Chrysler’s first truly new V6, launched for 1990, used pushrods and two valves per cylinder to keep costs low and simplify manufacturing. It had distributorless ignition and was reliable, if unexciting, with up to 150 hp at launch. That didn’t satisfy the new head of engineering, Francois Castaing.

Castaing, who also pushed for the 4.7 V8 and Hemi, demanded a new V6 with four valves per cylinder and overhead cams. He started the project in early 1989, even before the 3.3 started production, to have it ready for the upcoming “LH” big cars just 40 months later.

Castaing himself wrote that “the team knew they had never designed a new engine that quickly (40 months). Also, the investment would be quite high. There also was the fear that when you commit a lot of money for the company, you want to commit it right and not make a mistake. Still, ... instead of giving in to the negatives that it couldn't be done, that we couldn’t get the technology, the slickness, the power, the low emissions, the fellows said, ‘let’s go for it.’”

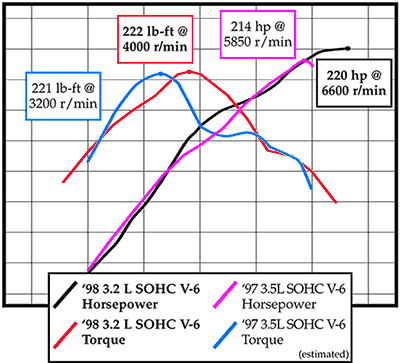

Burke Brown, on the powertrain team, later said, “Francois [Castaing] was from the European culture, so his idea was getting a lot of power out of a small displacement engine that would naturally get you a little bit better fuel economy. ... you have to worry about the low and mid-range power. The 3.5 had that big, long ram manifold on it with the two frontal bodies. That’s exactly what we were doing there. We were getting a nice, midrange torque out of it. Being a four-valve engine, if you revved it up it had good top-end and it was only 3.5 liters and it was making 214 horsepower. It was 215 cubic inches, and I remember saying if we hit 215, we can say ‘one horsepower per cubic inch,’ but it didn’t quite make it. The later engine did 250 horses.

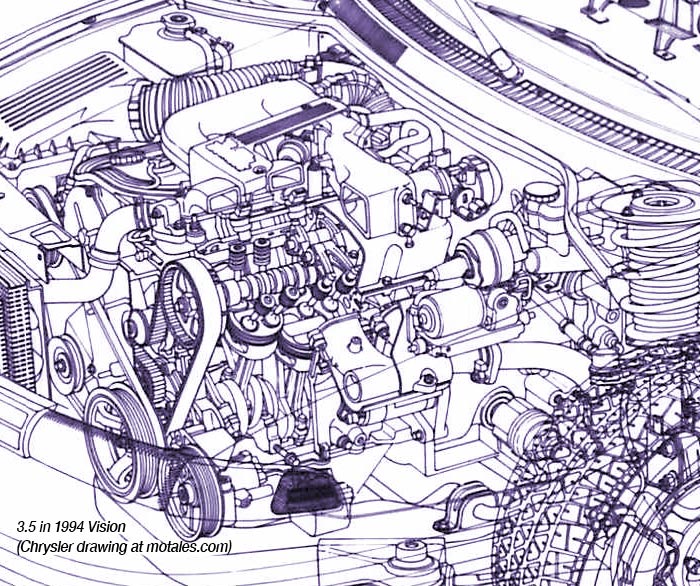

With Gordon Rinschler in charge, the 3.5 quickly took form, using a deep-skirt cast iron block, forged steel crank, and 10.4:1 compression ratio. To make it small enough to fit into the sleek LH cars, the 3.5 was first high-volume engine with bottom-feed fuel injectors, using sequential injection. Spark plugs were in the center of the combustion chamber, a semi-Hemi style, with generously sized 35mm intake valves and 29mm exhaust valves.

The engine had just a single cam in each head, but John Hurst created a dual valve rocker arm shaft system to use four valves per cylinder. The valvegear was non-interference (free wheeling), so the pistons would not hit the valves even if the belt broke.

Instead of a distributor, the engine used three coil packs, each of which fired two plugs at once (one unnecessary fire, one ignition fire) to save the cost of having twice as many coil packs.

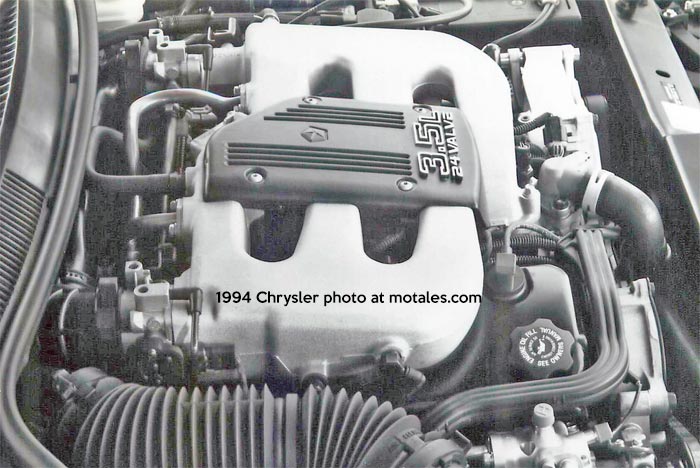

The shape of the 3.5—roughly a square, with a distinctive flat-topped air intake system—made it quite distinctive among Chrysler V6 engines.

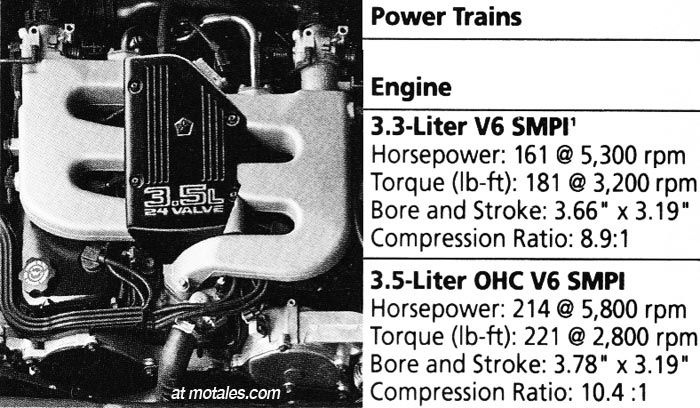

The new engine had one part in common with the 3.3—the oil pan; but to save time and money, they shared bore spacing and main journal and crank pin diameters. The 3.5 required midgrade (89 octane) fuel, while the 3.3 took regular (87 octane), but the difference in horsepower was immense: from a mere 0.2 liters, the new engine delivered another 53 hp and 40 lb-ft of torque. Its main benchmark, overall, was Acura’s 3.2 liter V6.

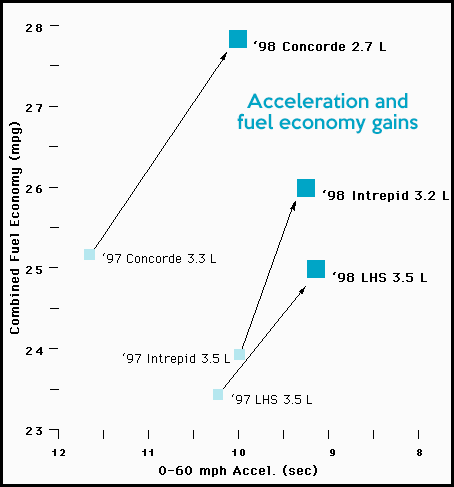

The new 3.5 liter engine debuted in the 1993 Eagle Vision and Chrysler LHS with 214 horsepower and 221 pound-feet of torque, beating most other engines in the class above those cars. It made for a pleasant driving experience, with good torque and reasonable economy; the 3.5 was quite powerful for the time and yet durable and generally trouble-free. The engine was unchanged until a substantial power boost in the 1999 models—but it also spawned a direct spinoff, the 3.2.

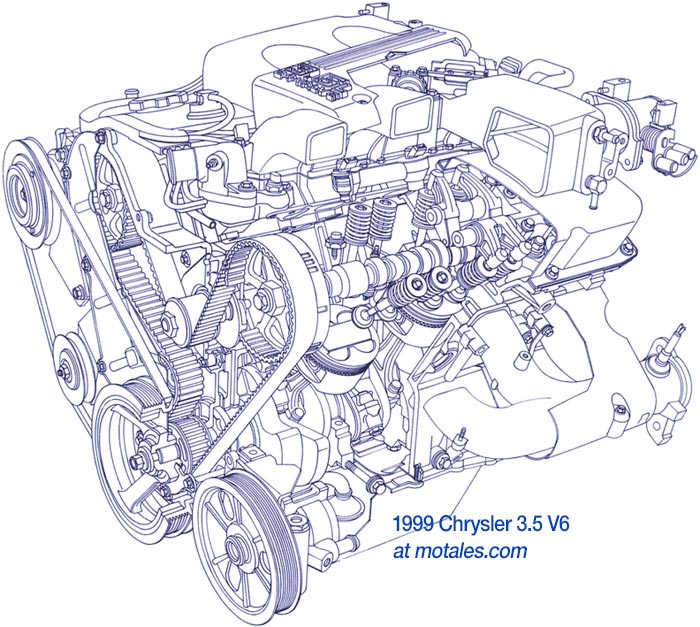

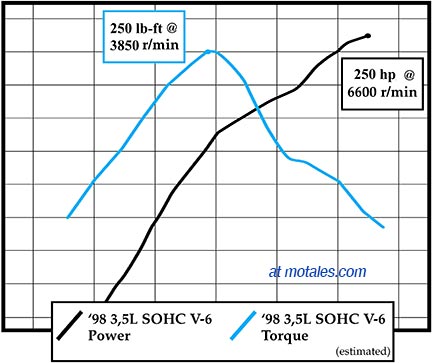

The second-generation 3.5 came in 1999, bringing output to 250 horsepower; it was unusually quiet due to a variety of noise-reduction changes as befit its place as an engine for premium cars. It still took midgrade (89 octane) fuel and kept the single cam. Burke Brown, head of the LH engine program, said it was quite similar to Mercedes’ own 3.5 liter engine, except that Chrysler used semi-permanent molds with cast-in iron cylinder liners; and Mercedes had no liners, but were hardening the aluminum, in a very expensive process.

Burke continued,

“We had a perfectly round iron bore, unlike a cast iron block, where the water jacket isn’t always the same thickness, so the water cooling for the cylinder isn’t as perfect as we could get it because everything was just the same. ... ours was bulletproof. To this day, I've never heard anybody talk about an aluminum engine that’s had a liner come loose or leak or anything like that. Never.”

The Chrysler 3.5 engine, while costing far less to make, produced better horsepower and torque than the Mercedes E320 V6, along with the I-6 in the BMW M3, the V8 in the Ford Taurus SHO, or the V6 in the Lexus GS300.

Development time was cut by 26 weeks by using software-based modeling and prototyping, resulting in the industry's first “paperless” engine.

| Car | Engine | HP | Octane | Car $ |

|---|---|---|---|---|

| 1993-97 Chrysler LH | 3.5 | 214 | Mid-Grade | $24,270 |

| 1998 Chrysler LH | 3.2 | 220 | Regular | $24,000 |

| 1996 Taurus SHO | 3.4 | 235 | Premium | $28,250 |

| 1998 Chrysler 300M | 3.5 | 250 | Mid-Grade | $30,000 |

The new 1999 version did not just beat most competitors in power; the Acura, Catera, and Diamante all required premium (91 or 93 octane) fuel while the 3.5 took midgrade. It now had an aluminum block rather than an iron block, cutting weight. Power ratings were 232 hp for midsize cars with restricted air parths; most of the time, 250 hp in big cars; and 253 hp in the Chrysler 300M Special. Gas mileage also increased by around 10%, and the engine met the California Low Emission Vehicle standards in 2000.

Changes to cut noise included a new structural oil plan; select-fit main bearings to minimize clearance; computerized flow guided antifreeze passages in the block; new dual hydroelastic engine mounts; revised alternators; and a new air induction system including a Helmholtz resonator on the inlet air duct and an inline resonator. The induction system was clearly different from the first generation but the engine kept its basic shape and unique look.

The block had 11% more torsional stiffness thanks to ribbing, six bolt main bearing caps (rather than four), preventing crankshaft deflection; and a structural beam windage tray, which also supported the main bearing caps. The pistons were 15% lighter and the rotating parts were better balanced. Cast aluminum head covers were completely isolated. New accessory drive mounting brackets were stiffer to prevent vibrations.

Power gains largely came from higher intake flow: a larger throttle body, higher-flow intake ports, larger intake valves, higher valve lift, and a composite (plastic) manifold which provided smoother surfaces than cast aluminum—a setup pioneered on the 1995 Neon. Airflow was optimized by computer. The high output version had a three-plenum intake manifold (normal versions had two plenums), with a manifold tuning valve to vary the length of the intake manifold tubes and create supercharging effects at different engine speeds.

In the first generation, cylinder bank had its own intake manifold and throttle body. This was replaced in the new version by a single throttle body with multiple plenums.

| 1990-97 | 1999 | |

|---|---|---|

| Compression | 10.44:1 | 9.9 or 10.1:1 |

| HP @ rpm | 214 @ 5,800 | 250 hp @ 6400 |

| Lb-ft @ rpm | 221 @ 2,800 | 250 lb-ft @ 3900 |

| Valves | SOHC, 24 | SOHC, 24 |

Blocks were heat-treated. Crankshafts were still forged. Oil drain passages were cast into the block for faster circulation under severe high-speed conditions. Ignition was now a coil on plug setup with six coils and 100,000 mile spark plugs. Knock detectors were phased in to allow more aggressive timing with protection against bad gas.

The 3.5 liter V6 engine finished production in 2010, still making 250 horsepower; it was the standard powerplant in the Dodge Charger, Dodge Challenger, and Chrysler 300, and was only replaced by the competely new Pentastar V6.

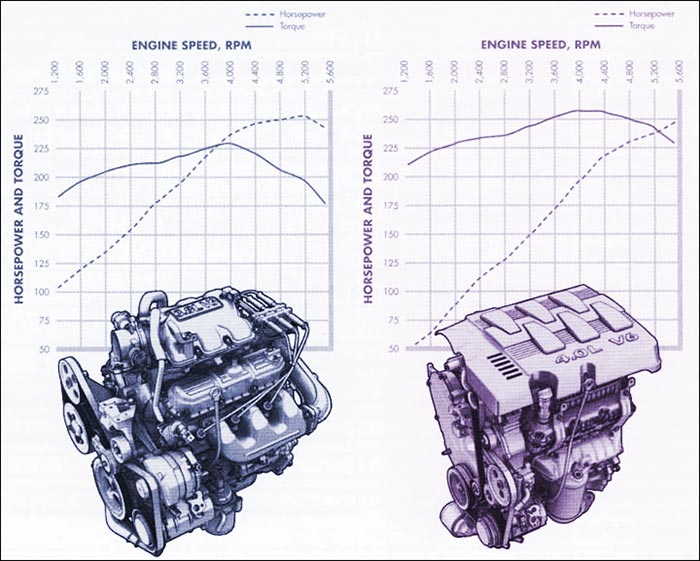

Chrysler added a half-liter of displacement to the 3.5 to create the new 4.0 liter V6 engine; it was only used in the 2008-12 minivans, 2007-08 Pacifica crossover, and the Dodge Nitro.

There are two possible reasons Chrysler made the new 4.0 V6. First, Honda and Toyota minivans started making more power than the Chrysler and Dodge; and second, and more likely, marketers and salesmen found it confusing that the 3.5 liter V6 would make more power than the 3.8, which was a stroked 3.3. The 3.8 minivan/Wrangler engine delivered far more torque than the 3.3, but usually no more horsepower. The 4.0 would solve both the displacement problem (“how can a smaller engine be more powerful?”) and the horsepower issue. The following chart shows that the 4.0 had peak torque similar to the 3.8, but boasted much better horsepower.

3.8 engine, left; 4.0 engine, right. The 3.8 descended from the original 3.3, the 4.0 from the 3.5.

This new engine was both powerful and efficient. It helped that Chrysler paired it with its six-speed automatic. In the 2008 minivans, the axle tuning was too aggressive, and applying heavy throttle often spun the front tires from a stop. But the next year’s revised axle ratio fixed that, and the 4.0 earned Chrysler the “most economical minivan” title. It even became standard on minivans; and the 3.3 finally left production, in 2010, five million engines after the first 3.3. The 3.8 liter engine was kept going for another year, but only under the hood of the Jeep Wrangler.

The 4-liter (241 cid) V6, as a stroked 3.5, added torque to an already strong and efficient V6. Horsepower barely rose, reaching 255, but torque went up to 262-275 pound-feet, with a broader curve. Crankshaft torsion was apparently an issue, along with extra vibration at the mounts, so the engineers changed the main bearings and their diameters; used lower-mass piston and rod assemblies; changed the block and oil pan structure; reduced less bearing clearance again, and added an equal-length dual exhaust. It still had the single-cam, 24-valve layout with hydraulic lifters and roller followers.

| (Pacifica) | 3.5 | 4.0 |

|---|---|---|

| Bore x stroke | 3.78 x 3.19 | 3.78 x 3.58 |

| Compression | 9.9:1 | 10.3:1 |

| Power | 250 hp @ 6400 | 253-55 hp @ 5,800 |

| Torque | 250 lb-ft @ 3900 | 262 lb.-ft. @ 4,100 |

| Fuel | 89 octane | 89 octane |

Chrysler still was using a timing belt and had no variable valve lift or timing system. It had already started working on the “Phoenix Engine,” which finally arrived as the Pentastar V6. This new engine was state of the art aside from not having direct injection, and was on Ward’s Ten Best Engines list for several years. As of 2024, the Pentastar V6 is still in production, with no end in sight.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos