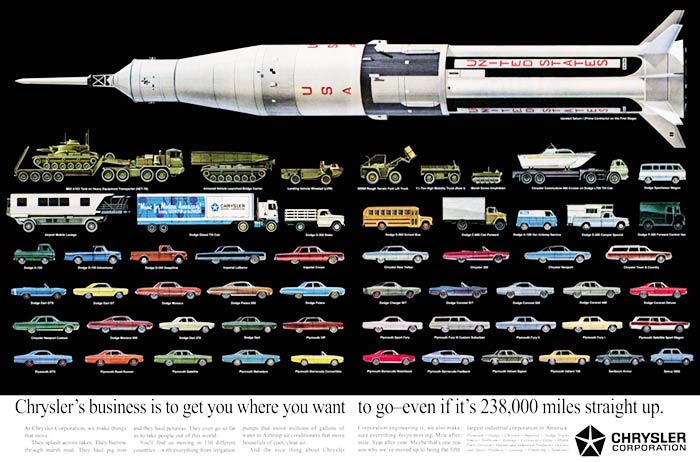

Few today remember that Chrysler was the lead contractor for the Moon rockets—and a big reason why the Apollo missions went quite well. The company also designed and built the telemetry, later applying to their own tanks.

During World War II, Chrysler enthusiastically dived in, working for virtually no profit, cutting their prices repeatedly as they built efficiency, and turning all their attention to military needs. Chrysler earned a reputation for honesty and innovation in government circles, though they were setting themselves up for post-war problems.

As the war ended, the United States brought over a hundred engineers from the German V-2 rocket program, including enthusiastic Nazi Werner Von Braun, to Huntsville, Alabama to be the nucleus of a United States rocketry program. At about the same time, Chrysler continued its work on military radar and atomic bomb circuitry by developing the electronics for new missiles.

Chrysler’s wartime president, K.T. Keller, left his position to take charge of the Army’s guided missile program in 1950. He was a strong leader, quickly centralizing Army and Navy work at the Redstone Arsenal and taking other steps to boost efficiency.

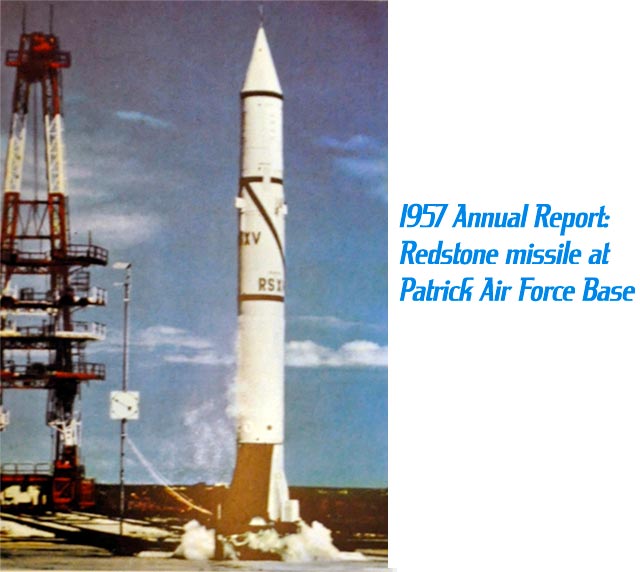

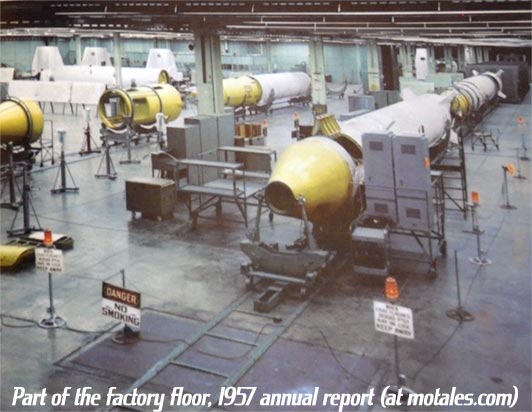

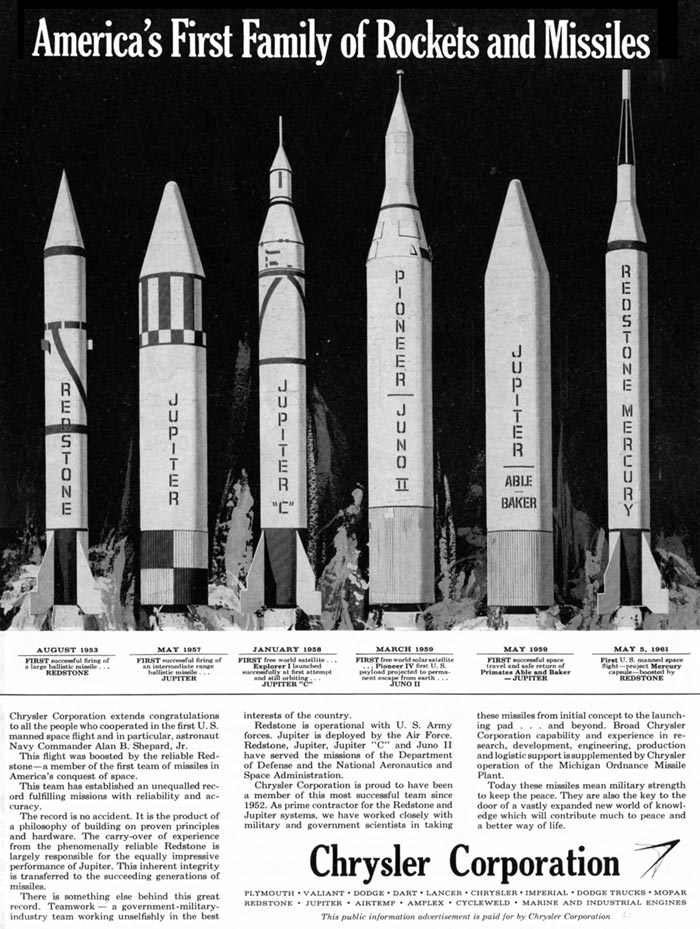

For rather complicated reasons, Chrysler was appointed prime contractor for the Redstone missiles; in their 1954 annual report, the company reported the gain of a “multi-million dollar contract to perform research and development on a secret Army Ordnance guided missile.” The company had spent over $2.5 million on the Navy’s 2-million-square-foot Warren, Michigan factory to build jet engines in a deal which had fallen through; now they pressed it into service to build over a hundred Redstone missiles, initially under the leadership of future turbine-car chief George Huebner. Subcontractors included Reynolds Aluminum (fuselage) and Rocketdyne (engines). The Redstones, which included the Juno-I, Jupiter-A, and Jupiter-C, were used for testing, launching satellites, and carrying nuclear warheads; they were also used for the first two (unmanned) Mercury flights. The Redstones, which were built into 1961, increased Chrysler’s reputation for quality in aerospace, leading to further contracts.

Chrysler Defense 1956 sales fell a bit from 1955’s $195 million, which was 6.2% of the company’s total revenue, to $165 million, or 5.6% of revenue; part of that may have been the end of tank sales from the Michoud plant, closed in 1954. In any case, the company’s role as prime contractor of the Redstone-Jupiter Ballistic Missile programs expanded during 1956; and the government had found no fault when reviewing the 1953 bills. Defense sales fell to $125 million in 1957 before rocketing up to to $325 million in 1958, accounting for 15% of the company’s revenue. Chrysler was producing both Redstone and Jupiter rockets, along with another $72 million worth of M48A2 tanks. Given the company’s 1957 car debacle, which brought sales plummeting downwards in 1958—work stoppages at plants did not help—the military revenue came just in time.

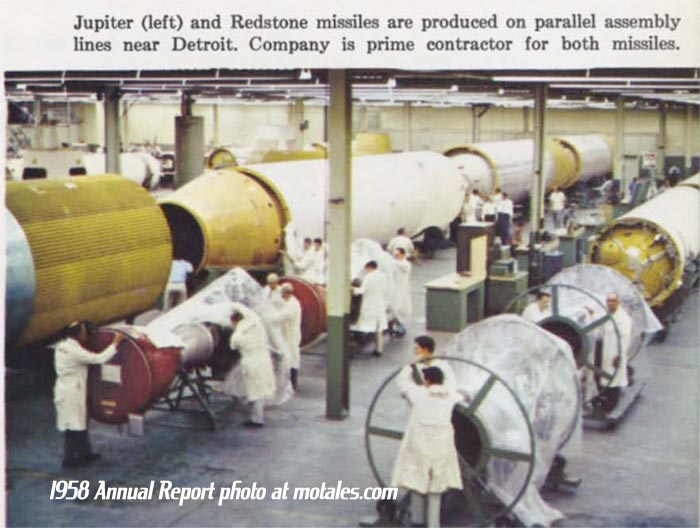

Durnig 1958, T.F. Morrow was put in charge of the defense and aerospace business. The growing missile business was reflected in two new groupings within Chrysler, the Missile Division and an Advanced Projects Organization (the latter for technical parts of “new weapons and space system projects.”) Chrysler, again, was the prime contractor for Redstone medium-range and Jupiter intermediate-range ballistic missiles, made in the Navy plant (operated by Chrysler) in Warren, Michigan. The Redstone was the first ballistic missile to be launched by soldiers in a simulation, and was deployed by NATO forces in Europe.

Reportedly, the United States chose to let the Soviet Union launch a satellite first, so the Soviets could not object to photo reconnaissance satellites. The timing supports that idea: a Jupiter rocket, with a Redstone first stage, launched a 31.5 pound weight into space in 1956, well before the Soviets launched their Sputnik satellite (1957); they could have just as easily put a light satellite into orbit. Two more rockets quickly followed, one launching a 300-pound object (much heavier than the 188-pound Sputnik) hundreds of miles above the Earth. Finally, a third Chrysler-built Jupiter rocket (with a Redstone first stage) delivered America’s first satellite, “Explorer,” in early 1958—part of $52 million in new contracts, signed late in 1957, for more Jupiter and Redstone missiles as well as a Redstone first-stage booster for the Juno II moon probe then scheduled for 1959.

At the same time, Chrysler was making M-48 A-2 medium tanks at Newark, Delaware, next to the auto plant; and setting up work to control the missiles with computers and other equipment, through the Airtemp Division. There was a tantalizing Transportation Corps project for an air-borne vehicle as well.

In 1959, the US intended to reach the Moon, but there was no rocket engine capable of the even a tenth of the thrust they needed. Chrysler conducted a review and suggested using the F-1 Rocketdyne engines, which had already generated 1.5 million pounds of thrust—far, far more than any Redstone. That only took them so far, when many more millions of pounds of thrust were needed. Perhaps, Chrysler Engineering suggested, they could use groups of rocket engines?

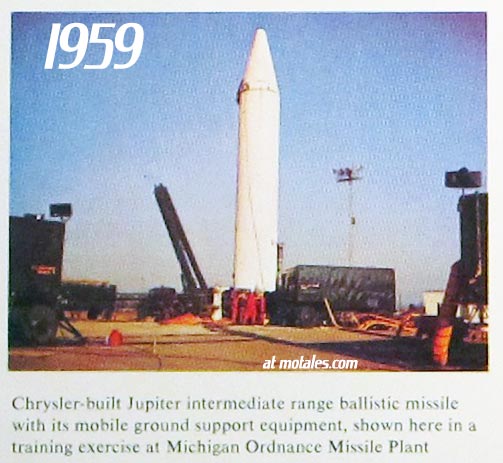

Chrysler rockets had been through 41 consecutive successful firings by the end of 1959; their Jupiter rockets had so far amassed a perfect record of 100% successful launches. Given this, the company was awarded contracts for more Redstone missile boosters, this time for manned Mercury flights—the ones that put the first American astronauts into space (booster #46 did this). Chrysler also gained a contract for modified Jupiter missiles for the Nike-Zeus anti-missile program. Defense sales for this year, 1959, were $286 million—11% of total sales. Even with this, due to problems in the car arena, Chrysler lost $5.4 million over the year.

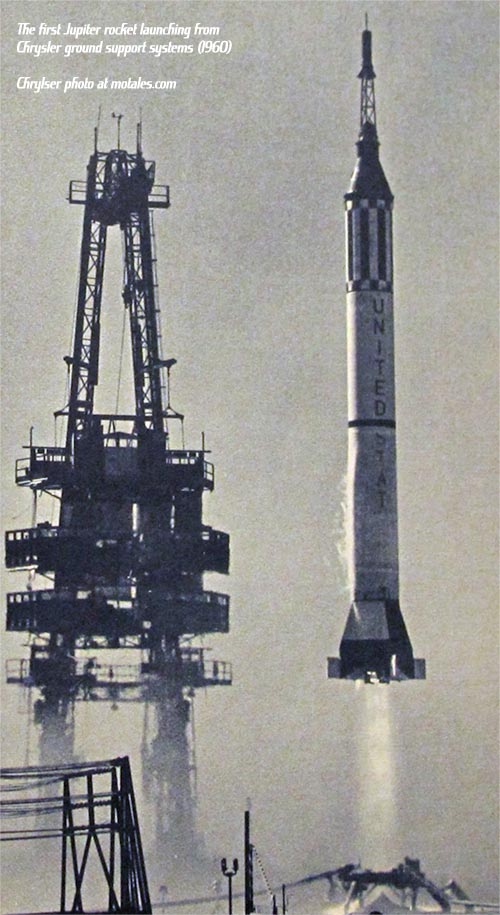

In 1960, Chrysler maintained its 100% launch reliability status for Redstone and Jupiter missiles; and in October, a Jupiter launched from Cape Canaveral (later Cape Kennedy) used Chrysler’s own tactical ground support equipment. The company was busily working on R&D for space boosters, surface-to-surface missile systems, space and re-entry, and ballistic aiming and alignment systems. Chrysler also won a contract for the Twist Autocollimator which would aim the Minuteman mobile intercontinental ballistic missiles. By the end of 1961, the Redstone missile had a 95% reliability record, while all Jupiters had launched successfully; its launch vehicles were used in four Mercury flights, including those of Alan Shepard and Virgil Grissom.

When John F. Kennedy took office in 1961, he was stunned by the $33 billion cost of the Apollo program formally launched the year before; the minimum wage was still only one dollar per hour, to give that number some context. Still, the public was completely behind a Moon mission, especially as the Russians had the first satellite and then the first human in orbit (Yuri Gagarin). Kennedy took the contest seriously: he put Vice President Lyndon B. Johnson in charge of NASA, to act as his personal bulldog and tear red tape to shreds. Johnson excelled in that role, until Kennedy’s unexpected death put Johnson into the White House.

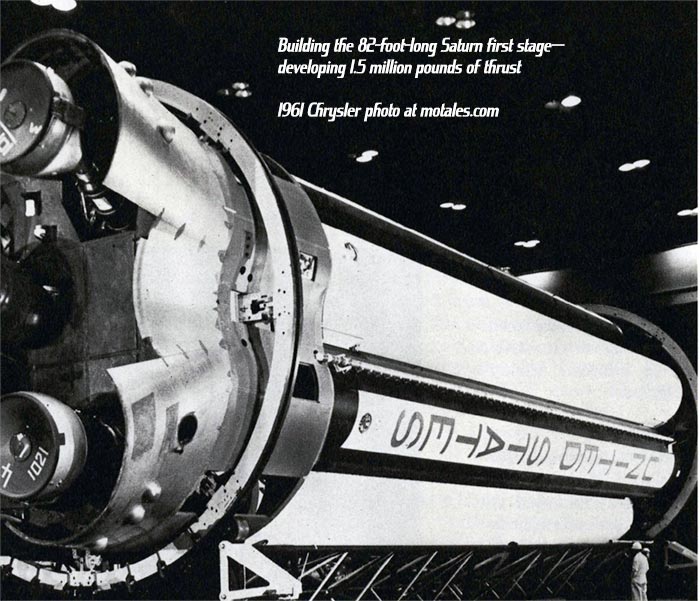

In 1961, Chrysler signed a contract with NASA to “engineer, build, check-out, static test and launch twenty S-1 Saturn boosters” at an expected price of $200 million—reportedly far lower than NASA had expected. This brought the creation of a new Space Division, adding to the Missile Division, headquartered at the Michoud plant. They were also working on classified research for a number of government contracts.

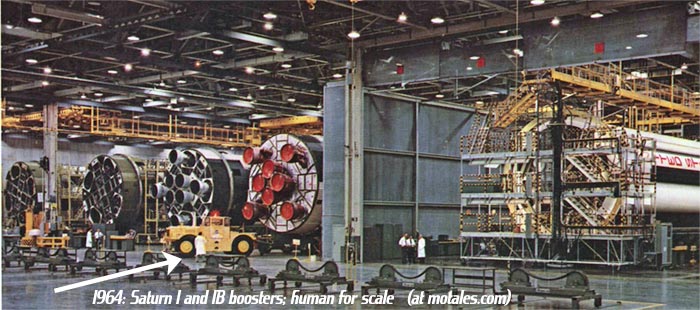

Chrysler engineers had considered multi-engine rockets; the first test of that idea was a set of ten Saturn Is, each of which had clusters of eight H-1 engines; Chrysler design and built the cluster couplings (but not the engines). All ten performed flawlessly, so they made nine Saturn 1B rockets, with considerable power boosts from the same engine series. At this point, Chrysler shifted its role to prime contractor. They would need help to make the entire rockets. The creation of the National Aeronautics and Space Administration (NASA), headquartered in Huntsville, was an administrative change which did not appear to affect Chrysler’s work.

Warren was far too small for the new rockets, so Chrysler persuaded NASA to take over a plant in Michoud, Louisiana. Originally created to make Liberty ships, it had been abandoned during the war when the Army Corps of Engineers couldn’t dig a canal through the swamps to the factory gates. Chrysler had placed a tank assembly line there from 1951 to 1954.

Chrysler started to set up the Saturn V production area as other engineering teams tested two alternative ideas—creating a brand new booster and modifying the Saturn (they chose the latter option); Boeing joined them after some time. Chrysler built the first stage Saturn IB booster, while Douglas made the second stage; telemetry equipment was engineered and built largely by Chrysler’s Huntsville facilities. The capsule was made by Rockwell. The Chrysler “C-5” booster (called Saturn starting in 1963) was the single largest rocket booster ever built, including Soviet 30-engine designs. Chrysler coordinated efforts by Boeing, Douglas, IBM, Huntsville Missile, and North American Aviation as well as building the first, five-engine stage itself. The boosters were designed for redundancy, but were not overbuilt, to cut costs, engineering time, and building time. (Even now, incidentally, Chrysler considered itself almost entirely an automobile company, and the aerospace work barely registered in the annual reports.)

James Webb took over NASA on February 14, 1961. Realizing the cautious process of testing rockets one piece at a time would result in a Moon landing too far in the future, he stopped the testing of the rockets one small step at a time, and started “all together” testing. This strategy was, fortunately, successful.

In its 1962 annual report, Chrysler noted that start of production of 21 Saturn S-1 and S-1B boosters; the contract had now been set at $222.6 million, and was formally signed in July 1962. The first booster was due to arrive at Cape Canaveral in 1964; in fact, it was finished in December 1963 (though it reached its destination in 1964), and would be launched in 1965, carrying a two-ton meteroid detection satellite. The report also noted “research and development programs for tactical missile systems, advanced intercontinental ballistic missiles and reentry vehicles for the Air Force, a Navy sea launch missile program, and electro-optical systems.”

Defense and aerospace together—including tanks and such, as well as rocketry—were responsible for fairly hefty amounts of Chrysler’s revenue, ranging from 5% to 10% of the company’s total sales in these years. Oddly, the annual reports did not call it out on the balance sheets, mixing it in with general sales, along with Amplex, Airtemp, and such. The company spent more space on SIMCA than Defense/Aerospace in most annual reports.

| Revenue (millions) |

% of Total | |

|---|---|---|

| 1962 | $252 | 10% |

| 1963 | $263 | 8% |

| 1964 | $214 | 5% |

| 1965 | $245 | 5% |

| 1966 | $195 | 3.5% |

| 1967 | $212 | 3.4% |

| 1968 | $269 | 3.6% |

| 1969 | $162 | 2.3% |

| 1970 | $140 | 2% |

Defense and space sales in 1967 were $212 million, or 3.4% of total company sales, compared with $195 million in 1966.

1965 saw the Saturn rockets in use at last; in May and June placing in orbit the “largest instrumented satellites ever launched” (both meteoroid detection satellites), while the more powerful Saturn S-1B entered the testing phase. The S-1B was designated as the booster for the Apollo lunar program—set to start in 1966. The launch crew wore Chrysler shirts. The first S-1B launch, part of a two-stage vehicle, was slated for early 1966 to test launch and re-entry. Chrysler again provided the launch team.

During 1966, the first three Saturn S-1B launches were successful; over five years, NASA had tested 13 Saturn rockets and 13 had been succesful. The third S-1B launch tested the S-1VB second stage, made by Boeing in the same facility with Chrysler as prime contractor; the S-1VB used liquid oxygen and liquid hydrogen. As a side note, while Redstone production had ended by this time, the company was brought in to modify existing missiles for a research program in Australia. Chrysler was responsible for refurbishing the boosters, upgrading their guidance and control systems, and building payload systems; Chrysler personnel also operated ground support equipment and provided launch help in Woomera, Australia, where they were launched. During 1967, they were able to recover a reentry vehicle in good condition, the first time this had been done.

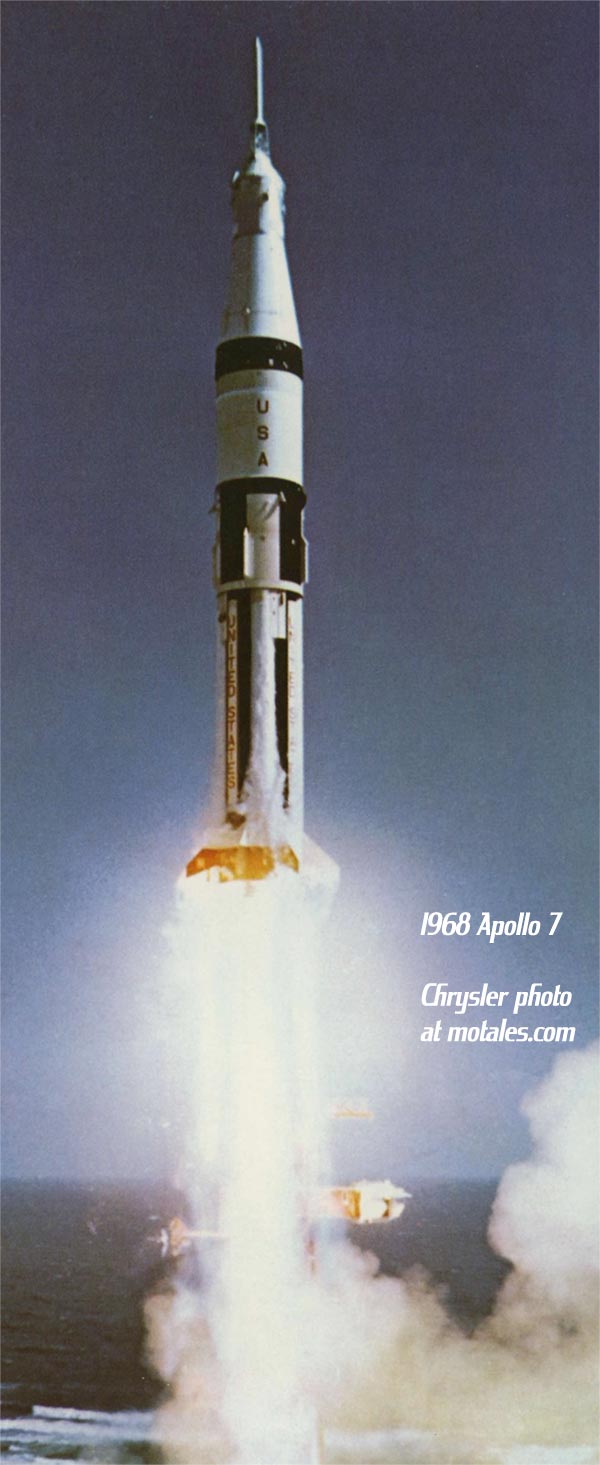

The uprated Saturn rocket was flight tested for the first time in 1967, leaving the ground; the blast was so strong that Walter Cronkite, reporting from four miles away, found his room shaking and ceiling tiles falling with the shock. The next rocket carried the first unmanned Apollo lunar module into Earth orbit in January 1968; in October, a Saturn 1B launch vehicle carried Walter Schirra, Donn Eisele, and Walter Cunningham on their historic eleven day flight. It was the most powerful launch vehicle used up to that time in a manned flight—and the 15th straight Saturn success. NASA awarded Chrysler a year-long contract to study future launch vehicle design. The computerized checkout systems which supported 1B were adapted for making cars, too.

Eighteen Saturn V rockets were made. The first was just used to check the fit and function; the second to test vibration proofing; and the third for static test firing. Apollo 4 was the first to leave the ground, on November 9, 1967. Apollo 6 was another test flight; the first crewed flight was Apollo 8, on December 21, 1968.

The first lunar landing was from Apollo 11 in mid-1969, followed by Apollo 12; both landed successfully on the Moon before returning the astronauts to Earth. During 1969, with the various Saturn 1Bs already made, Chrysler maintained the rockets and carried out research for NASA; they worked on electrostatic devices for gravity-free environments. Personnel worked on modifying the facilities for the next launches, and on carrying over lessons and systems to automotive production. Apollo 13 launched in 1970, famously had problems unrelated to Chrysler’s work, and had to return to Earth; Apollo 14, 15, 16, and 17 all landed astronauts safely on the Moon from 1970 to 1972.

As aerospace work lagged for Chrysler, despite the aggressive Apollo launch schedule, the Space Division used its expertise to create a new vehicle exhaust analyzer and a computerized mail sorting system, among other things; they started equipping Chrysler with advanced test and research equipment, and in 1971 began making car radios (operating on 20% of the power of most auto radios, using the type of circuitry they had developed for missiles).

In 1970, NASA awarded Chrysler a contract to explore a space shuttle, then dubbed SERV (single stage, earth orbital reusable vehicle)—Nixon’s proposed replacement for the Apollo missions. Chrysler proposed a ring-type booster, which was seen as impractical and not chosen (though some today believe it was, and is, practical). Chrysler also started to convert one of the Saturn gantries for Skylab; the Chrysler-built S-1B was the launch vehicle to move astronaut teams to Skylab (this would be the Apollo 18 launch, renamed to Skylab 1). The space station replaced the third stage, which was put onto display at the Johnson Space Center.

Apollo 19 and 20 were cancelled; there was talk of using them to put up an international space station and then a backup Skylab, but it never happened. President Nixon saw no advantage to continuing the Moon visits. Each mission cost around $186 million, $110 million of which was the Saturn space vehicle. Chrysler had performed exceedingly well, but after this point, found little aerospace work; and many of the engineers refreshed Chrysler’s car business with their expertise and ingenuity.

No mention of Chrysler is made anywhere on the Saturn V Wikipedia page as of 3/13/2023—or on, say, the Apollo 12 page. Chrysler’s work on the space program has, by now, mostly been erased from public memory.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky