Chrysler started working on the “Phoenix Engine” in 2004; it was intended to replace not just a panoply of Chrysler engines, but the Mercedes V6 as well. “JDM” wrote that Mercedes wanted a 90° V6 and in the end they could only agree on a common piston. The Phoenix name was taken from a fighter plane, along with Hemi names such as Eagle and the prior 4.7 V8 (Corsair).

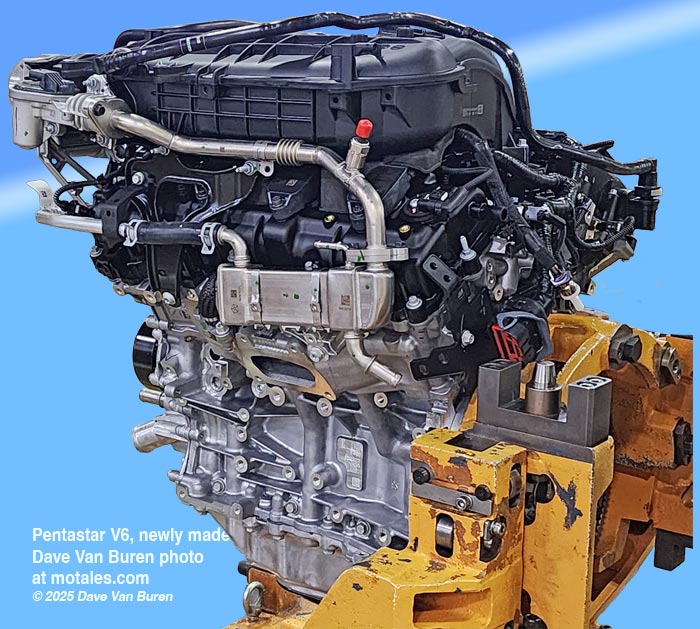

As the “Phoenix engine” was in its final phases, Cerberus executives decided to use Nissan engines instead. A well-timed leak to Allpar may have kept it alive; but in any case, Cerberus showed off the newly renamed Pentastar engine (Phoenix had been trademarked already) in 2009 and put it into production. Three plants pumped out the engines (Saltillo, Dundee, and Trenton) for quite some time; in 2024, two plants (Saltillo and Trenton) are still making them by the thousands.

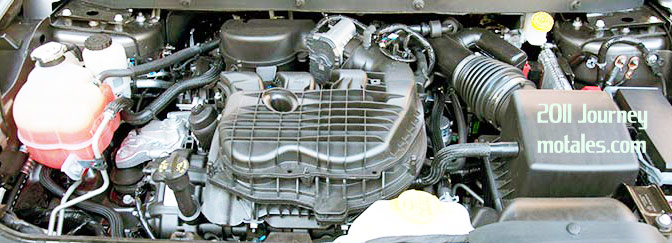

Replacing every other Mopar V6, the Pentastar ran on regular fuel in its 3.0 liter, 3.2 liter, and 3.6 liter forms, driving front, rear, and all wheels. The Pentastar debuted on the 2011 Chrysler 300, Dodge Challenger, and Dodge Charger, boosting output by over 40 hp, but didn’t really “wake up” on those cars until it was coupled to the ZF eight-speed automatic on the 2013 300/300C and Charger, then on the 2015 Challenger. Its performance in the lighter Chrysler 200 and Dodge Avenger were impressive from the start.

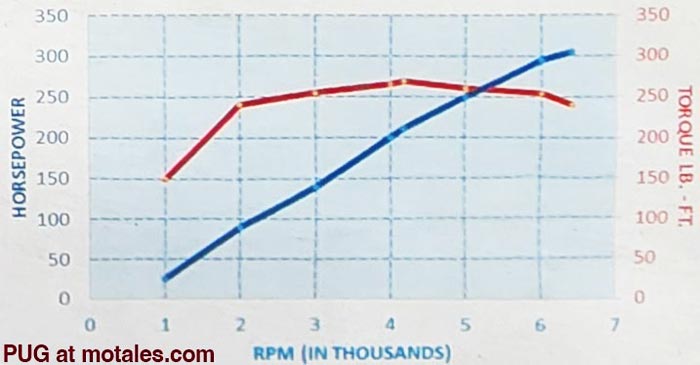

90% of torque was available from 1,600 to 6,400 (1,800 to 6,360 on the Challenger), building smooth and steady power as the revolutions went up. With the eight-speed or nine-speed automatic, it happily powered cars at highway speeds at quite low revolutions; the Pentastar returned a reliable 31-34 mpg at 75 mpg in the full size Chrysler 300, for example. People could be forgiven for thinking the 292-hp (in that application) six was actually a V8 engine; it wasn’t that long ago that nearly-or-over 300 hp was unusual from a V6.

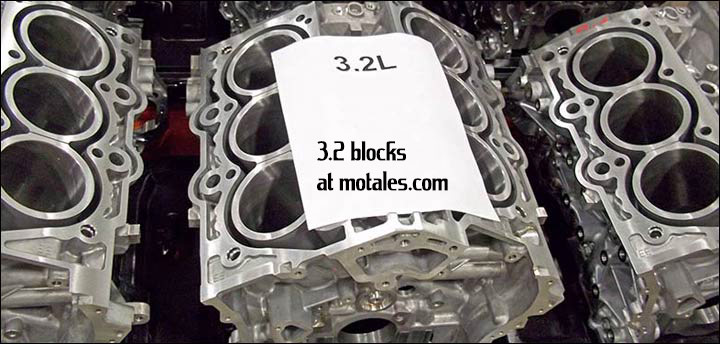

There were three variants of the 3.6, but more were planned. The 3.0 was for cars sold in Europe; the 3.2 was for the Jeep Cherokee; and the 3.6 (3605 cc) was for everything else. The 3.0 disappeared when Chrysler left Europe, and the 3.2 ceased production when the Jeep Cherokee “KL” ended in 2023. At the dawn of 2024, two factories were making two versions of the 3.6 liter version—the original and the Pentastar UpGrade (PUG).

Ferrari modified the Pentastar for the Maserati Quattroporte and Ghibli; with twin turbos and very exacting machining, its output rose to 404 horsepower. Their inability to squeeze out more power may explain why the Mopar turbo and supercharged versions never made it into production. Maserati later moved to Ferrari engines, but the Pentastar stayed on for Dodge, Chrysler, Jeep, and Ram; it was reliable, quiet, and still a good power-and-economy powerplant.

The Pentastar was largely state of the art when it was launched, and won spots on Ward’s Ten Best Engines list for several years. Even its weakest 3.6-liter version was more powerful than any past Chrysler six; it also had better fuel economy, less noise, and easier maintenance.

The Pentastar remains the only gasoline V6 used by Chrysler, Dodge, Jeep, or Ram, and will probably be their last V6.

The Pentastar UpGrade (originally dubbed PUG but renamed PSU, PentaStar Upgrade, by Bob Lee) was harder to repair and cost more, but it brought 15% more torque at engine speeds below 3,000 rpm for better drivability and less shifting; gas mileage increased by over 6%. On the Grand Cherokee, horsepower rose from 290 to 295 (on the Chrysler 300 the original engine was rated at 292 hp while on the Challenger it went up to 305 hp).

Revisions include a two-speed variable valve lift to cut pumping work at low speeds, increasing fuel economy by up to 2.7%. A torque-driven cam phasing valve timing system cuts oil demand and increases the system’s range from 50° to 70°, cutting knock during hot starts and making better use of the stop-start system. The new intake manifold required engineers to recalibrate the valve timing system as well; finally, the computer now looked at the rate of change in the accelerator pedal, making aggressive changes when it sensed “pedal to the metal.” (This change did not require a new engine design.)

| 3.6 | PUG | |

|---|---|---|

| Power (most cars) | 292 | 305 |

| Torque (most) | 260 | 269 |

| Compression | 10.2 | 11.3 |

The upgraded Pentastar (PUG) has cooled exhaust gas recirculation to eliminate knocking; a new intake manifold with longer runners for higher torque; and heads with higher tumble intake ports and shrouded combustion chambers so compression could be raised. New fuel injectors have eight holes for better atomization, and HG-R1 on the timing drive guide faces (the first production engine using HG-R1) reduced friction. Other changes included new valve springs, low-tension piston rings, and piston pins with a diamond-like carbon coating.

New 100-millijoule high-energy ignition coils with platinum spark plugs extended spark plug life.

Redesigning parts cut the engine weight, despite 13 pounds of added content; the lightest PUG weighed 326 lb (vs the original Pentastar at 330 lb). One strategy was thinner walls on some die-cast components. Windage tray weight was slashed by 19%. The two-piece oil pans were eliminated except on Trail Rated Jeeps. The main bearings and crankshaft pins were trimmed, cutting six pounds and reducing friction.

From the start, people criticized the plastic mount for the oil filter. The oil filter design itself was quite clever, slashing waste and long-term cost, but the mount was too easily cracked when mechanics or owners (predictably) overtorqued the case.

It was not a design flaw, but a recall covered a massive number of Pentastar engines for damage to their valvetrains. At fault appeared to be parts made from lower-than-specification metal, in what appeared to be a running change to save money (by making the tooling last longer, by buying a cheaper metal, or both). We could not get a confirmation or denial from Stellantis on this, but factory guidance and mechanics’ feedback suggests it. The repair appears to consist of harder camshafts with revised rockers, lifters, and oiling modules.

These paths were planned when the Pentastar was still being developed and documented in 2006:

The Pentastar replaced all prior V6 engines, in a phrase-out process with the last survivor, the 3.7, ending production in August 2012. The 4.7 liter V8, which produced similar horsepower (with higher torque), was also dropped. The Pentastar was reportedly cheaper to make than past engines, and was also cheaper than GM’s contemporary (at launch) V6.

Pentastar engines have an open deck design, with oil return holes below the head bolt holes. This made manufacturing cheaper, at the cost of upper cylinder support; the aluminum slant six had also used an open deck. A turbocharger could be added without changing the deck machining. Compared with the 3.6, the 3.2 used lower-friction pistons, narrower sleeves, and smaller journals and main bearings, and different rods, for much less rolling resistance and higher gas mileage. The 3.2 and 3.6 had the same blocks. All Pentastars had a chain drive instead of a timing belt, and used regular 87 octane fuel.

There were only two head designs at launch, despite there being four variants (rear drive, all wheel drive, front wheel drive, and Wrangler). There were also only two intake manifolds and one set of internal components, including cam and pistons, according to an SAE article by Paul Weissler. The Challenger’s 305 horsepower, the highest on any Pentastar except for the Ram 1500, was created by a better intake air system, which increased airflow from 214 to 220 g/s. The engine was designed to run on E85 without hurting performance or emissions.

The major innovations were:

Ports and manifolds. The intake valve was a single piece of forged heat-resistant (martensitic) steel. Exhaust valves are two-piece designs, with a forged austenitic head welded to a martensitic stem, and both have a nitrided surface treatment to prevent scuffing (except at the tip and lock grooves). Roller rocker arms, pivoting on stationary lash adjusters, activate the valves, which use three bead lock keepers to help rotation and retain the springs.

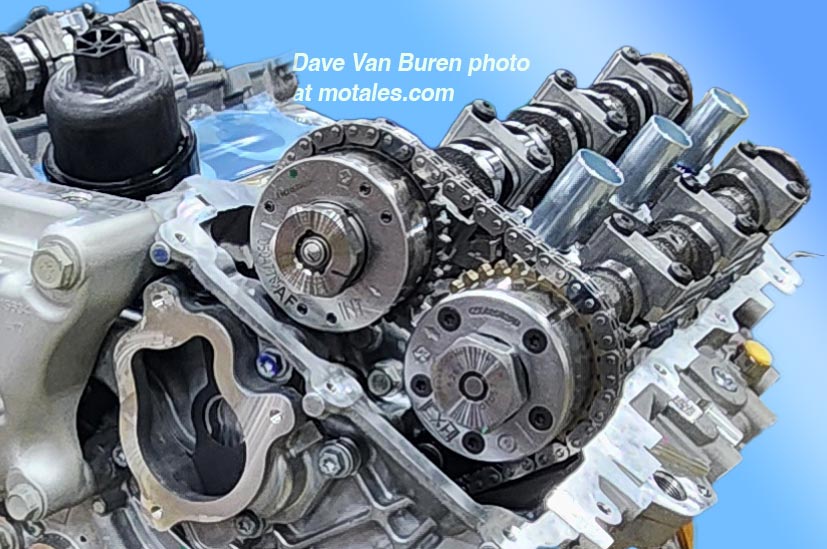

Timing. The timing drive uses four chains, one of which, with a spring-loaded tensioner, drives the oil pump. The other three drive the camshafts. Primary and secondary camshaft chains use oil pressure controlled chain tensioners; the left secondary uses a ratchet, the right secondary and primary do not. Chain guides and tensioner arms alike are made of glass-filled nylon, with nylon wear faces. The valvetrain uses roller rocker arms with hydraulic lifters. The Pentastar V6 is an interference design; it has valve reliefs but only for clearance under normal conditions.

Pentastar V6 cylinder heads. Aluminum heads had unique left and right castings and integrated exhaust manifolds. The valves have pressed-in powdered metal guides. Thin-walled spark plug tubes are pressed into place and could easily be damaged by careless mechanics.

Engine block. The high-pressure die cast aluminum block has cut slots between each cylinder and cast steel cylinder liners. Three piston oil cooler jets mounted to the block (each cools two pistons) were attached to the main oil gallery. Four powdered metal main bearing caps are cross-bolted, with directional arrows molded in. The main bearing caps are a cross-bolted, 6-bolt design. Three oil drain back drillings are on each of the cylinder banks, and two knock sensors are in the block valley. The engine accessories are bolted directly to the block, cutting vibration and weight versus using brackets. The serpentine belt used a tensioner.

MAP sensor. Instead of a mass airflow (MAF) sensor, Chrysler uses MAP sensors and computer algorithms, which saves parts money though it adds tuning costs.

A vane-type variable displacement oil pump adjusts the flow rate and pressure, and is controlled by a solenoid so that below 3,500 rpm, it conserves energy by using low pressure. A force balance mechanism inside the oil pump makes the pumping chambers smaller when the oil is cold, which also saves energy. A mechanical relief valve dumps oil into the sump when needed, for example in a cold start with high engine speed.

At launch, Chrylser recommended oil with an ILSAC standard of GF5 and a change interval of 8,000 miles under normal driving conditions.

Oil pressure and temperature sensors are on the oil filter housing assembly; the oil cooler (a plate-style coolant to oil heat exchanger) is mounted to the oil filter housing. The Wrangler was designed to keep oil within reach of the pump while at steep angles, had a higher-mounted alternator and unique intake for water crossings.

The nodular iron crankshaft has an 83% increase in fatigue strength over prior iron cranks, due to the rolled fillet process. The crankshaft has four bolts on the main bearing supports; two more are cross-fitted in the main bearing caps providing an extremely rigid bottom end. A structural windage tray reduces oil splash on the crankshaft and cuts power losses from the reciprocating assembly.

Cylinder heads were made of T7 heat-treated aluminum; intake valve diameters are 39mm with 17 degrees relative to the bore axis. Exhaust valves are 30mm in diameter and canted at 18.8 degrees. Combustion chamber volume is 52.7cc.

Torque actuated cam phasers use the natural action of the valve springs to move into position; their small size allows the camshafts to be spaced very closely together for optimum valve angles and combustion chamber geometry.

A lightweight composite intake manifold, pioneered on the Neon, feeds into a 74mm throttle bore. Spent gases exit through an integral exhaust manifold that is cast into the cylinder head, cutting weight and bringing a broader range of stoichiometric operation, reducing fuel consumption during mountain grade and trailer tow driving.

Meeting future emission standards does not require Exhaust Gas Recirculation (EGR); on launch it met Federal Tier 2 BIN 5, Ultra-low Emissions Vehicle II, and Euro6 standards.

Spark plugs, good for 80,000 miles, are installed at the end of a tube which is pressed into place and cannot be removed. Cylinders are numbered front to rear; the right bank has pistons 1, 3, and 5, the left 2, 4, and 6, with a 1-2-3-4-5-6 firing order. The serial number is on the left side of the block, at the transmission flange.

The Pentastar reportedly did 7% better in fuel economy than the Nissan 3.5 engine for the same power output, before launch. The planned cylinder deactivation system would have dropped three cylinders at a time when they were not needed.

The 60° engine had a length of 503 mm (94mm shorter than the 3.7 and 34 mm shorter than the 3.5). The bore and stroke were 96mm by 83mm. Pistons have a reduced skirt area to cut weight and friction. Piston cooling jets are fitted to each cylinder, spraying oil onto the piston to prevent detonation, control heat, and allow MDS. The smaller 3.2 liter was created by using thicker cylinder liners, rather than by having smaller bores.

Fully dressed, the new Pentastar V-6 is 94 pounds lighter than the 3.7-liter engine and 42 pounds less than the 3.5-liter. On the Jeep Grand Cherokee, horsepower increased dramatically from 210 horsepower to 290 horsepower (38%). The Charger, Challenger, and 300C gained 42 hp, rising to 292 horsepower. The engine was originally rated at just 280 horsepower; engineer Phil Jansen wrote, “The engine team did a fabulous job of increasing horsepower and delivering added fuel efficiency in the final phase of development.”

The die-cast blocks were made in both Mexico and Kokomo. Camshafts used in Trenton were made in Trenton starting in 2012; before then, they were made by a vendor in Mexico. Chrysler re-opened part of the Trenton North plant to make Pentastar parts, taking over from another Mexican supplier. Some of the old 3.7 liter production equipment was moved to Trenton to make the new engines; the millionth Pentastar was made on January 27, 2012. Kokomo made the Ferrari blocks, too, which were machined in a separate area at Trenton (Michigan).

The sand-cast heads are washed and inspected before assembly; one worker wrote, “They use an 80 horsepower motor with a 2,500 psi pump about the size of a small diesel motor. To say they come out clean is a gross understatement. The only ‘dirt’ problems I can remember was, a couple of times, having oil pump relief valves sticking with aluminum chips from the vendor — who had all Hell to pay because of it.”

The Trenton Engine South plant which makes the Pentastar has flexible CNC-based machining, volume-bundled parts purchasing, and standardized tooling; many parts were machined in Toledo. Trenton South was the fourth auto manufacturing facilities to receive a LEED rating of any kind, and when first built, the only engine manufacturing facility in the world to achieve LEED Gold. In practical terms Chrysler likely saved $1.25 million per year in energy, cut CO2 emissions by 12,000 metric tons per year (or 1,000 homes worth) and saved 1.5 million gallons of water per year.

David Van Buren wrote that they used “overhead gantry type robots in the machine shop. The whole robot can be easily replaced by unplugging, unbolting it and changing the end of arm tooling with minimal lost production time. My observation of the robots in the machine shop told me they appeared to be all about the same type and size.”

He added, “Each major component has an individual identification number with a stamped on it and a radio frequency tag. They know what time each part went into a particular machine. If there is a problem with a part, it’s easy to find! They know what parts are on what engines!”

Because die-cast blocks can be porous, resulting in leaks, the high-pressure die manufacturing process has a higher scrap rate than sand casting. During the cubing process, parts were tested for leaks and scrapped as needed; they may have all been impregnated with silicone sealer. Allpar’s “atwork” wrote, “After machining at the engine plant, it is possible that more porosity is created. Parts are leak tested at the engine plant as well (and possibly impregnated). The high pressure die cast can cause problems; while allowing better dimensional tolerances than sand or lost foam casting, it is more prone to porosity and therefore leaking. Once the high pressure die cast process is worked out, it is very stable, but this takes a lot of development time.”

Another Allpar member confirmed to have worked at Trenton, “Mad Duck,” added:

Leak tests are done with low pressure air, and the leak rate is measured over a given time. Air leaks through smaller paths than oil or antifreeze and water, so this is a tougher test. Silicon impregnation was used at Trenton Engine starting with the 3.5 liter aluminum engine; it may have been used earlier on the aluminum heads of the 2.2 / 2.5 liter engines. It works and has stood up over time. I don’t remember any short or long term problems with this process.

Engine blocks and cylinder heads had freeze plugs partly for cleaning out the metal chips from machining. The dark sides are leaks and noise-vibration-harshness problems; a freeze plug is just like a drum for emitting noise. The Pentastar blocks and cylinder heads have no freeze plugs! No leaks, no noise, but getting them clean of chips is a lot harder.

The parts are now using RFID tags and are marked with build dates and times, and a unique serial number for each major part; they are marked using a unit with a resemblance to a dot-matrix printer.

In 2011-12, some engines had cylinder head failures due to overheating of the #2 cylinder’s valve seats. The problem was indicated by the “check engine” light. The fix was hardened valve guides and seats, entering production in June 2012. Most affected vehicles were Jeep Wranglers; a service bulletin was issued for Wranglers built before January 24, 2012 (MDH 0124XX) to prevent “false positive” check-engine lights.

A build date of 2062 (the 206th day of 2012) stamped on the cylinder head shows that it is one of the newer types. The part numbers of the new heads are RL141353AC or higher (left side) and RL141352AD (right side). Update: Some 2013 model year vehicles may have the old heads.

Chrysler extended the warranty on the left-side heads of 2011-12 (and some 2013) Pentastar engines; bulletin D-14-12, dated June 10, 2014, tells dealers which vehicles are covered — for ten years or 150,000 miles, whichever comes first. At this point the warranty is over.

Some exhaust cam phasers on the early 2011 engines set a check engine light.

Chrysler changed the oil filters and cap O-rings for the 2014 model year, from 68109834AA to 68191349AA; this coincided with changes to the oil cooler. This may not have been a repair issue but an attempt to commonize parts with the VM diesel. Using the wrong part will cause an oil leak.

The V6 takes six quarts of oil, but it may only seem to take five to the backyard mechanic. The main reason is because it takes a long, long time for the oil to settle. To check the oil, the company recommends giving the car 30 minutes for the oil to settle to the bottom; checking the oil with the car freshly parked and shut off can lead owners to overfill it. Oil should not be added while it’s in the normal range—only if it’s below the safe range on the dipstick. The same goes for oil changes—the car needs around half an hour to drain the oil, or only five quarts may come out. One owner reported on Allpar that he filled his to read a half quart low after an oil change; the next morning it would show full or slightly over! So filling to the top line would actually overfill by up to a quart, which is not desirable.

The serpentine belt on early engines must be carefully routed; the water pump is driven off the back of the belt, so an incorrect routing will result in the pump going backwards. Later models use electrohydraulic pumps in a different location, and then have electric power steering rather than electrohydraulic or hydraulic power steering.

* Thanks to Erik Latranyi for correcting the 3.2 end date.

Cubic inches of 198 and 220 cid parallel the common-block slant six’s 198 and 225 cubic inches (the original slant six was 170 cubic inches).

The Ram 1500 rating increased for 2025, from 305 hp. The Challenger started at 292 hp and rose to 305 hp later.

| HP | Lb-ft* | MPG** | |

|---|---|---|---|

| Dodge Challenger | 305 | 268-270 | 18/26 |

| Chrysler 300, Dodge Charger | 292 @ 6,400 | 260 | 19/31 |

| Charger Pursuit | 291 @ 6,400 | 260 @ 4,400 | 19/26 |

| Caravan, Avenger, old 200 | 283 @ 6,400 | 260 | 17/25 |

| 2015-17 Chrysler 200 | 295 @ 6,350 | 262 | 19/29 |

| Grand Cherokee 5-speed | 290 @ 6,400 | 260 | 16/24 |

| Durango (2014) | 290 @ 6,400 | 260 | |

| Ram 1500 | 310 @ 6,400 | 269 @ 4,175 | to 18/25 |

| Cherokee AWD (3.2) | 271 @ 6,500 | 239 @ 4,400 | 22/29 |

| Pacifica | 287 | 262 |

* at 4,800 rpm unless otherwise specified

** 2014 unless otherwise noted

| Specification | Mopar 3.6 liter V6 Engines |

| Material | 60° V6 with deep-skirt aluminum block and heads |

| Valves | Dual overhead cam (DOHC) Four valves per cylinder with 24 valves Chain driven Roller finger followers; hydraulic lash adjusters Dual independent cam-torque actuated phasers |

| Measurements | Fully metric |

| Bore x stroke | 3.6: 220 cid, 3.78 x 3.27 (96 x 83 mm) 3.2: 198 cid, 3.58 x 3.28 (91 x 83 mm) |

| Fuel injection | Returnless, sequential. |

| Compression | 10.2:1 (Original 3.6) |

| Fluids | 6 quarts 5W20 oil 14 quarts antifreeze; regular gas Regular 87 octane fuel |

| Firing order | 1-2-3-4-5-6; cylinder is #1 in the right bank |

| Pistons | Cast aluminum alloy, 354-364 grams |

| Intake valve timing | Opens at 2° ATDC Closes at 82° (ABDC) or 262° (ATDC) 260° duration, 128° centerline |

| Exhaust valve timing | Opens 59° (BBDC) or 239° (BTDC) Closes 12° ATDC 251°, duration, overlap 10° |

Sources: Willem Weertman, Chrysler Engines, SAE; Allpar.com; press kits; conversations.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos