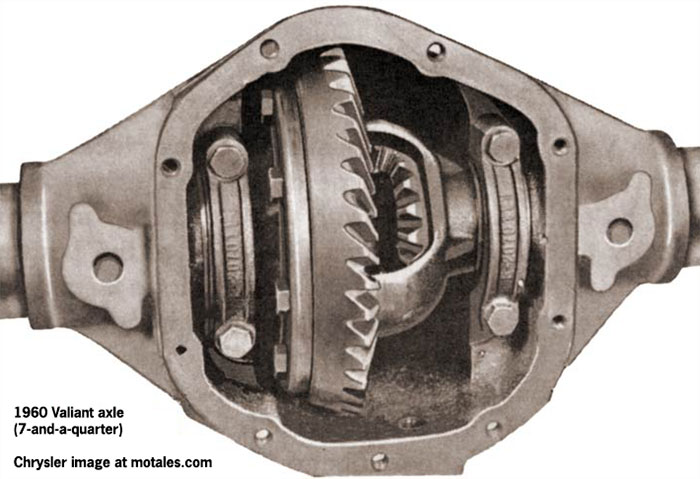

The axle was, surprisingly, one of the items on a car which required the longest lead to set up tooling back in the 1950s; so the Valiant axle was planned before the details of the engine or transmission were known, in early 1957. Evan Jones was manager of the axle lab and Al Bosley was a fresh engineer.

Evan sketched the axle out and wrote down the specifications, and then the drafting Department would convert them into drawings for manufacturing and purchasing; it was mostly modifying the existing design for new power levels or tracks (widths). For the Valiant axle, they knew almost nothing about the car it was being designed for—the pinion length, track, power, or weight. They only knew that it would be a light, small car.

Evan had found out that the people who actually made the axles down in Lynch Road were not happy with them, and Evan and Al decided to use a carrier tube design to get more flexibility on the track, more rigidity, and easier manufacturing. It also made brake work easier.

Chrysler had long used a two-piece drive axle arrangement with tapered outer end shafts that fit into a separate flange, and a nut and a key that held it together. They were very hard to get apart to get to the brakes or change axle shafts. Al Bosley proposed using a flanged shaft like GM and Ford, rather than the Chrysler design, used on every car since 1924, of straight axles with a taper and a bolt-on flange.

The new design had a hot upset process where the end of a bar is heated and then forged back on itself to create a larger flange. The people at the axle plant said that it would be a little more expensive but they could still do it, and it would be better overall for the car. The drawings were released in mid-1958 to the Lynch Road axle plant; they started purchasing and designing the tooling, ordered the gear cutting machines, got the casting patterns done, and did everything else they needed.

Al Bosley said that there were two things that he wishes that they had done better. First, neither of them realized they would need to run high power through that axle; the differential gears in the pin were too small.

The other thing that he wishes he had done differently was something that they did to save weight. In the 8 3/4 inch axle, the main drive gear pumps oil up to the front bearing along a passageway in the top of the axle casting; there is a little void along the bottom of the rear bearing so the oil can get back again. That void wasn’t designed into the (earlier) 7 1/4 inch axle on the original Valiant; it turns out that both bearings didn't get enough lubrication so the axle ran a little hot; but the weight and cost savings justified it, in his opinion.

Chrysler decided to use a smaller bolt circle to hold the wheels, because it makes the upset process easier and saves weight. The Valiant has a smaller bolt circle than the Chevy or Ford did, but had five wheel bolts instead of four on the Chevy and Ford. The wheelmaker said it was not a problem.

Thanks to Al Bosley, who passed this story on to me when he was in his 90s, and Peter, do who did the recent Mopar axle presentation.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos