When Chrysler president K.T. Keller was asked to make 1,500 tanks in two years, without ever having seen one, his immediate answer was “yes.” The next day, Keller assembled a team; and by the end of one week, that team had been to Washington, DC, seen prototypes in Illinois, and started studying 186 pounds of blueprints.

When the team understood how it would make tanks on assembly lines, it set a price of $33,500 per tank (in 1940 dollars; that would be $672,747 each in January 2022). The government bought land in rural Warren Township, 17 miles from Detroit, and paid for the buildings (Chrysler charged $4 for designing them) of the new Detroit Arsenal. FDR later called Detroit “the arsenal of democracy;” Chrysler would live up to that, making more than half the American tanks of World War II.

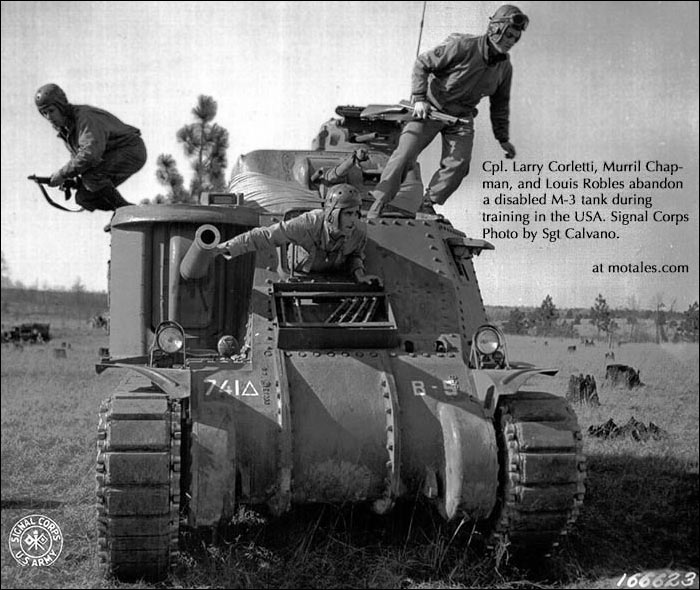

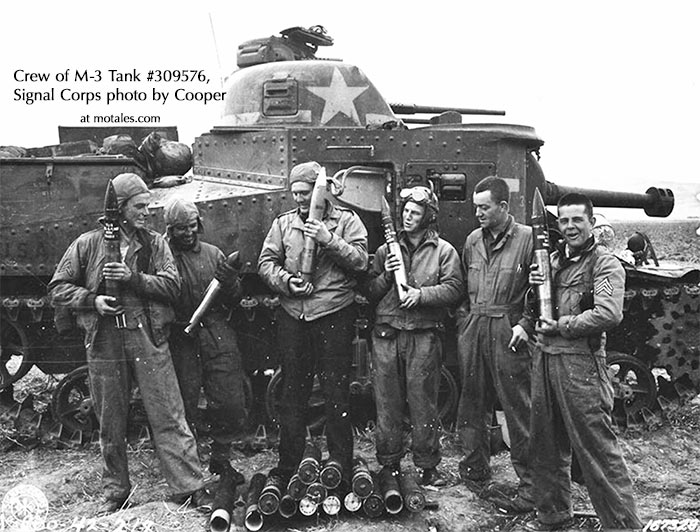

Two months later, the Army declared its prototype to be obsolete and started working on the M3—which still had serious compromises. Its main 75 mm gun, capable of using armor-piercing or high explosive shells, was mounted in a sponson on the side. The turret on top had an AA .30 caliber (7.6 mm) gun for anti-aircraft use; a 37 mm gun was added as well as various other .30 machine guns on the tank. The tracks, wheels, rollers, and most of the vertical volute spring suspension were taken directly from the M2; steering was by differential braking.

The tank was tall because the driveshaft went under the turret, and to fit an air-cooled Wright radial aircraft engine made by Continental—which made it an easier target. Late versions of the M3A1 had a smooth cast hull; the M3A2 and M3A3 had the welded hull with sharp angles of the orignial M3. The main engine powered the electro-hydraulic turret system, which could go all the way around in under 15 seconds; the secondary gun was positioned with hand wheels.

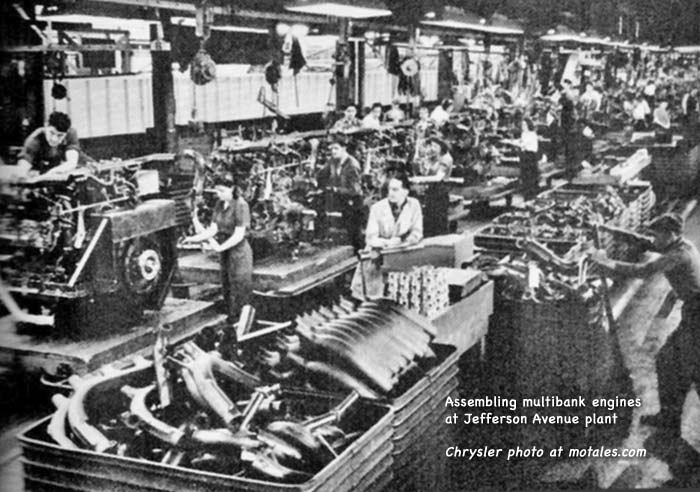

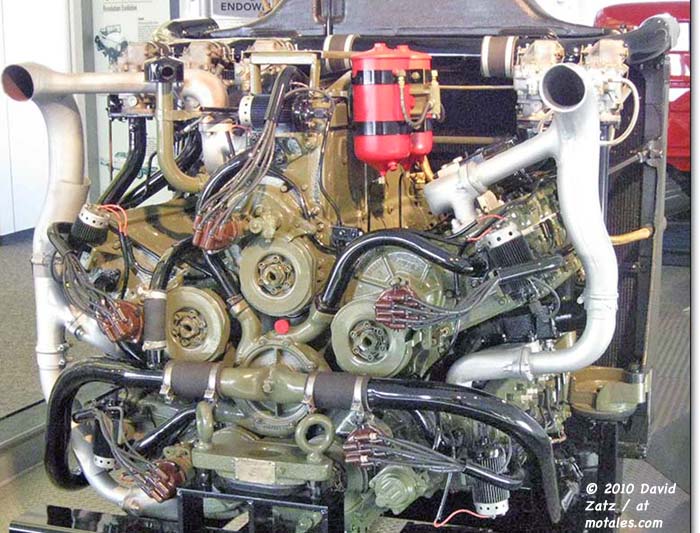

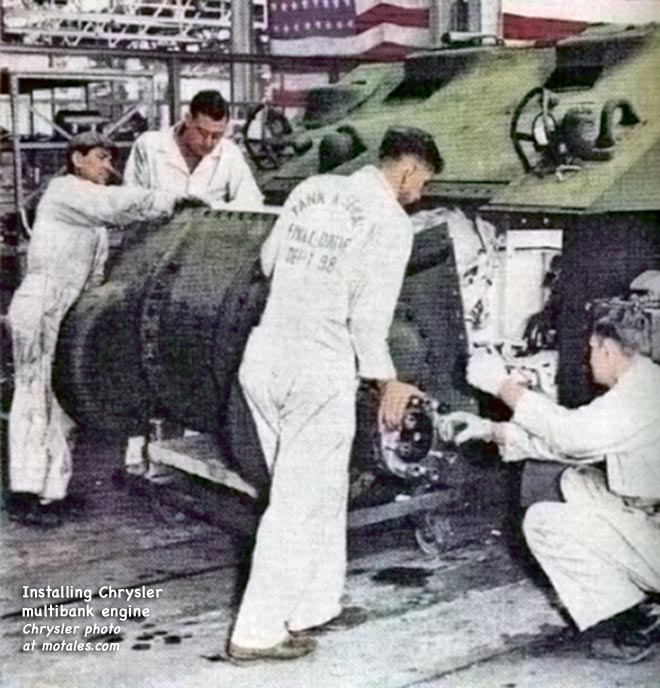

Late in the game, the Army realized it would be short of engines and asked several companies for a solution. The result may have been Chrysler’s most famous wartime engine; with no way to get tools and dies made for mass production, engineers modified five of their straight-six car engines and arranged them around a common crankshaft, creating a 30-cylinder multibank engine nicknamed “the eggbeater.” The 21-liter engine, originally producing 470 horsepower, was rushed into production with as few changes as possible; 109 of these were put into the M3A4 models.

Despite the time rush, the Eggbeater or Multibank engine were put into 7,500 new tanks—and not just M3s. The Eggbeater had low maintenance needs, was easily serviced, had good fuel economy compared with the Wright, and could run for long periods of time without losing power, even when run on low-octane fuel. The Chrysler multibank engines stayed on until 1943, only losing out to diesels.

The M3 prototypes started production before the heating plant was done. Small kerosene heaters and a rented steam locomotive warmed the air a bit, but workers had to wear coats and gloves—and had no overhead cranes yet. Yet, 200 people got together to build the prototype, then break it back down and start over as a test of the assembly line methods. Finally, in April 1941, the building was finished and the pilot tank was handed over to the Army in a ceremony with 2,000 people in attendance, including quite a few dignitaries.

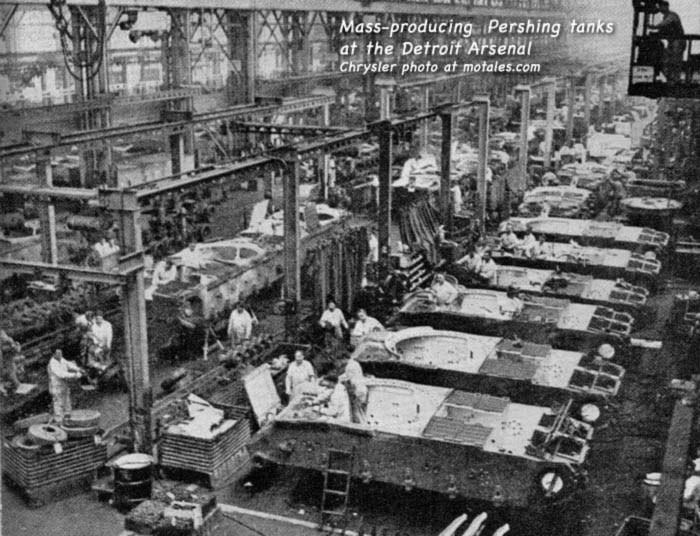

The assembly line was finally done in June, and all the tools had arrived and been installed by early July. The company hired 200 workers a day as they staffed up—and the government added over a thousand tanks to their order. Six tanks came off the line in July as the new tools were tested and staff kept coming in and getting trained.

Plant manager B. E. Hutchinson, taking a break from his usual job of being Plymouth vice president, took charge in August; he moved the schedule to six days per week, three shifts—24 hours a day—but refused to use the Army’s desired 7-day-a-week schedule because he felt it would be unsafe. The workforce reached 6,000 by the end of the month, working on three assembly lines (out of an eventual five).

There were two series of the M3, one made for the British and Russians, dubbed the Grant after the Civil War general and later President; and the Lee, named after opposing general Robert E. Lee, made by Chrysler and by American Locomotive. The second batch of Lees, the M3A1, had a rounded hull, lower-profile turret, and thicker armor; they only made 12 M3A2s, and then a group of M3A3s with the old welded hull, dual GM diesel engines, and non-moving side doors.

Chrysler finished its 500th tank one week before Congress declared war, in December 1941. Tank #1,000, which would have finished the original order, was done in early February—months ahead of schedule. By March, production was up to 366 per month. On July 10, 1942, roughly the deadline for the first thousand, Chrysler made its 3,100th tank.

Production continued at high levels despite a stream of changes, many at the request of the British troops using their products; this would continue thoughout the war. A number of different variants and changes would affect the M3 and M4 as new uses were found or as shortfalls became apparent. The British even sent hundreds of tanks back for refitting, as they improved on the original design.

Overall, the M3 was generally a success; the British used them throughout their effort to recover Africa from the Nazis, until the Germans came out with their Panzer III and IV designs. At that point, they were sent down to India and Burma, used in roughly equal numbers by Australians and Indians—with great success. Both the British and the Russians made their own tanks as well, but neither could build as many as they needed.

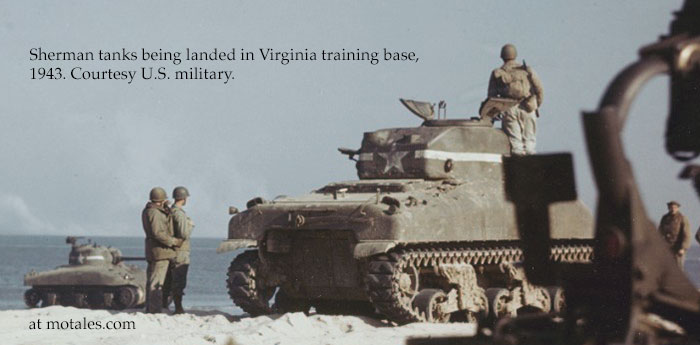

The M3 was not an ideal tank, and designers quickly got to work on a better one. Now, the Army wanted Chrysler to make 750 M4 tanks per month; Keller agreed immediately, though they had to stretch the 564-meter assembly line to over 700 meters. Chrysler did not make the first M4s—that honor went to the Lima Locomotive Works. The first tanks went to the British Army. In the end, 11 factories were pumpnig out the tanks, including Chrysler, GM, and numerous railroad makers.

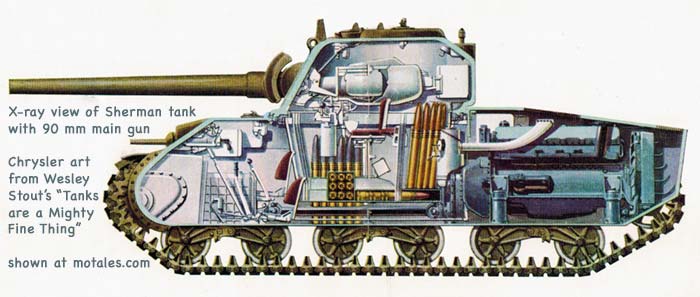

The M4, dubbed the “Sherman” after General William Tecumseh Sherman (continuing the Civil War theme), was based on the medium-sized Grant / Lee; but the Sherman tank had a full traversing central turret, with a one-axis stabilizer which kept the gun roughly where it was aimed so when the tank stopped to fire, it didn’t take long to get it into position (it could be fired while moving, without much accuracy). The turret held three crew members, in moveable seats, while the others sat in the front of the hull. They too had intercoms and radios; they also had five periscopes to provide each soldier with outside views, and, in early models, direct vision slits (abandoned because they were vulnerable to bullets).

Starting with the M4A1, Chrysler used a cast upper body, ending the visible proliferation of welds and rivets; the lower hull was still bolted or welded. The rounded portion of the front was made from three bolted steel plates. Still, it had the same transmission, shared some of the same engines, and had many other parts in common. The vertical volute spring suspension (HVSS) was changed to a wider, horizontal vertical volute spring suspension (HVSS) late in production; this was originally designed for the heavy T23 (in late 1943), but was also phased in for Sherman tanks through 1944 to prepare them for high velocity 90 mm main guns and to work better in mud. Duckbills were added to the outside of the tracks (and later, to the inside) as well, also to deal with mud. The M4A4—the British Sherman tank, Mark V—was made from 1942 to 1943 by Chrysler, with the multibank engine; while its armor was lighter than other M4s, it apparently was the most resistant to attack.

In addition to better firing and armor, the Sherman’s main goals were reliability and ease of service (given how far from home it would be), limiting variants of ammunition and parts, and ease of shipping. Dropping from the M3’s almost insane ten foot height was also desirable, to make it a smaller target—easier to hide.

The Sherman had better armor and weaponry than existing German tanks (at design time), and was much easier than the German designs to service. There are still debates over whether the German tanks were superior to the Sherman; some blithely quote a 3:1 or 4:1 ratio, claiming the Americans won by sheer mass of numbers. That is true as far as it goes, but the Germans were fighting a defensive war, and could simply wait for the American approach and fire from cover; and they could “dig in” and be protected by earthworks. In addition, many of the American units’ main guns were set up to fire into fortified positions, which is a different setup than the ideal for taking out enemy tanks. All of these factors acted in favor of the Germans, and against the Shermans; and in tank circles, there are still debates over the relative strengths of each one. Certainly, the Sherman tank, when properly equipped, was a formidable foe—and the basic platform was fairly flexible. Both sides agree the tread-and-wheel design was not ideal for going through mud, and that the German designs had an advantage there.

Over time, over 49,000 Sherman tanks were made, making it the highest production tank in American history and #2 in world history (after the Soviet T-34). Special versions included a tank-hunter with open-topped turrets and more powerful guns; other versions had an armor-piercing gun and a 105 mm gun. The original M4 had bolted three-piece front “noses,” replaced early on with fully cast, rounded upper hulls. A torsion bar was tried out on the M4A2E4, but it was judged impractical.

Most M4 tanks had 75 or 76 mm main guns, but they were often refitted by guns from 105 to 380 mm, because they were attacking reinforced positions. Thousands of Sherman tanks were made with 105 mm guns which could carry high explosive anti-tank ammunition, rather than being modified. Fairly early in production, dry ammunition storage was changed to wet storage (in antifreeze) to avoid fire. Over time, tactics changes so that a heavily armored tank would take the lead position, fitted with hedgerow cutters, to discover anti-tank emplacements.

Some complained that German heavy tanks could take out the Sherman, a criticism still levelled today. It is fair to a point; the Germans fought their offensive war with medium and light tanks, as the United States did. But the Americans could not easily ship larger tanks across the ocean, nor could they land them, nor could they cross makeshift bridges. The American M6 heavy tank was not practical where the M4 Sherman was.

| Tank | Range | Engine | Production |

|---|---|---|---|

| M4 M4A1 |

120 miles |

Wright | 8,389 |

| M4A2 | 100 miles | GM | 10,968 |

| M4A3 | 100 miles | Ford | 12,571 |

| M4A4 | Chrysler | 7,499 | |

| M4A6 | Caterpillar | 75 |

As a war correspondent, John Steinbeck wrote about the feats of recovery the Sherman made possible, as wrecking yards near the front lines put parts of semi-destroyed Shermans together to make new tanks. There was tragedy in every wrecked tank, but being able to rebuild them near the front lines was a major advantage. The book Death Traps provides more details on how the tanks were fixed in makeshift repair depots, and contrasts the Sherman with the complex German models. Some of these (the Panzer II, notably) were quite threatening in combat, but they had to return to the factory for servicing and repairs; and were not designed to be driven all the way out to the front. That knocked quite a few German tanks out of action before the Allies could do it.

With the Wright-Continental engine, the Sherman weighed 66,500 pounds; it was 5.9 meters long, 2.6 meters wide, and three meters high, requiring a crew of five people (commander, gunner, loader, driver, machine gunner). Normal equipment was a main gun, a hull-mounted .30-caliber belt-fed machine gun, and a .50 caliber gun atop the turret.

Engines were hooked up to Spicer synchronized manual transmissions with five forward gears and one reverse (continuing the M3 setup). They carried up to 175 gallons of fuel and, depending on the variant, could travel for up to 150 miles at up to 30 mph.

Five different engines were chosen to power the Sherman, and Chrysler made tanks with just about all of them. The M4A5 variant was to use Chrysler’s A65 engine, developed on their own time and money; it was a 1,568 cubic inch water-cooled V-12 generating 549 horsepower at 2,400 rpm in an M4A4 tank, but requiring a ten-inch lengthening of the tank. The engine bolstered acceleration and hill climbing, with superior low-end torque, but was rejected by the Army, probably because changing the shape of the tank would complicate shipping and demand more steel. In any case, the Aberdeen Proving Grounds tested all the engine choices, including how many man-hours were required for servicing. Their goal was at least 2,500 miles of run time before maintenance.

| Engine | Hours | Power | Tank |

|---|---|---|---|

| Continental R975 | 132 | 400 | M4, M4A1 |

| GM diesel | 143 | 375 | M4A2 |

| Ford Aircraft V8 | 110 | 450** | M4A3 |

| Chrysler Multibank | 45 | 370* | M4A4 |

| Caterpillar/Wright diesel | n/a | 450 | M4A6 |

Power ratings were as of 1943; the Continental and Ford engines were tested with aviation fuel, but that was not available on the battlefield, so those engines had their compression lowered. Their listed power output was, therefore, not actually available in the field. The Chrysler multibank engine was tested with regular gasoline, and after these tests regular upgrades increased output quite a bit. The Chrysler engine was the only design to have more than one tank complete the Armored Council’s reliability tests (which included driving 4,000 miles)—three Chrysler tanks passed the test, and one GM diesel. Four Ford engines were tested and all failed, along with the Continentals. After thousands of miles of testing, the Chrysler was judged the most reliable engine—and the easiest to service. The transmission took longer than usual to service, though.

GM made many Sherman tanks from their “Fisher Tank Arsenal” (named after Fisher Body); Ford made around 1,700; and several train makers pitched in as well. It’s unlikely any made them for as little money as Chrysler, though. The first M4 was made on July 22, 1942; by the end of 1942, Chrysler had made 5,004 tanks (both Lee and Sherman)—and, since they had made so many, so quickly, they sent a $7.9 million rebate to the United States government. The executive team had a symbolic salary of $5 per year, including the president of the company.

As 1943 came to a close, while Chrysler had beaten its production schedule, other companies did not meet theirs; and Chrysler was asked to make 55 more tanks. They finished up with record production for the year of 5,111 Sherman tanks with Chrysler’s rushed-into-production multibank engine and 1,528 with Wright engines; 16 more had diesels. Chrysler also rebuilt 1,306 tanks which came back with damage or which needed modifications (in a separate facility), and built other variants and designs; for example, they made 250 T-23 electric-drive tanks (which would be developed into the Pershing). The T-23 was much faster and more agile than the Sherman, and had a larger, more powerful main gun; but none left the country since they would have required mechanics with electrical expertise. Likewise, 75 radial-diesel Sherman tanks were built, but none were shipped out so they could continue to supply just one fuel, 80 octane gasoline.

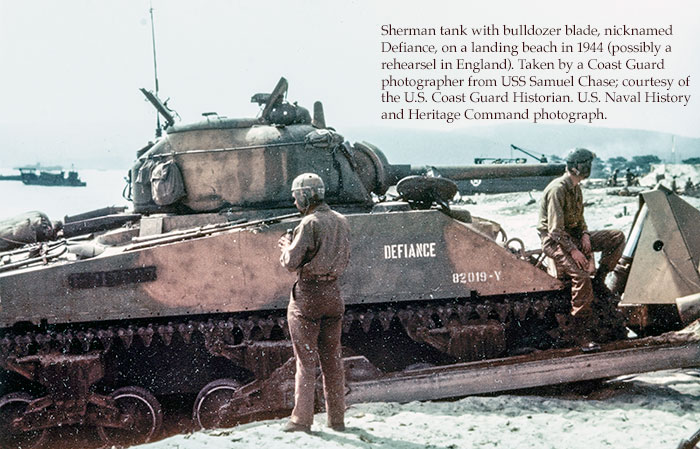

During the war, experience brought feedback and improvements, along with specialized variants; the “easy to assemble” Sherman was easy to modify as well, and the British, in particular, used it to build amphibious float tanks, bulldozers, platforms for artillery, and minesweepers.

The Sherman tank continued its service in the Korean and Vietnam Wars; in the 1965 Indo-Pakistani War; and fielded by Israel against Russian tanks in various wars. Indeed, by upgrading them, Israel kept the Sherman tank alive into the 1970s. After World War II, Israelis found junked Sherman tanks, brought them home, and repaired them, in some ironic cases using guns from German tanks. By 1948, they had 50 tanks; in the early 1950s, France sold them 60 surplus Shermans. France then supplied newer French-made M50 tanks; in one war, there were French Sherman tanks on both sides, some fielded by Egypt, some by Israel.

The M50, dubbed “Super Sherman,” used a long-barrel 75mm high-velocity cannon, which required numerous changes. They had either a gasoline engine or a Cummins diesel. Israel bought and used 100 of these, but then switched to the M51 “Isherman.” One reason was because Egypt and Syria were getting more sophisticated weapons from the Soviet Union. The United States started selling limited numbers of Pattons to Israel at the same time; but they were coming in slowly, and Israel needed more powerful tanks right away. The M51 had a low-recoil 105mm cannon with other modifications, with a 460 hp Cummins diesel and wider tracks. Israel altered 200 of its existing tanks into M51s, but when fighting Jordan—which had Pattons among other weapons—they were at least evenly matched and possibly overpowered. Most of the older “Super Sherman” tanks were retired or converted into howitzers, mortar carriers, rocket lauchers, observation vehicles, and ambulances, but the Ishermans still had a place, and served well during the 1973 Yom Kippur War. Sherman-based howitzers were used in the 1982 Lebanon war as well.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos