Fred Zeder, Owen Skelton, and Carl Breer had met in engineering school, where they bonded over a belief in using science and engineering principles to solve problems—at a time when most cars were designed by hunch, creativity, guesswork, and imitation. Many companies lacked serious research labs and testing facilities; for example, when Carl Breer joined his friend Fred Zeder at Studebaker, he found a single, neglected, under-equipped testing lab, which he quickly pressed into use to solve problems with Studebaker engines.

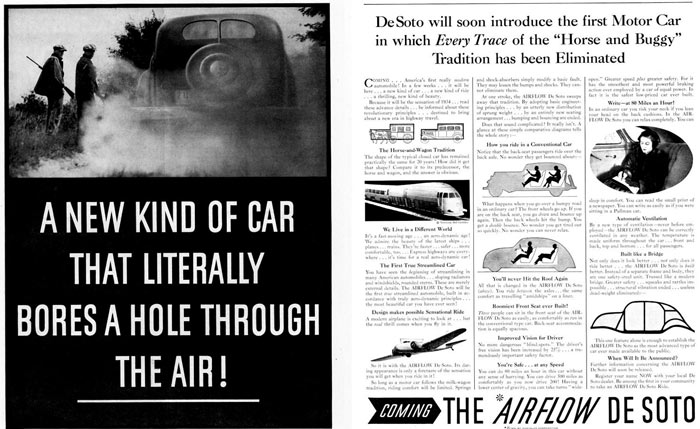

While Zeder, Skelton, and Breer used science to create the Chrysler Six—building numerous single-cylinder test engines, posing and testing theories on what was happening within them, and then building a 68-hp straight-six that took the 1924 Chrysler B-70 to 74 mph—they did not really apply it to the rest of the car, except for components such as the hydraulic brakes, axle, and so forth. The car body remained as it had been, derived from horse-drawn coaches.

Once Maxwell Motors was profitable (and taken over by the otherwise-empty Chrysler Corporation holding company), Zeder, Skelton, and Breer resolved to make a car scientifically. It was an extremely ambitious effort, hampered by the sheer ambition coupled with not thinking about how they would actually build it.

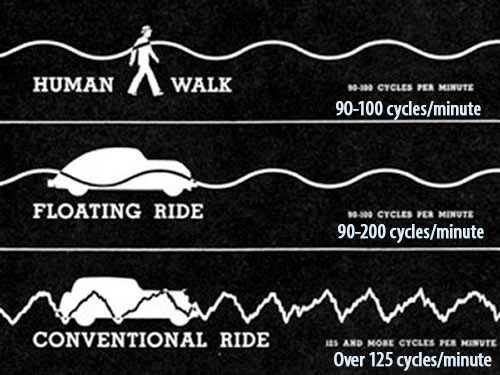

More significant than the aero updates was work on vibration frequencies, center of gravity, and cornering. The team measured the vibrations of numerous cars, including their own, and found that they vibrated at annoying frequencies; European cars of the day were even worse than American cars.

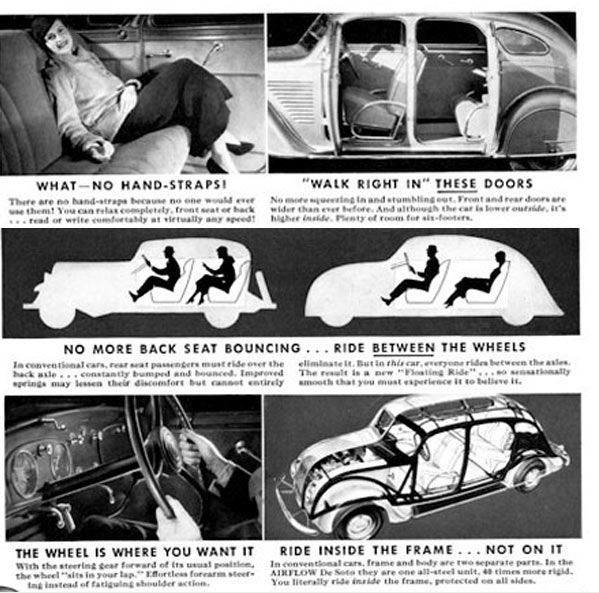

To make the vibration frequencies closer to people at a comfortable walk, they pushed the wheels to the ends of the car, cutting overhang; and stopping passengers from sitting directly over the rear axle, which any bus rider knows is not the best place to be. Sitting between the axles was far more comfortable, in terms of ride. That meant moving the cabin forward, so to speak—which meant moving the engine 20 inches forward, to ride over the front axle.

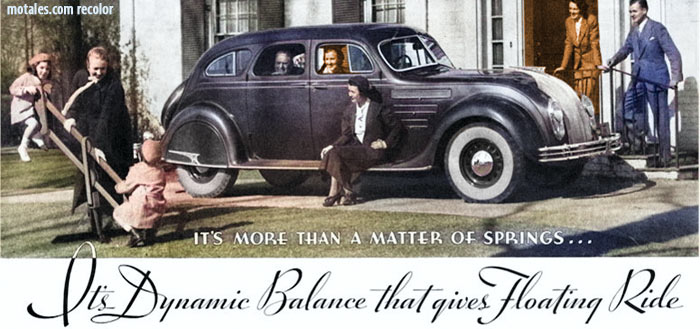

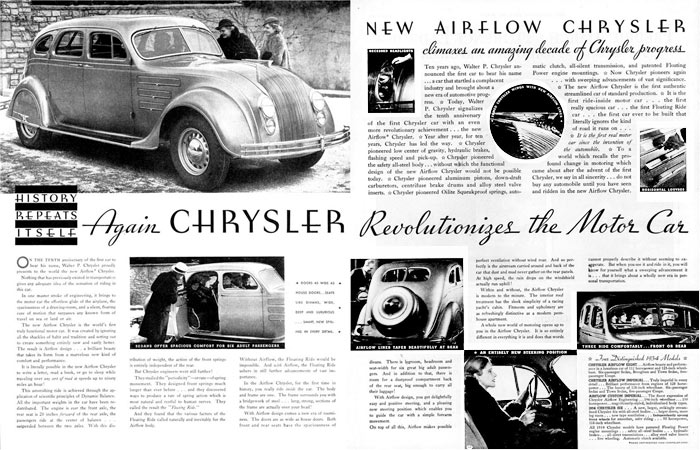

The end result of that was, in marketing-speak, “the first ride-inside motor car... the first really spacious car...the first Floating Ride car...the first car ever to be built that literally ignores the kind of road it runs on... It is the first real motor car since the invention of the automobile.”

As Chrysler’s ad-men wrote in 1934:

The engine is over the front axle, the rear seat is 20 inches forward of the rear axle, the passengers ride at the center of balance, suspended between the two axles... the action of the front springs is entirely independent of the rear. Chrysler engineers... studied the “periodicity” (or rate) of spring movement. They designed front springs much longer than ever before, and they discovered ways to produce a rate of spring action which is most natural and restful to human nerves. They called the result “Floating Ride.”

Under the hyperbole, Carl Breer and his research team did go back to scientific principles, and every one of their changes was based on theory-driven experiment — including the new spring lengths and rates.

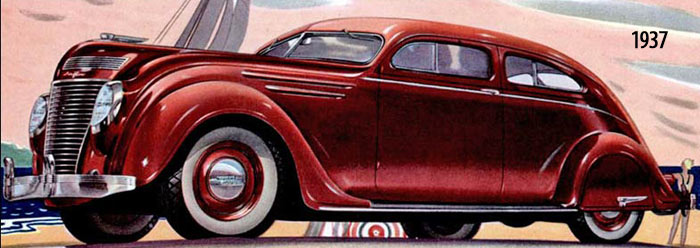

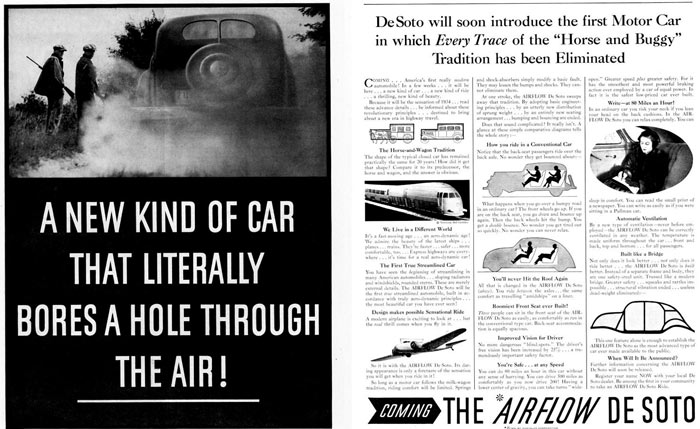

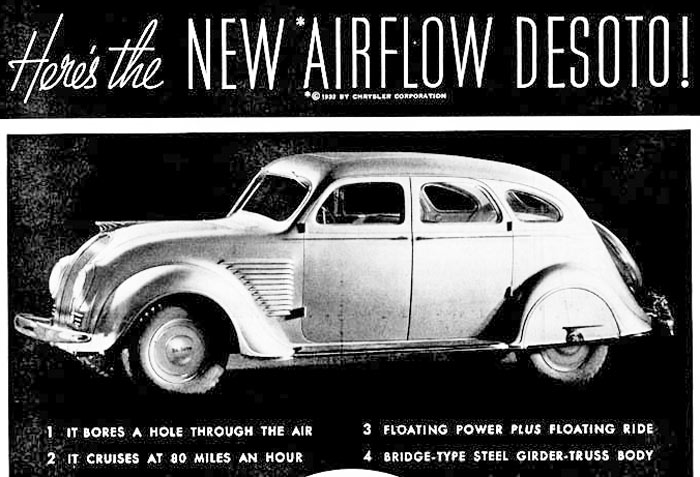

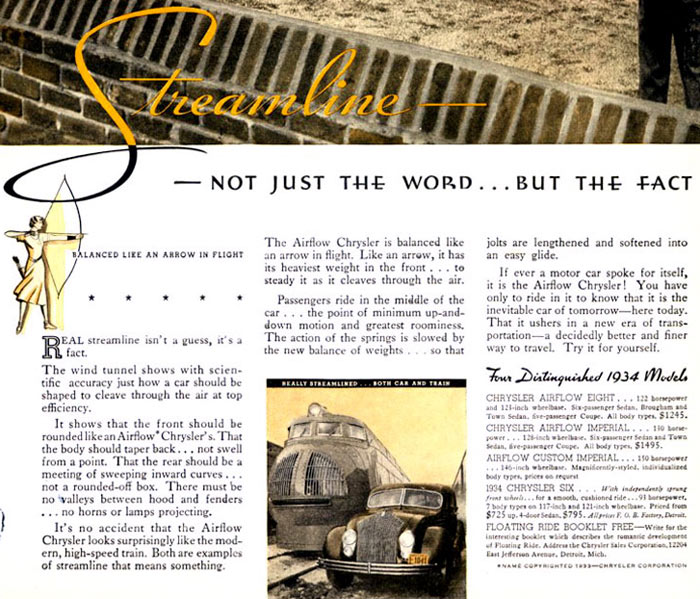

Carl Breer, as head of R&D, observed the company’s cars and decided that their basic shape was not right; aerodynamics were clearly more important, even with the original 1924 Chrysler, given its 74 mph tested top speed (officially promised as 70 mph). Knowing Chrysler lacked knowledge of aerodynamics, he brought in Ohio engineer Bill Earnshaw, an aero man; who brought in airplane makers Wright as well. They started aerodynamic testing, using small models in a wind tunnel, while a larger one was built at the Highland Park headquarters (still for models). Some cars had less drag when put into the wind tunnel backwards, leading one of the team to walk to the window, point, and say, “Look at all those cars going backwards out there.”

As they worked on clay models in the wind tunnel, they realized that regular cars create a vacuum behind them, which drags it back (a lesson unlearned in later years); tapering the end made the car longer, but solved that issue (spoilers were still in the future). The front had curved surfaces to let the air go by more easily.

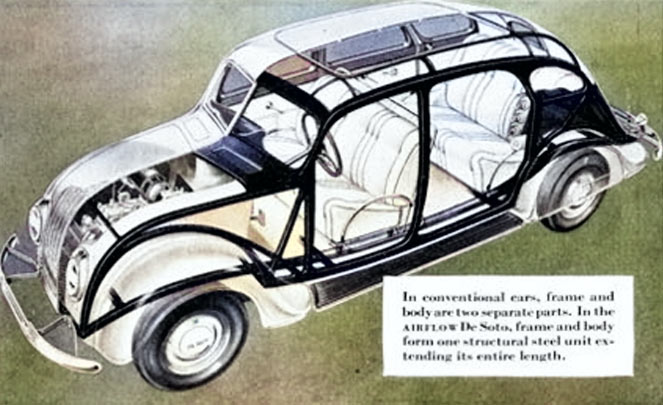

Because the ZSB team discovered that a stiffer body helped both cornering and ride, they decided to make the Airflow body part of its structure. Eschewing the ladder frame of the day, the Airflow series had a sort of cross between an airframe, unit-body, and auto frame. Its frame ran up the fender line, crossed the cowl, and went around the door openings. Body panels were then fitted to the frame, making it much stiffer than the era’s body-on-frame cars.

The boast that Airflow was “the first ride-inside motor car” is explained both by having everyone ride between the axles, and the words, “the body and frame are one. The frame surrounds you with a bridgework of steel,” so that you are indeed riding in the car. It depends on how one defines “the car.”

An internal Chrysler report later noted:

The Airflow car, which was one of the most rigid cars that has ever been built, [had] a light frame to assemble the chassis units. It also had a very long body extending to the front of the car, with the hood sides reinforced to carry the load from the spring ends. ... Some of the disadvantages of the Airflow were the long expensive body; the extra length for shipping bodies; the difficulty in making yearly front end changes, the expensive service cost in front and repair; [and] ... some of the loads were carried locally by the frame before distribution to the body.

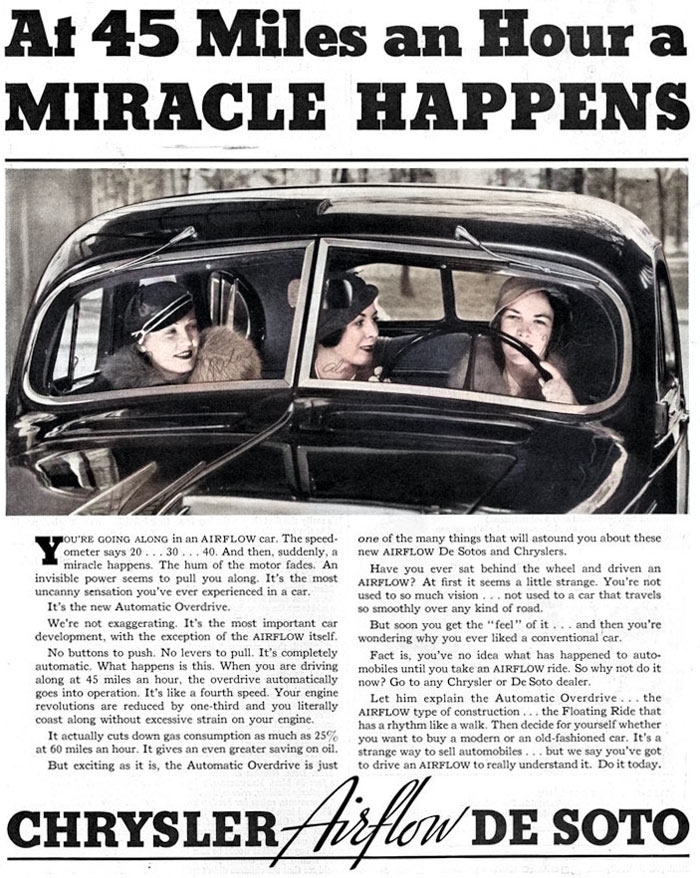

The automatic overdrive system was ahead of its time; at 45 mph, as the ad shows, the Chrysler Airflow could shift into overdrive on its own, allowing the engine to drop in revs, quieting the interior and increasing fuel economy. This is one reason current Airflow owners tend to be confident at modern highway speeds—and why the speedometers were marked up to 120 mph (though that top speed was optimistic).

The Philco radio, installed in the dashboard for $55, was an innovation in itself; with a superheterodyne circuit designed for car use, it could be run with the engine running or the engine off, though without the generator’s power, its tubes would drain the battery before that long. The unit had full-sized speakers, a mini-equalizer with four points, and automatic volume control.

Chrysler had to work with Pittsburgh Plate Glass to create the new first curved safety windshield; they were created by taking sheet glass, still warm, putting it onto a form, and letting it bend into the form on its own. Curved glass was only installed on the luxury Chrysler CW, a nine-passenger sedan which also had the first power partition window. One of the CWs was later loaned to the most popular radio personality of the day, Major Bowes.

The Chrysler and DeSoto Airflow series were both revealed at the 1934 New York auto show, ten years after revealing the original Chrysler B-70 there. Customers were enthusiastic, placing over 20,000 orders—but nearly half of those would be withdrawn in the months between the car’s unveiling and its actual production.

Zeder, Skelton, and Breer had been so excited that they had not really explored how to make it. Between being far longer than usual—so it couldn’t negotiate the turns in the relatively small assembly plants used then—and requiring new techniques for construction, with the new frame/unibody concept, the Airflow needed much more factory preparation than any prior Chrysler. Problem after problem cropped up and had to be resolved. It didn’t fit into existing car carriers, either, so delivery and production were both expensive, raising the car’s price—and it was during the Depression era.

GM and Ford knew they had nothing that could match the Airflow, when they too saw it at the auto show—and if it had been sold immediately, they would have been stuck. Since there would be months before the first cars could be sold, though, they started a vicious rumor campaign about the new Chrysler and DeSoto (and were among the first buyers of one). Mechanics were annoyed by the modern-style hood, hinged near the cowl, which was less convenient than the twin engine covers of the day (one on each side of the engine).

Ford quickly adapted the Airflow’s unique attributes to its own body-on-frame cars, which sold like hotcakes. Chrysler did the same with its Airstream series. The Airflow itself sold in dismally small numbers. DeSoto, which was exclusively selling the Airflow, had a 47% sales drop during 1934, fixed in 1935 when the conventionally styled, lower-priced, body-on-frame Airstream joined it.

Part of the poor sales came from the unconventional look, so they replaced the huge waterfall grilles meant for (but not really giving) high aerodynamic efficiency. That did not help much—the Airflow cost too much to make, and the premium price was simply too much for a Chrysler during the Depression. Packard might have gotten away with it, but Chrysler could not.

Long term, the company had lost market share but also became overcautious—countering its main strength. However, they also realized styling was more important than they had thought, and brought in a designer rather than relying on their own and Briggs Manufacturing’s instincts. Carl Breer, for one, thought the main issue was the long delay before they could build the car, which prevented word of mouth from working against the smear campaign and unconventional styling; and he complained about Briggs Manufacturing’s desire for conventional designs with narrow windshields. Still, he had to admit that using body-on-frame design was much cheaper, and provided for the wide panoply of body styles expected “between the wars”—business coupe, coupe, sedans of different sizes, wagon, and so forth.

Chrysler did not show any more interest in aerodynamics, which would have increased gas mileage and top speed while cutting noise, until the 1969 Dodge Charger 500 and then the Charger Daytona and Plymouth Superbird; but on production cars, aero work wasn’t a priority until after the fuel crisis took hold. Chrysler, like Ford, took the Airflow’s basic design changes, in terms of moving the axles, engine, seats, and enclosed trunk with exterior access, and called it the Airstream, using their body on frame technology. It was cheaper to make, and DeSoto doubled their sales in 1935 with both lines; at Chrysler, the Airflow never took the majority of sales, and after a few years it was quietly dropped.

Auto historian Curtis Redgap argued that the Airflow “was the car that all cars of the future would be based upon. For the first time, passengers rode between the axles instead of on them... The ride was markedly improved, in fact, at the time it was considered just sensational! It also marked a new form of body construction... like a unitized system with a series of interlocking squares that the body panels were fitted to. It was every bit as strong as a unit body, and far stronger than the body on frame cars then built.”

He recalled that his grandfather ordered one; like all the Airflows his dealership ordered, it arrived three months late. His relatively cheap DeSoto (still costing more than the entry level Chrysler) sold at $995; it had the new six-cylinder (251 cid) and electrically controlled overdrive. With 100 horsepower driving just 3300 pounds, with overdrive, it was a fast car for the time, and he truly enjoyed it; he thought others liked the looks even if they said they didn’t. A local doctor got one soon after, and on house calls quickly outraced many local police officers trying to pursue with their V8 Ford patrol cars. The police chief eventually got him MD plates so the police would know he was on call.

In one case, as the doctor was rushing to an emergency out of town, he passed by a state officer in a confiscated Packard straight-eight sedan; he said he was running near 80 mph at the time, and pressed the pedal for more. The two cars were roughly even right to the hospital.

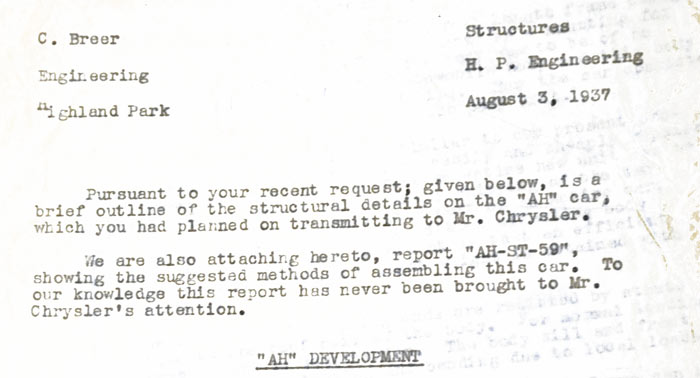

Carl Breer, for one, was still interested in making lighter cars and exploring new frame designs. He instigated Project AH with his R&D area, putting H.A. Hicks in charge, with the goal of exploring the production of a light, efficient car with high rigidity and high performance. The cost of shipping was to be considered, but not the cost production; because the Airflow was unusually long, it had been quite expensive to get to the dealers. This was followed by a later project, coded AN.

Hicks acknowledged that the Airflow was “one of the most rigid cars that has ever been built.” However, because it had a light frame and long body, with reinforced hoods, it was “expensive to build and ship.” It would also be expensive to change the appearance every year, as was already required by fashion; and to repair and service the engine. To get that rigidity without the drawbacks, he proposed using a stub frame for assembly—as Chrysler’s B and C body cars would do. Breer and Hicks agreed that the car could not be longer than usual, this time; and it would “carry the entire load amidships.” The front end would be assembled separately from the rest of the body.

By making the new car’s body in much the same way as body-on-frame cars, they could repair the front end cheaply after a crash, even providing an entire new front end unit. Annual model changes could be made to the front end unit, without affecting the main part of the car.

For rigidity, loads from the spring ends would be “resisted by struts connecting to the roof rail of the body. For normal loading these members are in compression. The body sill and front frame members are in tension and bending due to local loads.” Yet, the frame assembly weighed only 27 pounds. The dash and instrument panel were also designed to resist lateral loads, helping to make the body more rigid. Side-to-side bracing in the rear served a similar function.

Hick added, “[For the AN project], it is possible to greatly simplify the AH construction in detail... [with] many structural details and economies in construction similar to our present production body design.” The AH project weighed 2,348 pounds, quite light compared to the Airflow—2,400 pounds with a heater and upgrades to the structure. It was made with lead solder and handmade parts, and was probably around 48 pounds heavier than a production car would be as a result. The team put over 30,000 miles on it, and Hicks reported on high enthusiasm from “the average engineering department employee” driving it, as well as “eager curiosity” from other motorists.

Hicks concluded that “the future is bright for this type of construction but ... this future will not arrive until keen competition in weight, structural efficiency, manufacturing and operating costs force it into the market.” Due to changes in how it would be made, it “must be carefully considered from this angle by men with constructive imagination and a will to accomplish a worthwhile result.” Hicks had already prepared a preliminary report from the Plymouth factory people.

If the Airflow had been a bit more successful, or if Breer had pushed a bit harder or Briggs Manufacturing had pushed a little less, the new car could have gone onto the market, and quite possibly revolutionized small cars in America—perhaps even giving Plymouth a much better entry into Europe, making Chrysler more of a global concern and better able to survive the GM-Ford rivaly after World War II.