The creators of the 1924 Chrysler met and bonded around their belief in using science to develop cars. This not only made them invaluable at troubleshooting, but made the Chrysler unique for its time, and later yielded the first truly modern car, the Airflow. They applied Newton’s law of centers of percussion, for example, to design both the Airflow and their railroad cars, finding the best locations for axles, springs, and mounting points that way.

Chrysler railroad cars began with an unsatisfactory trip on a train. Carl Breer, head of Chrysler research, wrote that they could make the most comfortable car in the world, but its driver would take a beating on the train to work, with “jolting and uncontrolled bouncing.” Breer quickly realized that trains were “as far as possible from nature’s basic law of the center of percussion.”

Breer set up Robert Janeway with a new railroad lab to see if he could make trains faster and safer by changing their weight distribution. Breer also thought that train speed could be dramatically increased by cushioning railroad cars from bumpy rails and controlling their side-to-side drawbar motions. Walter Chrysler brought in the New York Central Railroad, in the person of engineer Paul Kieffer; Bill Vandersly and Perce Best also joined the effort. As they had with the Airflow, they started with miniatures in the lab, and altered weight distribution to counter lateral “whip” forces, as Breer had directed, and through observation and theory; they created “self-banking” cars which could withstand strong lateral movements. Pennsylvania Railroad President Martin W. Clement reportedly said, “I have seen more engineering in this laboratory than I have in my entire life in the railroad business” (according to Breer).

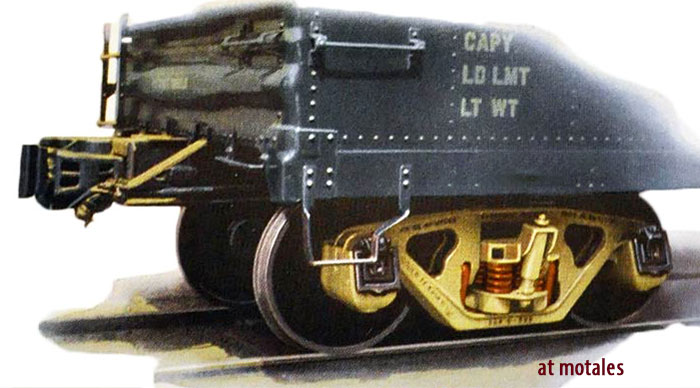

Rail cars consisted of a box on an undercarriage which held the wheels, suspension, and support structure, called a “truck.” When the railroad gave Janeway’s team some existing, worn trucks to examine, they found that the trucks were not working as they were meant to; nobody else had checked to see if the mechanisms were working as designed. Areas meant to absorb shocks were not working because of unlubricated metal-to-metal contact, so the entire assembly transmitted forces right through to the car. The team tried lubricating the surfaces, but dust quickly destroyed that effort. The next step was using ball bearing thrust plates between the bolster and frame, then thrust links with rubber ends; both ideas were patented and licensed to railroad car makers. Next, they tried lowering diaphragm and buffer pressure between cars, and adding lubricated rubbing surfaces and lubricated, highly-finished bolster pressure plates; and lowering their leaf-spring rates, while adding spring covers to keep their lubrication free from dirt.

A set of train cars, named the Mercury series, were built with these innovations, along with, on later cars, thrust links on the trucks; the New York Central Railroad found these cars could run faster than older designs, and yet were far more comfortable. The next step was lightweight steel side member trucks, which not only had a far better ride, but ran that way for over 100,000 miles. With these successes (and their resulting patent royalties) and the mighty Pennsylvania railroad joining the effort, Chrysler’s lab acquired its own full-sized train and test tracks.

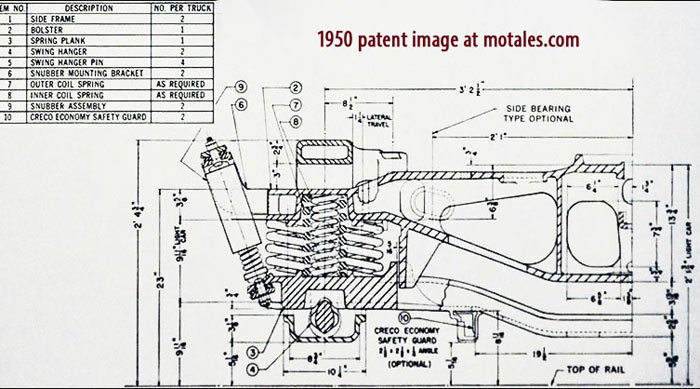

Janeway kept moving on. The next patent, filed in 1942, covered a truck frame suspended by swing links to cut back on unsprung weight, insulating passengers or cargo from vibration. He then tried splitting the truck into two components, with wheels and axles split from the side frames. Now, he mounted the car's support beams on springs, so they could move freely up and down; side-to-side movement was restrained by compression and tensile forces. This setup ended rubbing between the parts, with their “attendant joltings and progressive wear.”

A new step forward came in 1945, when Breer and Janeway jointly filed for a “torsionally neutralized” railroad truck—it removed mass from between the truck and the car body, to prevent oscillation and other effects. By this time, they had a full sized test train, using vertical and lateral accelerometers, and observed truck action through windows in the train floor. By 1945, the main concern for the nation was supplying the war effort, so Chrysler worked on freight cars. Given the national shortage of freight cars, which were needed to transport parts for planes, tanks, and so forth, Chrysler decided to stop licensing their patents one at a time and make their own railroad freight cars.

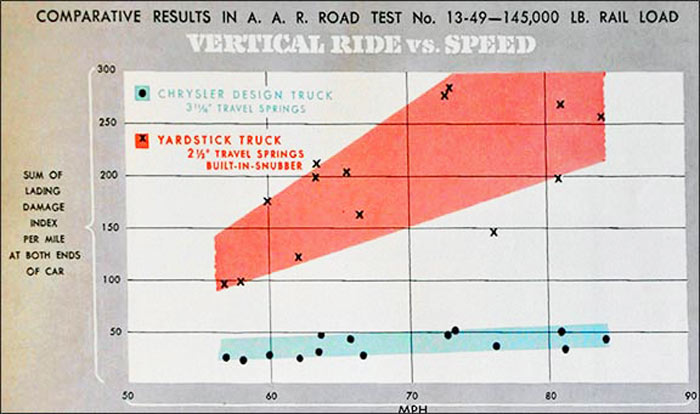

One goal was to maximize the amount of freight any train could carry by allowing much faster speeds; cargo speed was limited at the time by the tendency of the rail car to jostle its cargo, causing damage. Chrysler’s 1950 brochure bragged that “freight cars equipped with Chrysler Design truck can carry any load, up to full capacity, at passenger train speeds, with full protection from rail originated shocks.” They backed up their claims by saying, “Several years of hard-accelerated service on some of the largest railroads have demonstrated its endurance and dependability, reduced wear, and lower maintenance costs.” Indeed, tests of their freight cars showed that, after 44,763 road miles, the average total wear of all the load-carrying surfaces was only 0.039 inches. They achieved this in several ways:

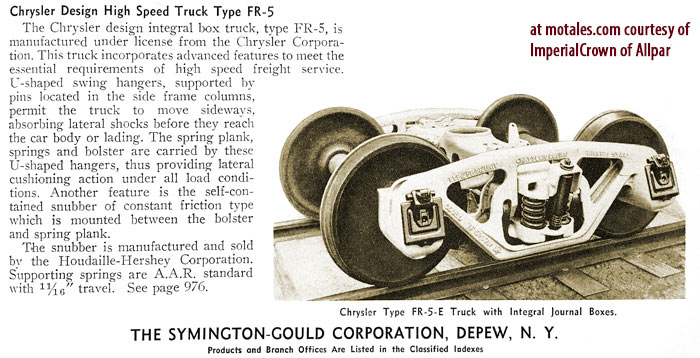

The design was meant to be practical for large railroads. Wheel changes could be doen with “a jack, wood blocks, and a crowbar.” Their trucks interchanged with older models and used standard American Association of Railroads coil springs, journal boxes, and brake rigging. That made it easier to upgrade existing cars, and far easier to do maintenance and repairs without buying new equipment. The trucks themselves were subcontracted to Symington-Gould of Depew, New York, while the friction snubber was made by Houdaille-Hershey of Buffalo, New York. While they weren’t as popular as they should have been, they did stay in production for some time; the FR-5 model was made at least through 1957.

Chrysler Design Trucks were used for ATSF Express cars, Fruit Growers’ Express refrigerator cars, B&M mail cars, B&O Express freight cars, C&O gondola cars, Pennsylvania Railroad Merchandise Service box cars, New York Central Pacemaker cars, and UP stock cars.

General American-Evans used the Chrysler setup for their “Damage Free” box cars, coded GAEX, which had high weight capacity as well. These were made in two phases, starting in 1950 and 1955, and leased out for 25-year periods; they looked like normal train cars but with shock absorbers. They weighed in at 7,700 pounds with single wear wheels and brake rigging, but no car; all were painted dark green. As they were returned from leases, they were rebuilt and repainted; each railroad’s logo and marks were painted on at the factory. The Pennsylvania Railroad still leased 138 GAEX cars in 1968; their dark green color made them stand out against the Pennsylvania’s dark red uniform. In 1974, General American rebuilt 65 cars as GAEX 74000-74064 and sold them to railroads. What happened to the rest of the cars is a mystery at this time.

General American-Evans reported a few testimonials:

These were clearly a superior design—created by science. Chrysler’s press release explained the details:

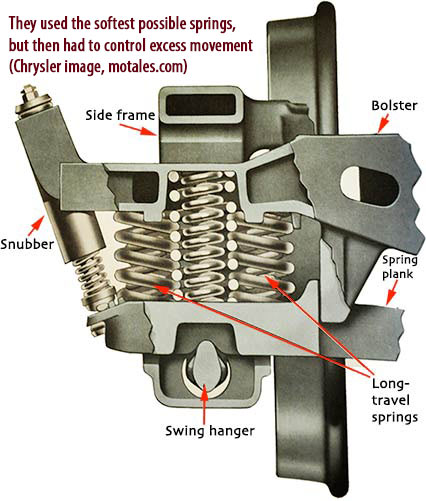

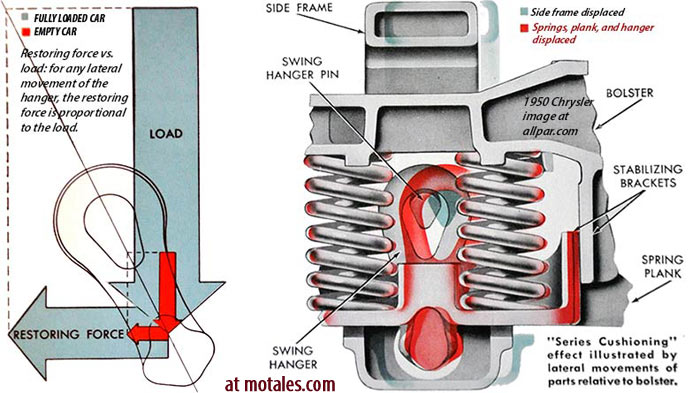

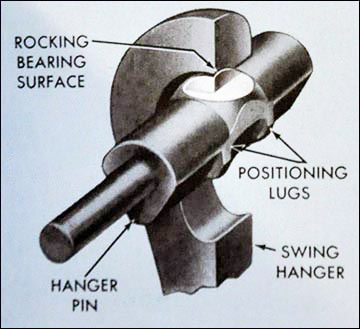

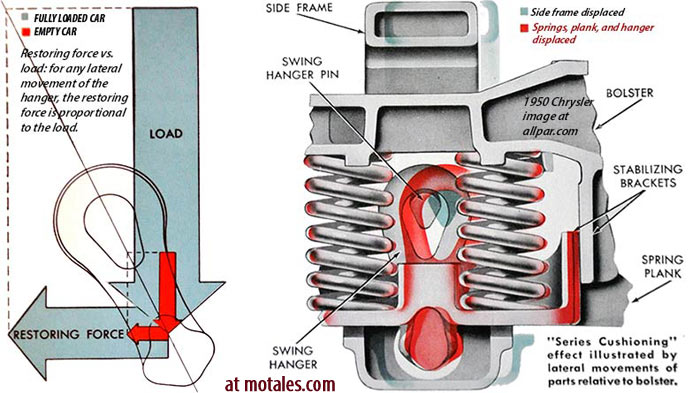

The freight car body is suspended on U-shaped swing hangers, which act like pendulums. The swinging action of the hangers allows the trucks to move sideways relative to the car body, absorbing the lateral shocks from the rails before they can reach the car body and the lading. The smooth, shock-absorbing effectiveness of the swing hangers is independent of load -- therefore, the fully loaded freight car is protected to the same extent as a lightly loaded freight car.

The stability of the side frames is assured regardless of the lateral displacement. Any unsquaring tendency of the side frames is resisted by the torsional stiffness of the horizontal portions of the U-shaped swing hangers supporting the spring plank. Because there is no free-play in the hanger mountings or between the plank and hangers, the side frames are effectively held in square alignment.

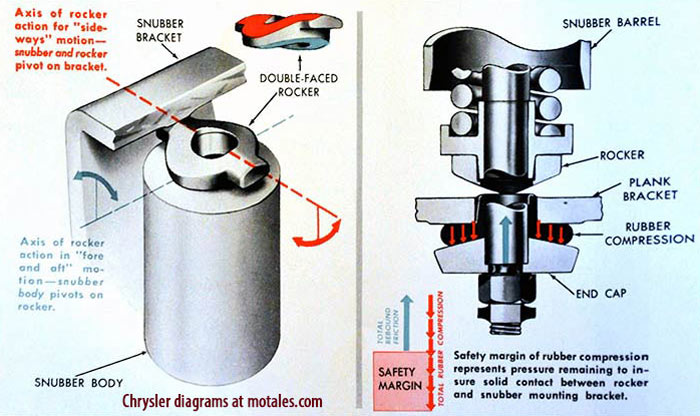

The cushioning of vertical impacts is obtained by low rate, long travel, standard Association of American Railroads (AAR) coil spring groups. Self-contained, constant-friction snubbers of the expanding shoe type control the coil spring action. The snubbers are mounted on the outside top: The wide spacing, which is the maximum allowed within AAR clearance limitations, imposes the greatest possible frictional resistance to car body roll.

The snubber [shock absorber] connections consist of forged rockers preloaded by rubber compression blocks. The assembled rubber compression blocks and rocker connections maintain solid contact in overcoming snubber friction. This construction was developed to avoid uncontrolled vertical vibrations of the car body. At the same time, the connections allow the necessary universal-joint action to accommodate the relative movements between the bolsters and the cast steel spring plank.

Chrysler barely mentioned this business in their annual reports, and their association with railroads is almost a secret today.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos