The Chrysler plant is on Route 20 in Belvidere, Illinois, quite close to Route 90 near Rockford, and not too far from Chicago; it started making cars in 1965 with full-sized Plymouths and Dodges. The factory is named after the town; it never made Plymouth Belvederes, which were named after a hotel.

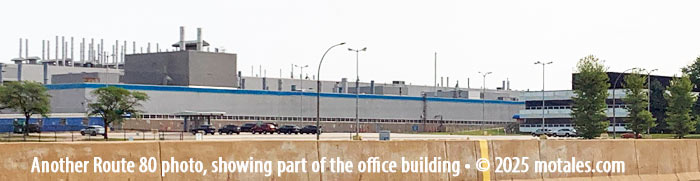

The office building is quite modern looking and distinctive, with an appearance unique among Chrysler facilities. The Belvidere factory buildings themselves look similar to most GM and Ford plants.

In 1977, Belvidere Assembly (and its associated, marked stamping plant) started making the Horizon, Omni, O24, TC3, Charger, Turismo, and Duster. Peugeot engines were brought in from France, “dressed” with a carburetor and accessories, and installed; the Omni and Horizon were engineered mainly in France (with American independent front suspensions) and styled in England; the coupe versions were American adaptations.

The signs have been changed from their original Chrysler to DaimlerChrysler, then to Fiat Chrysler. So far there aren’t Stellantis signs at the factory.

After making the company’s cheapest cars, Belvidere switched to the top of the line Chryslers: Imperial, Fifth Avenue, New Yorker, and Dodge Dynasty. In 1992, this took 3,250 hourly and 250 salaried employees; they were on average 48 years old, with an average of 23 years at the company. The combined payroll was $231 million, and they made 125,000 cars, so factory labor was around $1,848 per car (not counting parts). Labor costs were likely somewhat high as these were the company’s most expensive, nicely outfitted sedans.

In late 1993, the plant had 5.9 million cars under its belt. Now, it switched back to the least expensive cars Chrysler had—Plymouth and Dodge Neons. Employees were part of a 90-day, million mile Neon quality program starting in September 1993; a hundred assembly workers drove 50 cars every day, in eight-hour shifts, over different roads, trying to put at least 12,000 miles on most of the cars, up to 36,000 miles on as many as possible and 100,000 miles on at least two of them, to find what would fail. The factory had 3.3 million square feet of floor space covering 280 acres, not counting the separate office building. A satellite plant made fascias; it was designed and supported to Textron.

The following chart shows U.S. Neon sales, and Belvidere Neon production by calendar year. There were two plants making Neons, the other in Mexico; the car was sold around the world, and was popular in Canada, where it was also sold as the SX 2.0. We do not have access to other sales figures. Most numbers are from Ward’s Automotive. Chrysler production figures before 2003 are unknown (Neon was a Chrysler outside North America and, in some years, in Canada).

| Neon: Belvidere | U.S. Sales | |||||

|---|---|---|---|---|---|---|

| Dodge | Plymouth | Chry. | Dodge | Plymouth | ||

| 1993 | 2,754 | 1,522 | 0 | 0 | ||

| 1994 | 125,811 | 117,011 | ? | 93,300 |

85,660 | |

| 1995 | 130,887 | 116,592 | ? | 133,984 | 106,205 | |

| 1996 | 131,343 | 103,813 | ? | 139,831 | 105,472 | |

| 1997 | 115,110 | 82,881 | ? | 121,854 | 86,798 | |

| 1998 | 129,875 | 87,066 | ? | 117,964 | 78,533 | |

| 1999 | 165,229 | 66,905 | ? | 112,236 | 71,561 | |

| 2000 | 179,039 | 49,623 | ? | 113,381 | 49,951 | |

| 2001 | 145,718 | 10,756 | ? | 107,299 | 30,054 | |

| 2002 | 156,988 | ? | 126,118 | 605 | ||

| 2003 | 150,957 | 1,859 | 120,101 | |||

| 2004 | 139,004 | 1,844 | 113,476 | |||

| 2005 | ? | 113,332 | ||||

| 2006 | 17,239 | |||||

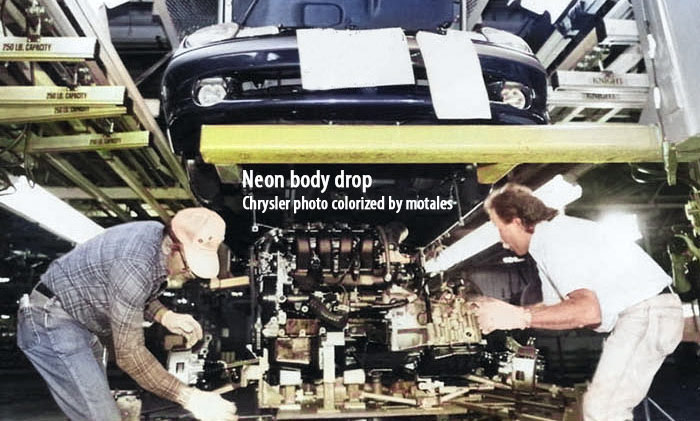

The company set up a test line so manufacturing engineers could test ergonomics and technical issues in advance, at a much lower cost than planning it out on computer models, building, and then moving things around as needed (later, Chrysler had better computer models and could do all initial work online).

1993, above. 2025 pentastar closeup, below.

Manufacturing, engineering, and procurement people visited suppliers to make sure they were ready to launch. A materials management work team was set up; they replaced cardboard boxes for parts with plastic containers that were sent back to suppliers and re-used. Between this and other measures, they eliminated 95% of waste materials, saving a great deal of money and also reducing damage to parts in transit. They were ready for serious Neon production to begin—which it did on November 10, 1993, with 380 robots and 3,480 people. They made around 1,064 Neons per day, and Toluca (Mexico) made more.

The stamping plant added a new $45 million Verson press in late 1997, the largest built in the United States—the size of 12 locomotives. It was first used for making doors. In summer 1997, the body shop added a $45 million powder anti-chip paint system. This required a 72,000 square foot addition. The process and water-borne base coat system already used made Belvidere one of the most environmentally-friendly automobile plants in the nation, at the time, slashing VOC (volatile organic compounds) emissions and waste.

Those eventually gave way to the Caliber, Compass, and Patriot triplets, all built on the same assembly line after an upgrade which included a robotic body shop that could build the Dodge Caliber SRT4, Caliber, Compass, Patriot, and one other vehicle without loss of speed; robots made tool changes within normal 45-second cycle times. By this time (2005), the plant had 3.7 million square feet of space and just 1,700 employees. The first post-Neon car was the 2007 Jeep Patriot, made on December 20, 2006.

Head of manufacturing Frank Ewashyshyn said the cost of adapting the plant to make all three of the triplets was less than the cost of adapting the plant to make just the Neon. That’s partly because new methods of making stamping dies saved up to 60% of the cost; inbound parts sequencing center (originally operated by TDS/US) managed more than 1,799 different parts, providing parts metering, kitting, and container management, and delivering complete subassemblies to the manufacturing floor as they were needed (it was later run by Syncreon). A tunnel connected the 500,000 square-foot sequencing center to the assembly plant, in kits, cutting costs by around 12% per year and helping with quality by creating a poka-yoke.

Making the Dart, Patriot, and Compass on the same assembly line at the Belvidere plant, in 2012

Next came the Dodge Dart, along with another 1,800 employees for a third shift—it was expected to be a major seller. The first car came on May 7, 2012, on the same line sthat made the Compass and Patriot. A new body shop had cost nearly $700 million, including equipment to handle the Dart. Sergio Marchionne, at an opening event, said, “It is no secret that this plant has always been one of the best assembly plants within Chrysler for performance, for productivity, and it is a benchmark which is now being measured against the European plants of Fiat. Belvidere continues to shine among the top performers of the whole group... Harbour measured the competitiveness of 34 plants across Europe and North America... not just within the Fiat Chrysler world, but [including] competitors; and Belvidere ranked third out of 34.”

Finally, the Dart was replaced at Belvidere by its platform-mate, the Jeep Cherokee. Since the Dart had been made on the same assembly line as the Patriot and Compass, it’s unclear why the Dart was dropped at all, rather than supplemented; but the Chrysler 200, made at yet another factory (Sterling Heights), was also dropped, almost as though nobody knew more than one car could be made on the same line. The stated rationale was that the Cherokee was the new hotness, and sedans were dead; but had they kept the 200 and Dart, or at least the Dart, sales pressure on the Cherokee would have been lower, and the plant could have been kept running at capacity.

In 2023 the Cherokee was dropped; its replacement was not to arrive until mid-2025, and that was to be made in Mexico. The factory was to be converted into warehouse space, but the union negotiated to get new product—a midsized pickup, due in 2027 (later postponed by Stellantis until 2028, after the end of the contract, suggesting the ability to close the plant then). The pickup does seem to be in the works, though, under a new Stellantis leader, and a few workers appear to have been at the factory, readying it for whatever comes next.

Looking at the nearly-empty factory from the highway, it is quite huge, but has no real identification—at night, large FCA signs may light up, but the modern “BELVIDERE ASSEMBLY” on the office building is mostly hidden by trees, the Cherokees have been removed from next to their rock piles by the chromed pentastar, and there is simply no large sign. Ford and General Motors show pride in their buildings; you have no doubt when you’re near a GM or Ford factory. Chrysler, on the other hands, seems almost ashamed of theirs, at times. The Toledo plant has a huge Jeep sculpture—but its sign is relatively small, and proclaims “Stellantis.” The large sequencing plant across the street has no signs or labels at all.

Part of the welcome awning seems to have been torn off. It’s hard to judge the age of the signs, which cover different eras, showing pentastars, Chrysler, FCA, and DaimlerChrysler—so far, not Stellantis, though the Jeep Toledo plant has a large Stellantis sign.

| Plymouth, Dodge | 1965-73 |

| Chrysler, Plymouth, Dodge | 1973-77 |

| Horizon / Omni | 1977-87 |

| L-based Charger, Duster, etc | 1979-87 |

| Dynasty, New Yorker, Imperial, Fifth Avenue | 1988-93 |

| Neon | 1993-05 |

| Caliber, Compass, Patriot | 2006-13 |

| Cherokee | 2013-23 |

| New pickup? | 2027ish |

Dates on the table may not be completely accurate past 2000, and are calendar rather than model years.

While the next product for Belvidere is supposed to be a midsized pickup, plans at Stellantis can and do change, and import taxes may force some other vehicle there first. Only time will tell; Stellantis is unlikely to give much away for a while.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos