In the 1980s I was an engineering student at the University of Detroit. This was a co-op program, so as part of my curriculum, I got a job at Chrysler as a Supplier Quality Assurance Specialist in the Powertrain Components Group of the Supplier Quality Department. I surveyed suppliers to ensure consistent quality in parts that bolted onto the engine: fuel injectors, exhaust, gas tanks, and many tubes, pipes, hoses, and grommets.

At this time, around two-thirds of the car parts were outsourced, while Chrysler made about one-third. To ensure quality, we provided clear and specific specifications and drawings to the suppliers.

Drawings had critical elements called out with one of three shapes: a shield for government regulations. a diamond for important dimension needed for parts to work properly, or a Pentastar for industry standards such as SAE, AISI, or internal Chrysler standards.

Parts could be black box, in-house design, or outside design and developed (ODD Box). Black box parts were pre-designed (purchased “off the shelf”), like spark plugs. Chrysler Engineering designed some parts but the manufacturing was outsourced. ODD Box used a supplier’s expertise to both design and make a part. Suppliers bid on the parts through the Purchasing Department. The Supplier Quality Department then made sure the parts were technically correct and conformed to the required specifications.

Once the part type was set, engineers conducted a FMEA (Failure Mode and Effect Analysis) to ensure quality. The manual (shown below) detailed how to analyze the part’s design and potential failures, considering factors like minor inconveniences, reduced performance, cosmetic issues, or more severe problems like braking system failure or the car stalling. What’s the impact of that failure, and how can we minimize it to prevent future failures?

Measuring the success of a part is crucial, but it’s not just about aesthetics or performance. We need a scientific approach to develop measurable metrics.

Design of experiments using the Taguchi method provides a scientific approach to developing tolerances and specifications. This information is then provided to suppliers, who could start making the parts.

Now, we can focus on maintaining quality from external suppliers and the requirements they must meet.

Quality is often subjective, but it can be defined as meeting specific requirements. If an item meets all requirements, it’s considered high quality; if it doesn’t meet the requirements, it’s low quality.

We used statistical process control (SPC) to measure quality. As a young engineer, I diligently worked on the task, but one of the older engineers, who was smoking a cigar (which was allowed then), interrupted me. He asked me what I was doing, and I explained the boss’s request. “Pete, what are you doing? You’re calculating wrong.”

I said no, but he insisted, “If you know statistics, you’re doing it wrong.”

Statistics is integral calculus, and that’s what I was doing. He brought back a formula card with everything laid out and said, “Just make the calculation. Nobody cares how you got it, as long as it’s correct. If you’re using calculus, you’re doing it wrong.”

I’ve been an engineer for 35 years and haven’t used calculus again. I’ve gotten along fine.

Early on, we learned about range and attribute charts, and CPK index. The CPK index measured the manufacturing process’s capability to make sure the process was repeatable, reliable, and consistent and that the specifications were within a certain range and certain attributes were met.

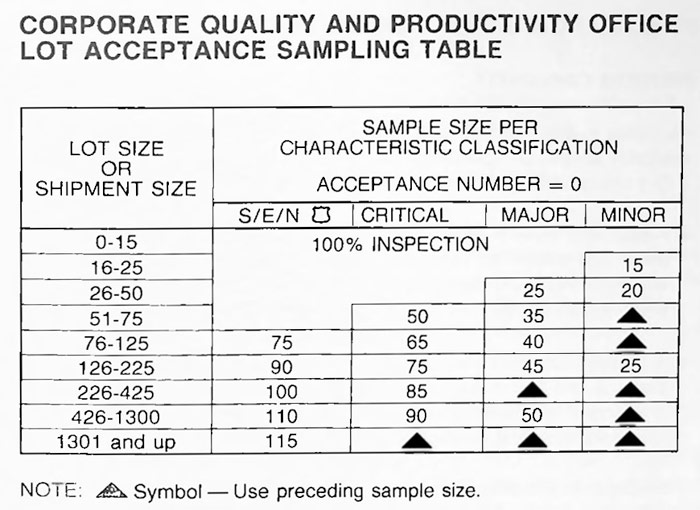

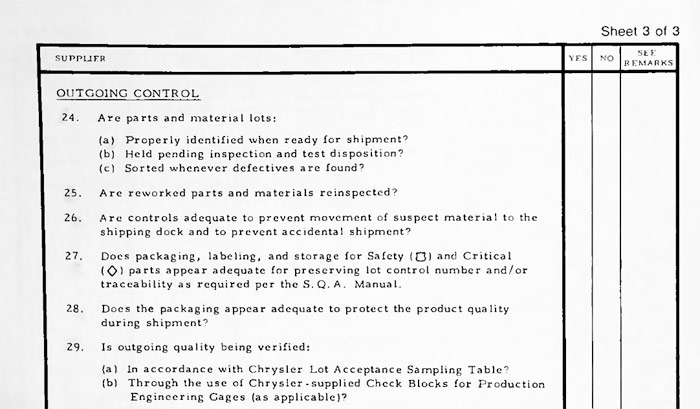

We relied on our suppliers to get quality parts, and provided them with a manual defining what Chrysler expected from its suppliers, provided accepted analytical methods, record keeping, drawing and change control, and lot control and traceability. We did a survey every year to ensure the supplier was meeting the quality requirements.

I used to go out to the supplier plants and review the work and records. We met with suppliers around the world to ensure compliance with the requirements and to evaluate areas for improvement.

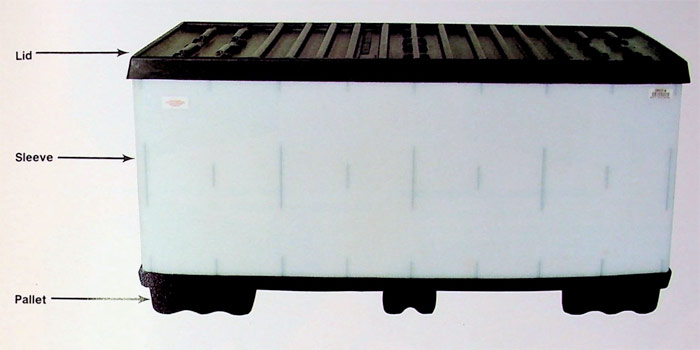

Suppliers couldn’t just throw parts in a box and ship them; Chrysler published a manual with their requirements, which detailed how parts were to be packed and shipped efficiently and economically.

When shipping parts, it’s important to minimize damage. Trucks are loaded so that the heaviest parts are on the bottom and the lightest parts are on the top, similar to loading a grocery cart.

Standardized packaging was crucial because automatic guided vehicles (AGVs) in the plants could only accept certain sizes of boxes or containers. It was important to pack parts the same way repeatedly in the same type of packaging so that the AGVs could deliver them to the proper places on the assembly line.

From an economic perspective, reusable containers, racks, pallets, bins, and boxes were encouraged. This way, they could be returned to the supplier and reused instead of being disposed of. Boxes may be designed to be stackable. Collapsible or easily returnable to the supplier for reuse, corrugated boxes must meet standards to prevent collapse during unloading and movement.

Proper loading of trucks maximizes economies and efficiencies, especially with the rise of just-in-time delivery and manufacturing.

To ensure timely arrival at the assembly plant and avoid production delays, parts must be easily identifiable. Chrysler developed shipping parts identification label standards, defining label size, placement, and content, including part number, lot number, and box location. This consistency enhances efficiency and allows quick identification by workers.

Barcode standards helped with quick identification within the plant. With just-in-time delivery and manufacturing, consistent packaging and identification are crucial for efficiency and cost-effectiveness.

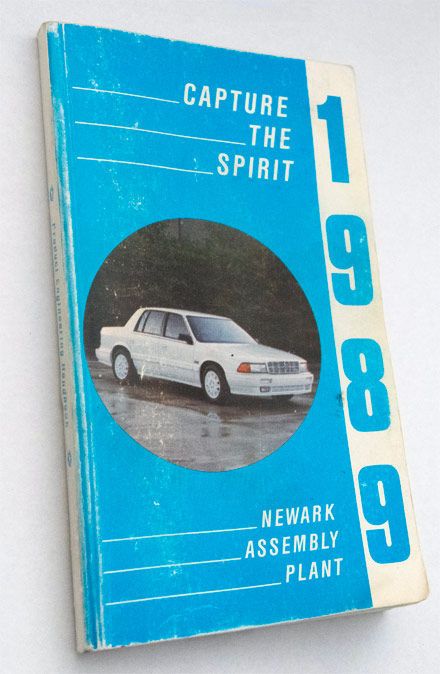

I worked on the AA body launch for the 1989 Dodge Spirit and Plymouth Acclaim at the Newark (Delaware) plant, which is now part of the University of Delaware.

As part of supplier quality, my responsibility was to ensure the correct delivery and quality of parts from our suppliers to the plant. I walked the line daily, inspecting parts, checking for proper labeling, and addressing any issues. We collaborated with suppliers to resolve problems.

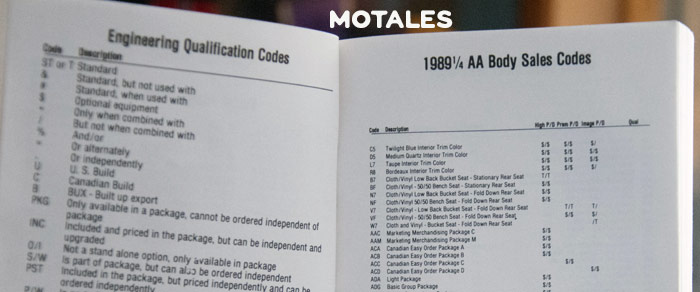

Navigating the assembly plant was challenging, but the Project Engineering Handbook pictured below provided essential information for the AA cars. It included sales codes, packages, vehicle identification plates, parts lists, assembly information, and tolerances. This allowed us to reference the handbook when visiting the body shop and ensure that parts were in the correct place and assembled correctly, as much of the process was automated with robotic welding.

At the beginning, we counted the number of welds to ensure everything was good for the initial startup of the AA body. This was interesting because there were a few things to sort out along the way. We also looked at the wiring harnesses and connectors, as cars were becoming more complex. We had to ensure the right harnesses and connectors were delivered for proper assembly.

We also checked the wheels and wheel covers’ alignment settings, as the wheels needed to be aligned after the cars came off the line. The most important thing was paint codes and color compatibility to avoid mismatches. We ensured that all pre-painted parts’ paint matched the cars coming down the line for consistent colors.

Once the cars were complete, they underwent a separate quality inspection by a different group. Then, they were prepared for transport to different dealerships across the country.

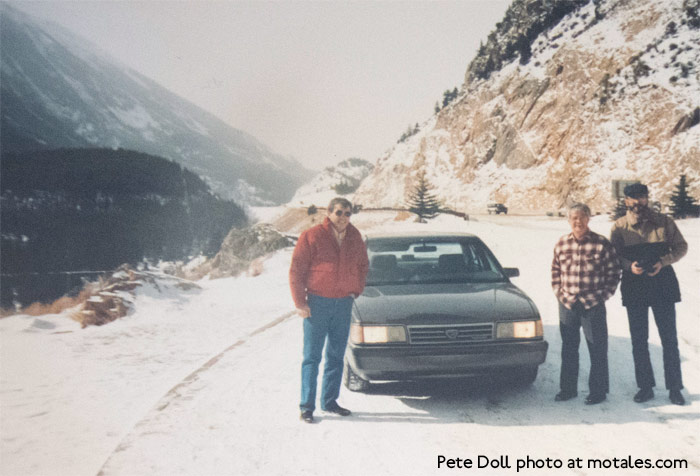

In 1987, Chrysler purchased American Motors and as part of that deal the Renault Premier (to become the Eagle Premier and Dodge Monaco under Chrysler) came along. Chrysler was very interested in the Premier, and, contrary to popular belief, it was one of the main reasons why Chrysler purchased American Motors. They needed a new large car platform, and the Premier fit the bill.

At this time, Chrysler had a quality testing program called Lap of America, and that’s exactly what it was. Cars would come off the line, and engineers would drive them across the country for two weeks of testing and evaluation. We needed to take the Premier across the country to make sure it was a quality product; again, Chrysler needed a new large car platform, and buying AMC was likely not much more expensive than developing one in-house. The Premier led directly to the highly successful LH—the Intrepid, Vision, Concorde, LHS, 300M, and New Yorker. The Eagle Premiere was powered by either the 3.0L PVR V6 engine or the 2.5 l4 AMC engine; both were longitudinally mounted even though they were front wheel drive, in the French tradition. This design allowed for potential future all-wheel drive versions, and the LH and later LX cars kept it.

For our trip we took four cars across the country. Two of them had the V6 and two had the 2.5 four-cylinder. We had a crew of eight engineers and mechanics—one each from the Engine and Transmission departments, an engineer from Kenosha Engine, a mechanic from a Dodge dealership, engineers that dealt with plastics, audio systems, and such so that there could be a complete evaluation of the car. I represented the Supplier Quality Assurance Department.

The trip started out in Detroit; we drove through the northern part of Michigan, the Upper Peninsula (eh!), over through Wisconsin, up to International Falls, Minnesota. This trip took place in January, an ideal time to do cold start testing in International Falls. Being the youngest guy on the crew, the job of starting the cars early in the morning fell to me—at 5:00 in the morning, I had to wander out to the parking lot and see how long it took to start the cars and how long it took them to come up to temperature. That was fine by me as it was a good learning experience.

Other things we looked at during the trip were fuel economy, performance, comfort, and how different things functioned. It was an overall evaluation of the car, not looking at anything specific.

From International Falls we then went on to Dickenson (North Dakota), down to Buffalo (Wyoming), Denver (Colorado), Santa Fe (New Mexico), and concluded in Phoenix (Arizona)—for us. We flew back and eight other people took the cars back to Detroit on a southerly trip, completing the Lap of America.

This testing was not unique for the Eagle Premier. Friends of mine did the Lap of America for the Jeep Wrangler, and then for the 1989 Dodge Spirit and Plymouth Acclaim. It was an ongoing process, part of Chrysler’s Continuous Improvement Program, and it was a good way to get a feel for these cars and how they would respond on long trips in the real world.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky