When Francois Castaing became Chrysler’s head of engineering, he found engines which had fallen behind in performance, in some cases barely passing emissions tests. The best efforts of talented engineers had come up against strict budget restraints, holding Chrysler back from their prized powertrain leadership.

Castaing quickly ordered replacements for the four-cylinders and 318 V8, a high-tech version of their car V6, and a custom Jeep V6. These brought the 3.5 V6; the “Neon” 2.0 and 2.4; and the 3.7 and 4.7. There was just one engine left to replace: the 360 (5.9) V8, with roots in the original 1951 Chrysler “Hemi” V8.

Bob Lees, who had led the 4.7 V8 project, thought they could do better than a mere bore-and-stroke of his own new engine. He looked instead to hemispherical heads, used in Chrysler’s first V8s.

The 4.7 liter V8 High Output peaked at 270 horsepower and 330 pound-feet of torque—easily ahead of the outgoing 5.2 (220 hp, 300 lb-ft). The 5.9 engine was in the same ballpark.

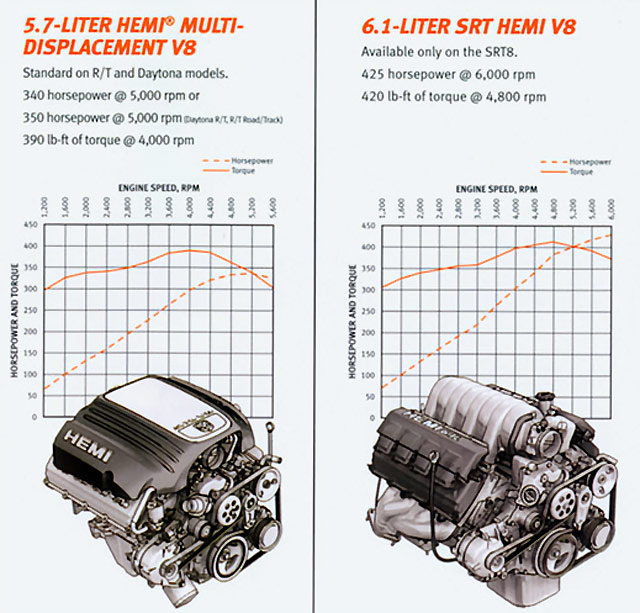

The new “Eagle Hemi” went far beyond, to 345 horsepower at 5,600 rpm and 375 lb-ft of torque at 4,400 rpm—one horsepower (net) per cubic inch on its debut in the 2004 Ram. SRT brought a more powerful 6.1 version with a stunning 425 horsepower, matching the gross rating of the fabled 426 Hemi. That was followed years later by the 6.4 at 485 horsepower, and finally a 2023 6.2 Supercharged hitting 1,025 horsepower.

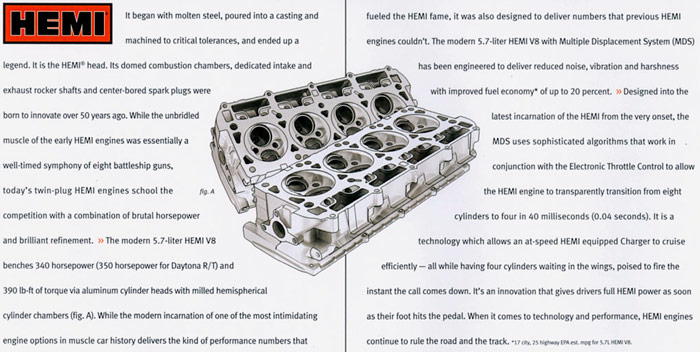

Fifty-six pounds lighter than the 5.9-liter V-8, the 5.7-liter Hemi produced 41% more power and 12% more peak torque at launch. There were several versions, differing partly in their air path, to suit the engine bays of various cars and trucks. The Dodge Charger ironically had less horsepower than the Ram 1500, but more torque. The car versions (Chrysler 300C, Dodge Magnum, Dodge Challenger, and Dodge Charger) had the “multiple displacement system” (MDS) which cut fuel to four cylinders when less power was called for.

| 5.7 | 2004 Ram | 2005 Charger |

|---|---|---|

| EPA mpg | 14/18 | 15/23 |

| Horsepower | 345 @ 5,600 | 340 @ 5,000 |

| Torque | 375 @ 4,400 | 390 @ 4,000 |

Despite having far greater power, the new Hemi V8 was cheaper to build than the old LA series 360 V8; it was reputedly cheaper than the “Next Generation” 4.7 V8, too. The new Hemi was 56 pounds lighter than the 5.9 (a reversal of the old “Hemi is heavy” mantra). The original Hemi had been expensive, heavy, wide, and hard to build, but decades of automation in the factories, advances in materials and valvegear design, and clever engineering resolved these problems.

| 5.7 | 2004 Ram Hemi | 2003 Ram 360 |

|---|---|---|

| EPA mpg | 14/18 | 12/18 |

| Horsepower | 345 | 245 |

| Torque | 375 | 335 |

The 2004 Hemi: more power, better mileage, and less weight, for lower cost.

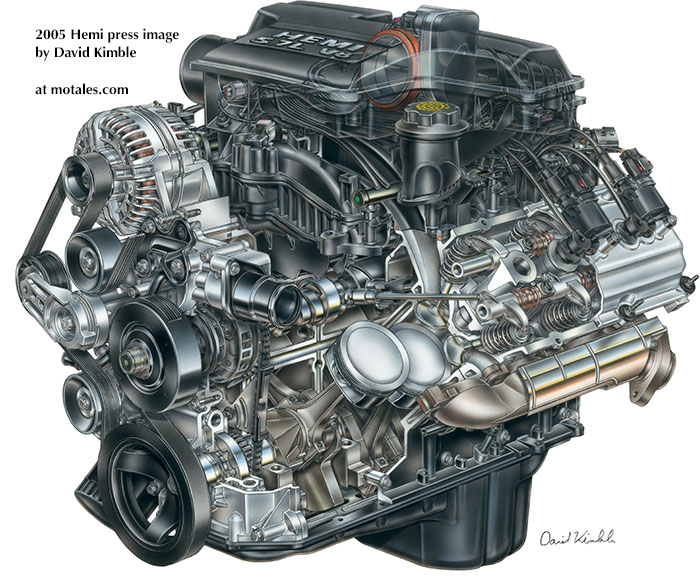

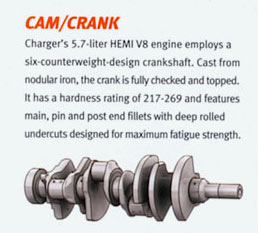

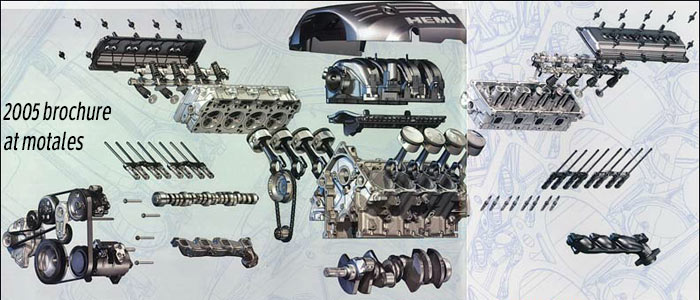

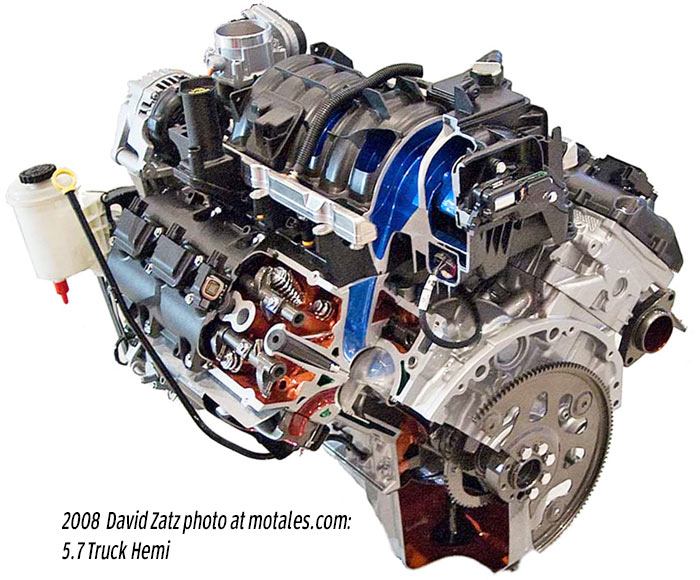

The meaty deep-skirt cast iron block was meant for durability in truck use, while the crankshaft was supported by two horizontal and two vertical bolts at each main bearing. The iron block was mated to aluminum heads and a plastic intake manifold which increased airflow. The factors that made the Hemi durable in trucks made it doubly durable in cars.

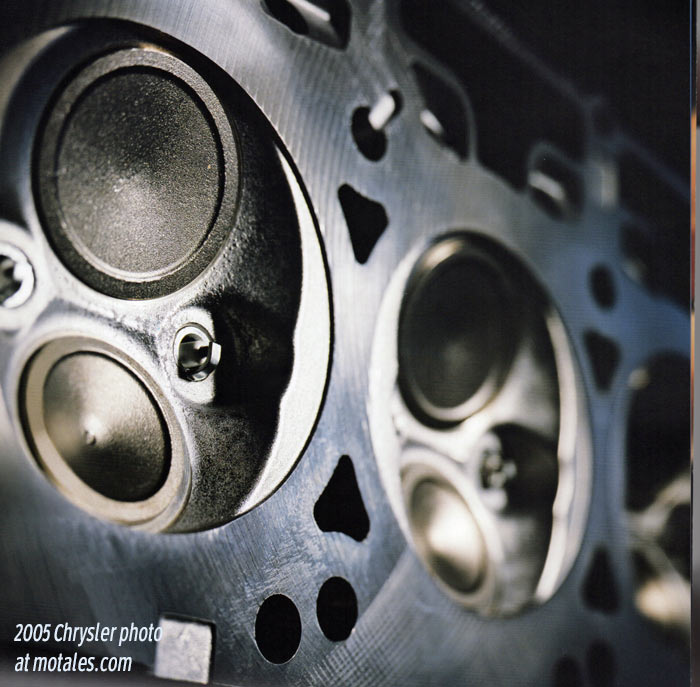

Both the Eagle 5.7 and the famed 426 Hemi, created for racing and only joined by a “street” version years later, had dual rocker shafts, with similarly sized valves (two per cylinder) in similar locations.

John Veatch wrote that the displacement of 345 cubic inches was the same as the first standard engine to reach one horsepower per cubic inch—the Hemi in the 1957 DeSoto Adventurer. (The later 1957 Corvette engine is often credited with this; but that engine was optional, as was that of the 1956 Chrysler 300 which had already reached one horsepower per cubic inch.) The modern version goes beyond the original, reaching one net horsepower per cubic inch.

At least two veteran engineers were involved. Tom Hoover, “Father of the 426 Hemi,” told Hot Rod that he suggested raising the camshaft to shorten the pushrods (reducing valve-train inertia and simplifying the rocker arms) and adding squish area for light-load efficiency and lower emissions. Willem Weertman, former head of engine design (Hoover’s boss), suggested using two spark plugs per cylinder to meet emissions rules. Some scoffed at the pushrod-operated overhead valves at first, but that scoffing did not last long.

Production began in June 2002 at the Saltillo plant in Mexico—the home of every modern V8; but the engine was not unveiled until the 2003 Dodge Ram pickup trucks were shown off in December 2002. A supercharged engine was shown to the public in January 2003, but until the Hellcat, the company set the superchargers aside in favor of other methods.

In 2005, Hemi engines were specified by around 45% of buyers on cars and trucks where it was optional. Former tuning chief Pete Hagenbuch joked at the time that it was the most successful Hemi ever, because it could be built at a profit.

The dual spark plug design, credited to both Willem Weertman and Tom Hoover, provided a second plug which fired during the power stroke to burn fuel more thoroughly. It also provided slightly more power in the downstroke, and allowed the main firing to be closer to top dead center. The main goal was cutting oxides of nitrogen and ozone.

Each cylinder had a coil pack over one spark plug, while the other had a wire running to a coil pack on the other side of the engine. Each coil pack fired both its own plug and a plug on the other bank of cylinders. That allowed for strong primary sparks while keeping just eight coils—saving the cost of eight coils and their mounting hardware on each engine.

In 2009, Chrysler claimed the cylinder deactivation (MDS) had saved around 100 million gallons of gasoline between 2005 and 2009, cutting carbon dioxide (CO₂) emissions by close to a million metric tons.

After the Cadillac “four-six-eight,” the 2005 Chrysler 300C and Dodge Magnum R/T were the first modern, high-volume cars in North America to use cylinder deactivation. It was part of the design goal from the very start. Bob Lee, Powertrain Product Team vice president, said this made it “elegantly simple and completely integrated into the engine design. The benefits are fewer parts, maximum reliability and lower cost.”

The system moved from eight to four cylinders in 0.04 seconds by closing the valves in half the cylinders. Some energy was lost through compression, but none by pumping air through the unused cylinders; so fuel economy rose by around 10% overall. Lubrication was handled by sending oil through the pushrods.

The system was ideal for V8s because of the engine’s balance on four cylinders; V6 makers would handle that, years later, by shutting just two cylinders. Today, even Mazda four-cylinders have a similar system, moving to two cylinders at times.

The Hemi always shut off the same cylinders; they tested the engines over many miles and found no serious wear patterns. The system did prove to be reliable but very sensitive to oil grades, and many early engine failures were traced down to mechanics using the wrong grade of oil.

It didn’t take long for an all-out-performance version, the 6.1 Hemi, to arrive for the Dodge Magnum SRT-8, Chrysler 300C SRT-8, and the Dodge Charger SRT-8 and Challenger SRT-8.

With that move, and especially once a 6.4 liter version with better fuel economy arrived, the 5.7 became more of an economy V8—though its power did not decline at all—and a mainstay for pickup trucks. In the Ram 1500 pickup, the 5.7 Hemi remained the top primary power engine—except for the Viper-powered Ram 1500 SRT and the later supercharged Ram TRX—until the 2025 models brought new twin-turbo Hurricane six-cylinders into play. Thus it became a truck workhorse while still providing quite good power for cars.

Still, the new Hemi was one of the few new engines of its era lacking variable valve timing. The next few years were spent addressing flaws and adding power and efficiency.

The second generation “Eagle” 5.7 Hemi had a clever hydraulic cam phasing system, which was inexpensive but effective; by moving the cam slightly, valve timing and lift was optimized for idle, low power, or high power. The camshaft (as before, a hydraulic roller setup) had oil passages to drive the cam phaser sprocket.

| 5.7 | 2002 Ram | 2009 Ram |

|---|---|---|

| Horsepower | 345 | 390 |

| Torque | 375 | 407 |

| EPA mpg | 14/18 | 13/19 |

The engineers also increased the compression ratio and airflow in the intake, heads, and exhaust. The active intake manifold, borrowed from the 3.5 liter V6, was based on Chrysler’s research in the 1960s. A flapper door switched air bewteen long runners and short runners, allowing either better torque at low engine speeds or higher horsepower at higher engine speeds.

| 5.7 | 2006 Charger | 2009 Challenger | 2011 Challenger |

|---|---|---|---|

| Horsepower | 340 @ 5,000 | 375 @ 5,800 | 379 |

| Torque | 390 @ 4,000 | 398 @ 4,200 | 410 |

| EPA mpg | 15/23 | 16/25 | 17/25 |

Other changes included new piston/rod assemblies with thinner walls and a stronger-alloy pins. Ports were redesigned, intake valves made 2mm larger, and the exahust floor was raised. Finally, the engineers specified a stronger crankshaft, dual-mass crankshaft damper, floating pin pistons, new valve springs, and higher capacity oil pump; some believe the new pump still didn’t have the capacity it needed.

| 5.7 | 2002 Ram | 2009 Ram |

|---|---|---|

| Horsepower | 345 | 390 |

| Torque | 375 | 407 |

| EPA mpg | 13/17 | 13/19 |

The horsepower rating of the little 5.7 was not nearly identical to the net power rating of the famed 426 Hemi; torque was not quite at 426 levels, but at over 400 lb-ft, it was still quite impressive. The effort involved in creating the 5.7 Hemi had turned out to be very well spent; the Hemi engine itself sold many cars and trucks, and the 4.7 V8 itself was dropped even after a “Hemi-style” head and valvetrain redesign gave it more power. There was just no point, with the Eagle providing similar gas mileage and much higher performance at the same (some said lower!) cost.

The correct grade of oil was essential; the owner’s manual is the only correct source, but the MDS engines have always used 5W20 oil. Two service bulletins, TSB 09-015-04 and 09-013-04, made that clear: “Vehicles with the Multiple Displacement System must use SAE 5W-20 oil.”

Some owners had problems with rapid cam wear. “AHBguru” talked to police fleet mechanics (keeping in mind that police use is quite harsh on engines) and found that the final update to valve lifters was made in early 2019, with trucks getting the new parts in January and other engines upgraded by March. They superceded all prior lifters, across the board, from 2005 to 2019 (save for the old pre-MDS truck engines).

The latest and greatest lifter update occurred in early 2019. New trucks started getting the lifters that January, everything else by that March; the new parts replaced all prior lifters in MDS (cylinder deactivation) 5.7 Hemi V8s from 2005 to 2019, and were available for ordering at dealerships. These apparently resolve issues with cam and lifter failure, though not from use of the wrong oil and so on. Replacing lifters and cams costs under $2,000, taking around ten hours. Chrysler also added a new standard procedure of dropping the oil pan for inspection since cam or lifter failure often also hurt the oil pump and pickup.

“Hemi tick” can, according to Allpar’s Mentallica, be a lifter tick; a failing MDS lifter; a broken exhaust manifold bolt; a cracked manifold or head; or a bad seal on the exhaust manifold—or any number of other things. On top of that, the engine normally does make a relatively quiet tick on startup, quieting down fairly quickly. A loud tick should be addressed. Some believe the issue came in with MDS, but that doesn’t appear to be true. Geoff Gariepy clarified the normal tick—“very briefly sounds like a diesel engine’s clatter on startup. After a second or two, that's gone, and it’s replaced by a very mild ticking sound reminiscent of a valve train noise.”

AHBguru added that broken exhaust bolts are uncommon on cars and Jeeps, and more common on Rams. Cracked intakes are unusual, as are cracked heads; but bad head gaskets, dropped valve seats, and broken valve springs are more common. He also noted that Chrysler seems to be recommending engine replacement when the VVT solenoid is plugged with debris from a cam or lifter failure.

In 2018, the engines team reportedly worked on increasing 5.7 Hemi fuel economy in Project Warthog (changed to Hercules by voting after the PR group asked for a change). It was reportedly dropped due to the cost of retooling the plant; they also had to overcome emissions issues and problems with “flat map” or “lambda 1” behavior.

In 2025, Ram put the Hemi back into production, but it was not easy. To save money, FCA/Stellantis had reused the Hemi’s assembly lines, after running off thousands of spare engines, to make the new Hurricane I-6, a twin turbo design that produced more power with 10% better fuel economy, on regular gasoline.

Even after investing billions in development and production of the Hurricane Six and ending V8 sales in the Ram 1500, Stellantis did no real publicity for the Hurricane after its unveiling. Marketing didn’t drag-race it against the Hemi, have a “Hurricane experience” at car shows or races, etc, do comparison ads—it was almost as though some executives didn’t want the new engine. Eventually the Hemi was brought back, but it required investing in new equipment. Much of this was automated and flexible, able to handle a low-speed line potentially producing all three Hemi designs and possibly a new, more advanced V8.

It’s possible that the Hercules updates are part of the new run; power ratings are identical to the old engine, but there could be minor updates for durability and fuel economy. The company did not comment on this. The equipment is to be in place in August and will arrive for the 2026 Ram 1500, possibly followed by the Grand Cherokee, Durango, and/or Wagoneer. For the moment only the 5.7 version has been announced, and it will cost buyers $1,200 over the price of a Hurricane Six.

In the meantime, the Ram 1500 had moved on to a new electronics system; adapting it to handle the Hemi V8 took some doing, largely using modifications created for the Wagoneer.

The cam was hollow to reduce weight, and had oversized journals and lobes to reduce lifter side loading. The company used the beehive valve springs it had invented, which could be made lighter but still have less lifter collapse. The light rockers had just .500 inches of lift in the early engines, but the high airflow of the Hemi design made this acceptable.

Precision casting cut weight off the block despite its high deck height; the skirt was coated to reduce noise and make the range of ring seal sizes larger. The cast eutectic alloy slipper-style pistons weighed just 413g; they were anodized on the top ring to provide a heat barrier and anti-micro-weld mix. That also let the engineers move the top ring to just 3 mm from the top of the piston. Thin rings presumably reduced friction, while a groove under the top ring cut pressure between the top two rings.

A windage tray was standard to prevent oil shortages. The serpentine belt pulley doubled as a vibration damper. No balance pad was needed as the connecting rods were strong and light.

The ports had peak flow at 0.375 inches. Popular Hot Rodding compared intake and exhaust ports favorably to the GM LS6 V8 engine.

Chrysler used its usual a speed density system instead of a mass airflow sensor.

Courtesy Cole Quinnell and Allpar

| Bore x Stroke | 3.92x3.58” 99.5x90.9 mm |

| Max deck width at face | 18.3 inches 464.8 mm |

| Block height | 15.4 inches |

| Engine length | 21.1 inches |

| Chamber volume | 84.9 cc (5.18 cid) |

| Intake valve angle | 18° |

| Intake valve diameter | 50.8mm/2.00” |

| Exhaust valve angle | 16.5° |

| Exhaust valve diameter |

39.4mm 1.55 inches |

| Oil Capacity | 7 qt / 6.6 l |

| Weight* | 485 lbs |

* Weight includes manifolds, wiring, flexplate, and exhaust manifolds, but not accessories such as alternator

Crank centerline to...

| head deck face | 9.3” |

| cam center | 7.4” |

| oil pan rail | 2.6” |

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos