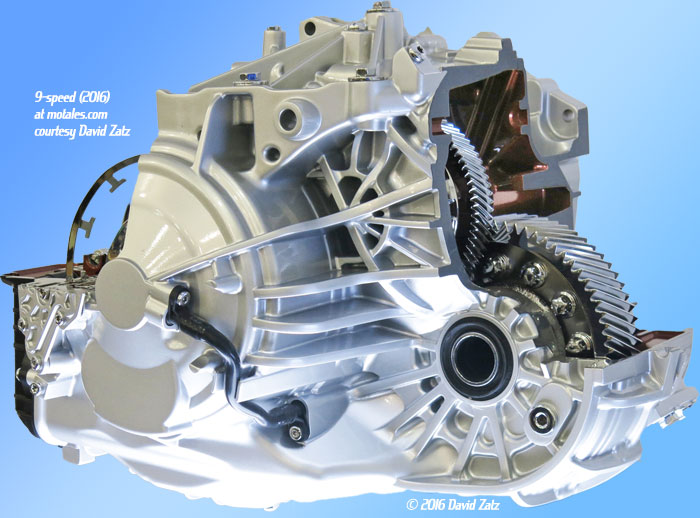

ZF revealed the world’s first nine-speed transverse-layout automatic transmission in June 2011. Production of the new “9HP” automatic began in 2013, featuring a wide gear range (9.84), which helped manufacturers to have strong acceleration with good highway mileage—they could have a quite low first gear and a tall top gear at the same time. Compared with Chrysler’s existing 62TE automatic, the new nine-speed had a much lower first gear and a much taller top gear. The range between gears was so wide that some customers complained they never actually got to use ninth gear.

| 9HP | 62TE | ||

|---|---|---|---|

| First | 4.71 | 4.13 | |

| Second | 2.84 | 2.84 | |

| Third | 1.91 | 2.28 | |

| Fourth | 1.38 | 1.45 | |

| Fifth | 1.00 | 1.00 | |

| Sixth | 0.81 | 0.69 | |

| Seventh | 0.70 | - | |

| Eighth | 0.58 | - | |

| Ninth | 0.48 | - |

Chrysler’s first nine-speed vehicle, the “KL” body Jeep Cherokee, was delayed by months while engineers tried to resolve or at least mask shifting issues in software (as did their counterparts at Honda and Land Rover, who were also adopting the nine-speed). The problems were large enough to get extended warranties for owners of 2014-15 Cherokees and 2015 Chrysler 200s.

As part of the ability to build the transmission in-house, Chrysler gained the right to change the internal hardware. ZF and Chrysler had done this before, when Chrysler had started buying eight-speeds from ZF and then started making them in-house, with ZF’s permission to alter the design. With the eight-speed, they changed the design to match Kokomo’s equipment and methods, and to make production of many more transmissions per year practical—and, later, to build in extra capacity for Ram pickups.

Making the ZF nine-speed in-house gave Chrysler some control over the hardware, resolving most of the problems in the 2016 and 2017 model years.

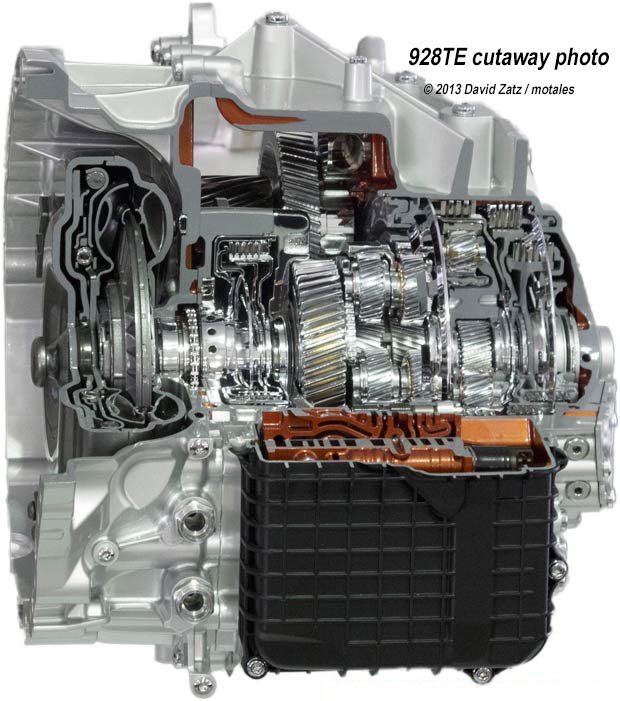

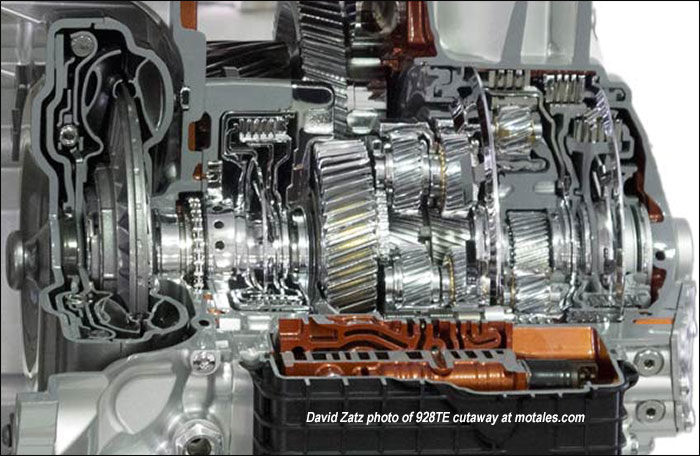

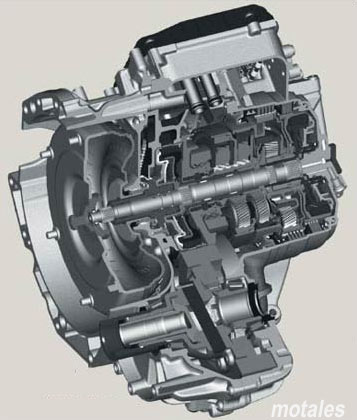

ZF had two versions of the nine-speed, with torque capability of 280 Nm (206 lb-ft) and 480 Nm (354 lb-ft). The Chrysler names for these two versions were 928TE and 948TE; the latter decodes as “9 forward speeds, 480 Nm, Transverse, Electronic control.”

Chrysler’s Kokomo plant and Indiana Transmission Plant #2 machined the aluminum; Indiana Plant #1 and Tipton assembled it. All this work was done in Indiana.

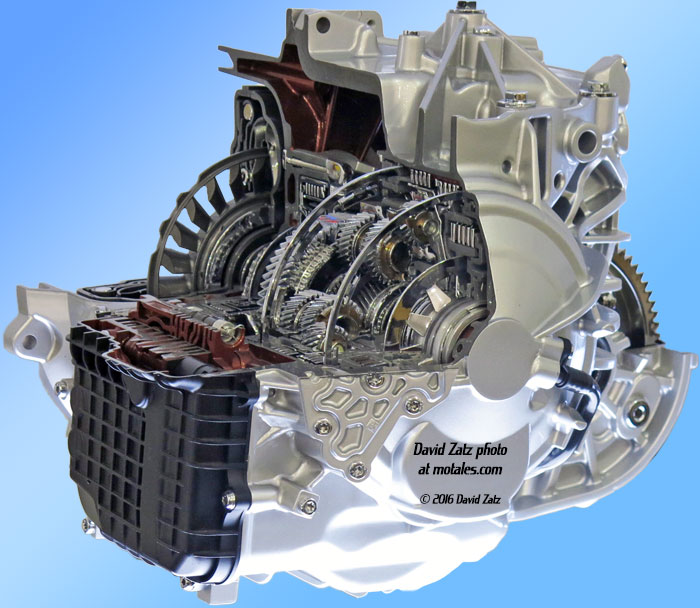

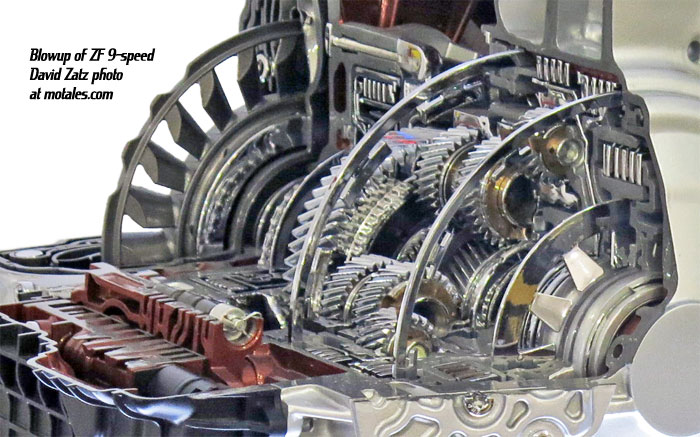

The transmission itself was quite clever, among other things having nested gear sets so the four gear sets and six shifting elements would all fit into a compact space. It had built-in capabilities for stop-start systems, hybrid use, and all wheel drive, the latter via a power take-off unit (PTU). The transmission could, with all wheel drive, power only the front wheel, provide torque vectoring with the front and rear wheels, and distribute power between the two rear wheels.

The elements were hydraulically operated, with constant meshing and two “dog clutches” to increase efficiency. The torque converter had a multi-level torsion damper system so it could lock up quickly for greater performance and economy. Response and shift times were both incredibly fast—150 ms of response time and 450 ms of downshift time.

The shifting points and shifting dynamics were flexible via the computer, which allowed direct gear-skipping shifts, e.g. from second to fourth. One controller, dubbed ATSYS, covered clutch controls, adaptation, and transmission protection; another, ASIS, controlled driving strategy—the actual gear choices. The hydraulics and electronics were controlled by separate computers.

The stop-start support could be done without an extra oil pump; only one friction shift element had to be closed on restart. A hybrid setup was possible by replacing the torque converter with an electric motor.

The fluid was the same as the ZF eight-speed: Shell L12108, ZF LifeguardFluid 9, ZF Lifeguard Hybrid 1, Mopar/Stellantis “8 and 9 speed transmission fluid” (part 68218925AB), or equivalent. Other fluids for the same transmissions are home-branded by BMW, Honda, Jaguar, Land Rover, and Mercedes.

While Chrysler was quite early to use eight and nine speed wide-range automatics on mainstream vehicles, it was a clever calculation. The transmissions, expensive as they were, allowed for greater fuel economy and acceleration at the same time; enhancing engines to achieve these goals would have been difficult and expensive, if possible. The eight-speed had replaced a Mercedes five speed automatic of similar or greater cost, making it an easy choice. The nine-speed replaced a relatively inexpensive Chrysler transmission which, though smooth, was fairly inefficient; this is a tougher choice in terms of cost, but in theory it should have given new vehicles quicker acceleration and better fuel mileage.

Early teething problems resulted in mechanical changes for the 2016 models, as well as numerous software updates which covered most outstanding issues. In some cases, software updates resulted in rough shifting as some dealers skipped the PROXI alignment step, which updates information in all the car’s systems.

PROXI alignment was mandatory when a module was replaced; one telltale (though it may not always appear) is a blinking odometer. This was specifically called out in the instructions, but still not always followed by techs trying to save time.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky

ZF nine-speed transmissions used by Jeep, Dodge, and Chrysler.