classic (the latter until the 2025s come out). Sterling Heights was converted from making midsized cars and now makes the “DT” body Ram 1500 Quad and Crew Cabs; its capacity is quite high, with a massive new body shop. Finally, the Saltillo complex makes all the heavy duty trucks and chassis cabs, including one unique to Mexico; a separate building produces the Ram ProMaster; and an on-site engine plant makes every Hemi V8 and Hurricane inline six.

Warren Truck has made Dodge or Ram trucks and Dodge B-vans from 1938 to the present, including the Dakota, Mitsubishi Raider, and Ramcharger SUV. The Jeep Wagoneer joined the crew in 2022. Saltillo was originally meant to replace Lago Alberto, a 1930s era factory; it was opened in 1995. Surprisingly, the plant has a zero discharge policy and through filtration provides a surplus of clean drinking water which is used by local residents. Waste is treated on site.

Sterling Stamping used to make K-based cars such as the Lebaron GTS, Shadow, and Daytona; it went on to make midsized “cloud cars” (Cirrus, Stratus, and Breeze) in the 1990s, and continued to make midsized cars until 2017, when the Chrysler 200 was dropped. The factory was heavily rebuilt with a new body and paint shop when the 200 was brought in, and converted over to truck manufacturing in 2017-2018.

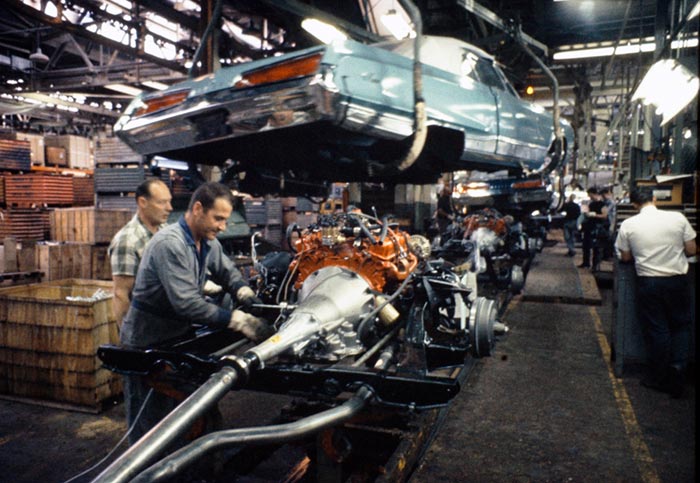

The oldest engine plant is at Trenton Engine, which has an old and new building; they make three varieties of Pentastar V6 and a multitude of parts. Trenton Engine is a decent drive south of Detroit, served by rail and highway, and right on the edge of a nature preserve; it’s also quite close to Grosse Ile.

Moving south, Saltillo, again, makes every Hemi and the Hurricane, as well as two varieties of Pentastar (PUG and PHEV) in a separate facility.

Then there are the new plants: Dundee, built under Daimler, which makes 1.6 liter engines, having lost the 2.4 liter engines and the Pentastar. The new 2.0 liter engines are made at the newest plant, in Kokomo—formerly the Indiana Transmission Plant II. The 1.3 was briefly at Kokomo.

All of Chrysler’s home-built transmissions are made in Indiana, near Kokomo or Tipton; there are two plants near Kokomo which make transmissions, one for nine speed automatics, one for eight-speeds. Kokomo Transmission, which makes eight speeds, also machines nine-speed components. Tipton makes nine-speeds, including a special one for the Pacifica PHEV. A new battery plant in the Kokomo area will make batteries and cells—most likely pure Samsung designs.

Trenton pictorials:

Building Trenton Engine

Building Trenton Engine

to Make Classic V8s and Air Raid Sirens

Building and Running the Slant Six Line at Trenton

Building and Running the Slant Six Line at Trenton

Making the legendary Leaning Tower of Power

Making V8 engines

Making V8 engines

Trenton in pictures

Trenton Engine milestones

Trenton Engine milestones

1964 Hemi to Pentastar

Trenton Engine: Building New V6 Lines in 2000

Trenton Engine: Building New V6 Lines in 2000

A pictorial with explanations and stories

Tales From the Factory: Matching Pistons and Blocks

Tales From the Factory: Matching Pistons and Blocks

How the factory managed precision problems, back in the day

There are four stamping facilities: Warren, Sterling, Toluca, and Saltillo. Each is near an assembly plant. Warren and Sterling Heights are off Van Dyke Avenue, a reasonably short drive from Detroit.

There are also three other support plants—Etobicoke, which makes powertrain components and aluminum die castings; Toledo, which makes steering columns and torque converters; and the beautiful Mt. Elliott Tool & Die (in Detroit), which makes stamping dies and checking and stamping fixtures. Etobicoke, west of Toronto, was built in 1942 and purchased by Chrysler in 1964, and expanded in 1965 and 1998.

Mount Elliott is on the border of the scenic Outer Drive and Mt. Elliott Street; Chrysler has used both names, sometimes calling the facility Outer Drive. The building itself was put up in 1938 by Briggs Body as a stamping plant; it was purchased by Chrysler, with most of Briggs’ assets, in 1956 and used until 1983. At that time, the stamping presses were removed and tool and die manufacturing equipment was brought in from Vernor Tool & Die, which was being closed down. The Mt. Elliott facility also had did pilot plant operations and stamping plant engineering into the 1990s, but these facilities were moved into the Chrysler Technology Center. The plant was idled in 2018 and was due to be closed and sold, but is apparently open once again.

Books by MoTales writer David Zatz

Copyright © 2021-2024 Zatz LLC • Chrysler / Mopar car stories and history.