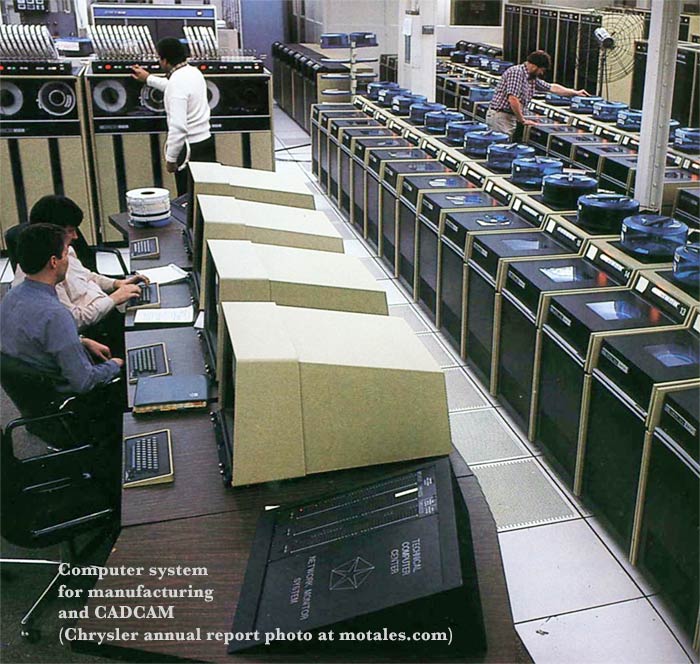

Chrysler was the first automaker to use computers in body design—using them to help in the transition from body-on-frame to unibody construction, and to design of the 1960 Valiant. They developed software internally and kept using it, largely for chassis development; and when people from their Huntsville aerospace group started migrating over to the automotive arena, they also used digital methods to improve aerodynamics for racing.

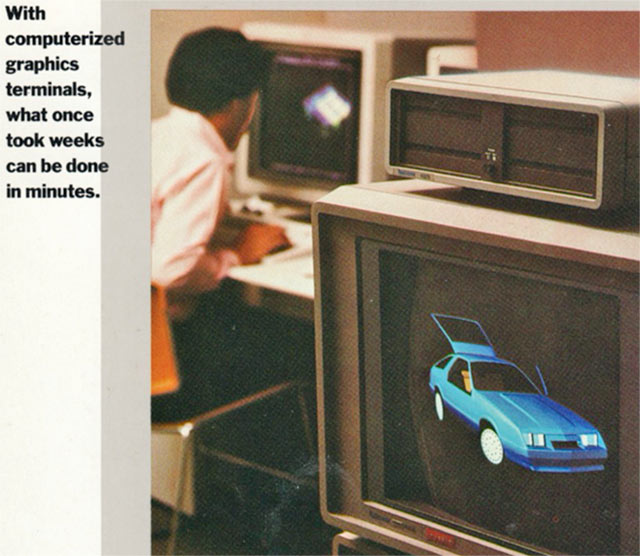

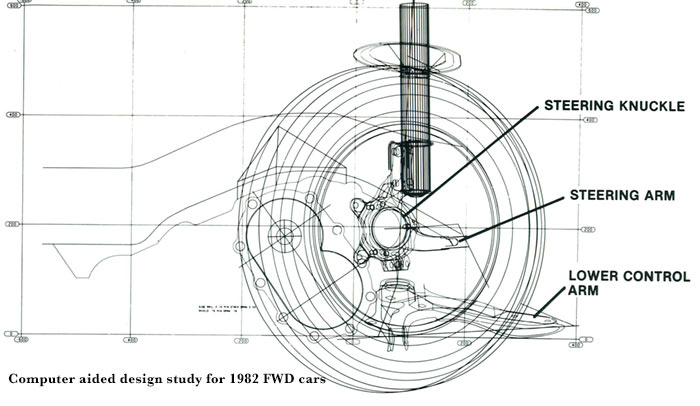

Chrysler’s CADCAM system was a major advance. Using computers rather than manually drafted images was both an economical boon and a gain in accuracy: manual drafting uses people to convert three-dimensional objects to two-dimensional images, and always had some guesswork. It was also slow; and errors happened despite great skill. Showing motion was difficult at best, and modeling wear on a part just wasn’t going to happen. This was especially true for projection of skewed views, which are not parallel to major drawing views (plan and front). Indeed, when Chrysler launched the Plymouth Scamp (L-body), they wrote that CADCAM had tripled productivity versus hand drawings.

CADCAM and other systems could also measure body stresses, make sure different parts did not interfere with each other, and account for build tolerances. Later systems could guide machinery to make parts—and, later still, 3D-print parts. The software can make sure parts fit together correctly, will survive hundreds of thousands of miles of driving, and allow for simulated assembly to avoid “oops, we can’t actually put this together” moments. Software can be used to create virtual cars and test them in simulations, so fewer mules and prototypes can be built, saving time and money. Finally, the software makes it easier to re-use parts and assemblies in other cars. But perhaps that’s getting ahead of ourselves.

Over time, the state of the art—and Chrysler’s demands—moved forward. One need they discovered was to handle wear in cutting tools and such; as time goes on, stampings and cutting tools wore and parts dimensions would change ever so slightly. This had to be taken into account, and CADCAM did not do that.

What’s more, while CADCAM let engineers develop and manipulate objects on screen, they were based on wire-frames; they could not accurately represent a true surface, because the space between the wire-frame lines were not mapped out. Newer software could fill in the space between the graphed lines. This was a problem: as Frank Havasi, manager of the Neon Body-in-White program, said, “it was possible to take a design from computer to a clay model and discover that the surface was not linear.”

At Lee Iacocca’s command, around a dozen design engineers were conscripted to be trained in other programs than the ones they knew, and then to compare them all. The project reported to the Technical Computer Center, which was part of Engineering rather than IT. A fictional pilot program was created, to be carried out in each software package. The criteria for judging the packages were:

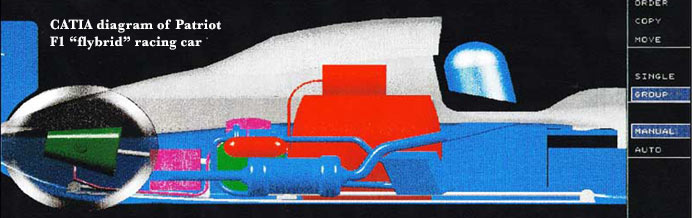

Chrysler’s CADCAM was one of the candidates, along with GM and Ford’s systems, Dassault’s CATIA, SDR-C I-DEAS, and Pro Engineer. CATIA had a major advantage: while it was developed by an aviation company, it had been adopted by AMC, which was now owned by Chrysler Corporation. That meant the company had a group who would not need retraining, and could in fact help to train Chrysler people. (CADCAM was supported by the internal UNIX and mainframe groups, and would have been developed further to meet future needs.)

Chrysler spent around $2 billion to change from their internal CADCAM setup to CATIA. Along the way, to avoid having negative numbers in any of their plans, they moved their reference point forward by a meter. The change also took five years, moving all processes and products forward. Since the LH car was already in development when the process was started, the second “new Chrysler” vehicle—the 1994 Dodge Ram 1500—was the first to be entirely drawn up in CATIA.

An advantage of storing the car design by numbers, with a computer model and all specifications in a database, was that the information was available not only to every engineer on the program, but also to suppliers who provided parts and tooling. No paper had to be moved around, and a great deal of guesswork was eliminated. That also made life much easier for manufacturing; major problems were prevented, and minor ones were caught earlier.

The Dodge Viper was an interesting mix: because it was a rush project, and some engineers knew CATIA while others knew CADCAM, it was developed in both programs, with some parts in CATIA and others in CADCAM. Eventually it was converted entirely to CATIA.

As the new software was put into place, engineering processes and systems were changed to maximize CATIA’s strengths and abilities. This put Chrysler far in advance of just about any automaker in the world in speed and cost of development; both process and computer changes were a competitive advantage. As the 1990s progressed, Chrysler racked up awards and had above-average conquests from competitors and customer loyalty alike. It was a very different position from Chrysler of the early 1970s. One way the software made it possible was tighter supplier relationships (and SCORE), where suppliers could save Chrysler money by helping to redesign parts using their deeper technical knowledge.

Development of the 1995 Neon was sped up a bit by having computer-based tooling cut carbon fiber body panels, to make the first body prototypes more quickly than they could be done by hand. Body panels would normally not be ready that early; engineers working on parts that had to interact the body would only be able to see renderings and blueprints, and could not check for problems until late in the process.

That was possible partly because CATIA not only mapped out complete surfaces, but even provided simulated light reflections to let engineers and designers “see” the surfaces as though they were real. Frank Havasi of the Neon program said, “That’s a far cry from when our designers would take a wood model, which was developed from a clay model, and eye the surface for imperfections—using a piece of sandpaper to smooth out the flows.” That wood model was the basis of tooling for steel-and-plastic-bodied cars.

Havasi added that the Neon was the first program at Chrysler to have no tooling crashes—that is, no sudden reworking of tooling at the last minute, an expensive process requiring overtime and extra fees to outside companies. “Imagine getting through clay models, wood models, tooling blue prints, and eventually hard tooling, only to find there is a flaw in the tooling which mandates starting all over again.” Havasi said that didn’t happen with the Neon.

The system also allowed testing of the pilot plant early on, so that problems were spotted before the actual plant was tooled and readied. At the point where, in a normal program, the first steel panels would be stamped for prototypes, in the Neon program, they were using CATIA-cut carbon fiber to check the hard tooling.

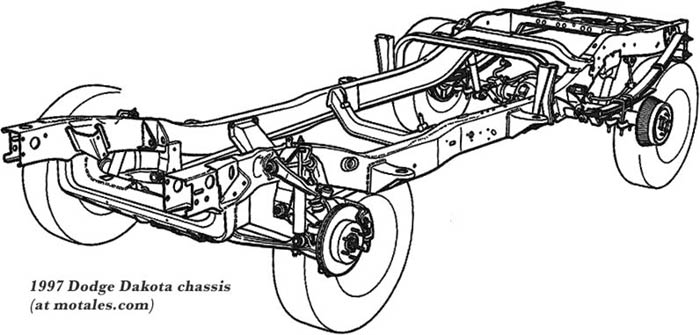

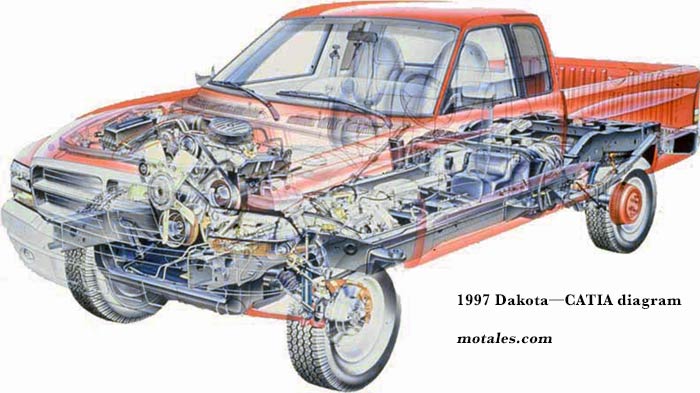

Another example was the creation of the new 1997 Dodge Dakota; they used CATIA diagrams of the existing Dodge Ram 1500 pickup, and were able to use the same production line and some processes for both. The size of the components was different, but they could be put together the same way. Using the same architecture enabled Chrysler to create and tool the Dakota in 30 months at a cost of less than $500 million—cutting the development time and cost dramatically from the way it would have been done before. Frank Ewasyshyn, then vice president of advance manufacturing engineering, said they essentially used the Ram cab’s construction methods and structure and resized it to fit the Dakota’s needs.

One advantage of using CATIA was being able to do a full assembly plant in software before making a single tool; virtual versions of the Dodge Dakota plant and then the Jeep Liberty plant in Toledo allowed for 600 experiments, with both product and people visible within the system, for 21 miles of conveyor. They simulated over five thousand days of production.

Reader R.B. was just watching a Siemens PLM video on their “Simcenter 3D” integrated suite of simulation/analysis software packages. At around 13:25 in, they briefly showd an image of the original Neon! (The annotations in orange are R.B.’s.)

The Neon was designed using Catia; but SDRC’s I-DEAS CAD and analysis software was considered to be the best for structural analysis back then, so the company may have exported the Catia unibody design into I-DEAS (or NASTRAN, or the like). Siemens bought and integrated SDRC’s I-DEAS into Unigraphics, then merged them into today's NX CAD; Simcenter 3D also incorporates NASTRAN. That may explain the image of the original Neon showed up in this brand-new Siemens Simcenter 2023 video (although the CAD was done in Catia, the analysis may have been done in either I-DEAS or NASTRAN).

In 2003, Nissan and Ford used IDEAS (but Ford was moving to CATIA); GM used Unigraphics; and Toyota, Honda, Porsche, PSA, Volkswagen, Volvo, and Land Rover used CATIA. Dassault had became the largest supplier of CAD/CAM and PLM software, with both automotive and aviation buyers; some claimed they started becoming arrogant, and that CATIA v5 was unstable. Siemens bought Unigraphics (UG) and made it the basis of their own NX software. Former engineer and member of the Chrysler software evaluation team Robert W. Sheaves wrote that NX was easier to run, but it didn’t work with any other system, and had less precision in the data used for wear calculations and manufacturing (11 digits vs 19 for CATIA).

When Fiat acquired Chrysler, it moved the latter over to NX. There were two rationales: lower prices and an assumption that Chrysler would be moving to Fiat designs. Daimler also, coincidentally, moved to NX at about this time, while Peugeot was using CATIA. This raises questions about Stellantis moving forward; it appears that STLA Large is a new projects using Chrysler’s work as a starting point, while STLA Small and Medium are both clearly Peugeot-based. This suggests standardizing on Peugeot’s software eventually; only STLA Frame and legacy products are questions.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos