The “World Gasoline Engine” (WGE) series wasn’t really needed, but it was pushed into place not long after Daimler took over Chrysler Corporation, creating DaimlerChrysler. The series had three engines: 1.8, 2.0, and 2.4 liters, as well as a very potent turbocharged version from SRT.

Chrysler’s own 2.0 and 2.4 liter engines were still fairly new, having debuted in the 1995 Neon and 1996 Voyager/Caravan. The 2.0 was a little brash, but tough, enduring (and dominating) SCCA compact-car racing. The 2.4 liter version was smoother and quieter. It did lack variable valve timing, but that didn't require a new block. What did require it was DaimlerChrysler’s leaders, who wanted to get Hyundai’s automotive business. They had bought 10% of Hyundai’s car business, and wanted to get the rest, preferably for free via merger.

Hyundai had started really creating its own cars after building Mitsubishis under license, but engines were their weak point. DaimlerChrysler (“the Chrysler is silent”) brought in Mitusbishi (which it was also trying to buy), Chrysler, and Mercedes to all bash Hyundai’s latest design into shape; the company’s leaders figured Chrysler would make all the engines in a new Michigan factory, with blocks from Wisconsin’s J.L. French, and sell them to Mitsubishi and Hyundai. In the end, Daimler ended up teaching Hyundai how to design better engines, and neither of the other automakers stayed in the alliance much longer—or bought engines from Daimler. The result was an underused Michigan factory.

Each of the three companies made its own engines, using a common block but different heads, fuel delivery, and so on. Reviewers ironically preferred the Hyundai version, calling the Chrysler version rough, peaky, and noisy. Still, it was cheaper to build than the prior engines, and had higher peak power ratings. Like the 2.0 (after a head gasket swap in 1998) and 2.4, the new World Gasoline Engines (WGE) were reasonably long-lasting.

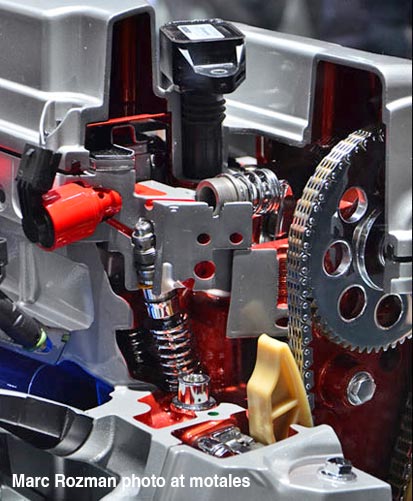

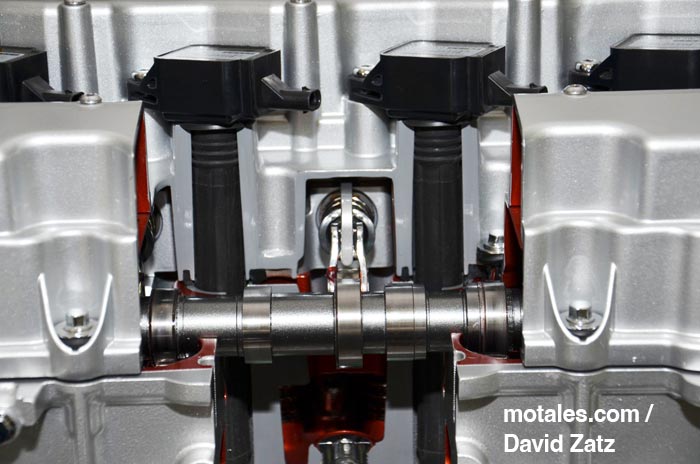

The Mercedes dual variable valve timing (VVT) was the first dual VVT system for entry-level cars. It used oil pressure to adjust cam phasing; the slight overlap at idle increased at speed to re-burn exhaust gas without a pump. The exhaust cam could move through 35°; the intake moved through 40°. Cams rode on tappets matched to the individual heads, with dozens of slightly different tappet sizes. The tappets used shimless mechanical buckets.

The flow-control valve intake manifold was also an improvement, as Chrysler relied on pressure sensors instead of flow sensors. This time the engineers expected forced induction, so each cylinder was surrounded by water jackets for extra cooling. (The turbocharged version arrived for the Caliber SRT4 a few years later).

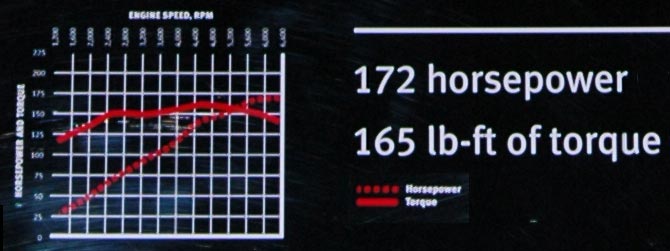

The 2.4’s 172 horsepower and 165 lb-ft of torque beat the 150 hp Neon-based 2.4, but it didn’t do as well off idle and buzzed quite a bit, despite the isolated valve cover and damped oil pan. The bell housing had a tight connection to the transmission to reduce oil leaks in high-mileage engines, which hadn’t been much of an issue before. It had a plastic intake, like the Neon 2.0, with equal length runners. The computer opened built-in valves to increase air tumble (by blocking over half the port) at speeds under 3,200 rpm.

The WGE engines (1.8, 2.0, and 2.4) used the same block with different strokes and piston liners. They used short-skirt pistons with friction-reducing graphite patches. The crankshaft was forged steel, with an integrated oil pump. Pistons and bearings were matched to blocks to reduce machining.

The million-square-foot GEMA plant, later renamed to just Dundee, cost over $700 million; each of its two plants had capacity of 420,000 units per year, but may never have reached that point. The lines in the surplus building were moved to Saltillo and Trenton.

When Fiat acquired the former Chrysler, they started going after the weak spots, one of which was the buzzy sewing-machine WGE engines. Critics and customers both threw shade at those four-cylinders, whose advanced features couldn’t overcome their problems. The priorities for the next generation were noise and responsiveness.

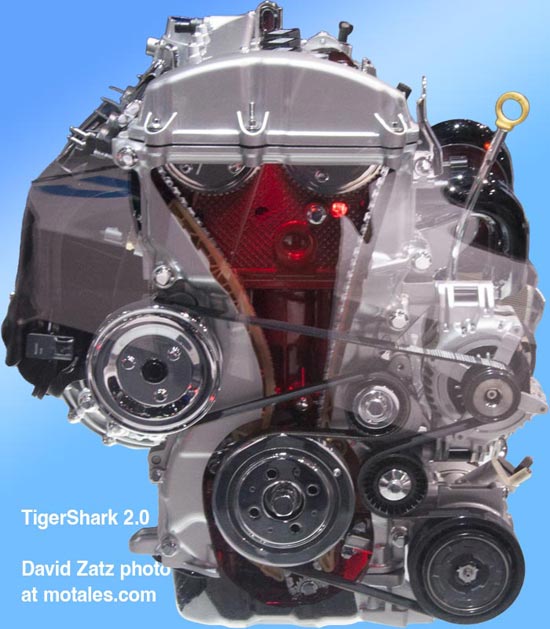

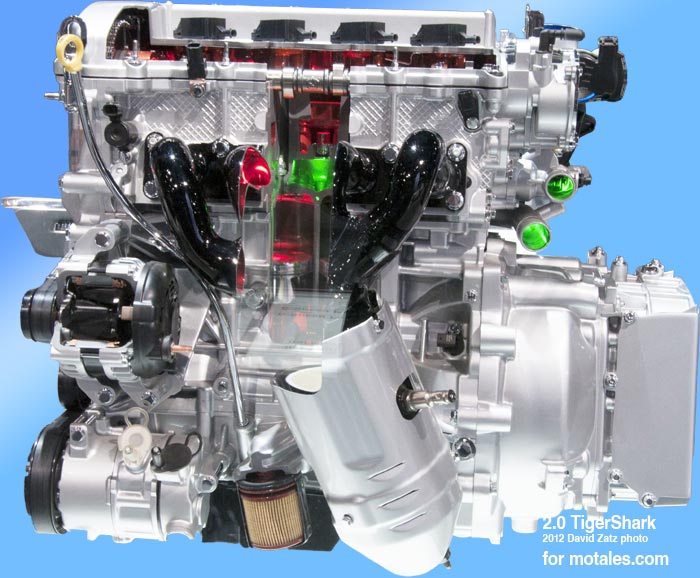

Production of the new TigerShark version began in the Trenton Engine Plant in Michigan in 2013. The 1.8, an oddball created with thicker cylinder liners, was consigned to history; the 2.0 and 2.4 were shared by the Cherokee, 200, Dart, Journey, ProMaster City, and Renegade, with a production goal of 600,000 per year. The 2.0 was made in Dundee; the 2.4 was made, at one point, in Dundee, Saltillo, and Trenton.

The TigerShark was quieter and made more power at lower revolutions. Noise was cut by an isolated aluminum head cover with an integrated oil-separation system; an aluminum ladder frame with an intregral oil filter and oil cooler adapter between the block and the steel oil pan helped, along with acoustic material between the oil pan’s outer and inner stampings. Polymer-coated piston skirts and tighter piston-to-bore tolerances cut noise and vibration, too. Other changes were made to add stiffness, cutting vibration and noise.

The 2.4 had cast steel main bearings, the middle three being bridged for added stiffness, and a 41-pound forged steel crankshaft, now with powder-forged steel connecting rods and full floating piston pins. Each bore had oil squirters to cool the pistons and bore walls.

To broaden the power curve, both the 2.0 and 2.4 had new variable valve timing systems. The 2.0 had new intakes and roller cams, doing away with buckets on the valve springs. The 2.4 switched to Fiat’s MultiAir 2, a variable valve timing and lift setup with separate timing for each cylinder. Solenoids varied the amount of oil sent to actuators which changed the timing and lift—the latter, from completely closed to completely open.

The Tigershark has a two-stage oil-pressure relief system that reduced pumping loads at low engine speeds. Both generations used coil on plug ignition, and a front accessory drive with automatic tensioning.

| 2008 | 2013 | ||

|---|---|---|---|

| 1.8 | HP | 148 @ 6,400 | none |

| Tq | 125 @ 4,400* | none | |

| 2.0 | Hp | 158 @ 6,400 | 160 @ 6,400 |

| Tq | 135-141 @ 5,200 | 145 @ 4,800 | |

| 2.4 | Hp | 172 @ 6,000 | 184 @ 6,250 |

| Tq | 165 @ 5,200 | 171 @ 4,800 | |

| SRT | Hp | 285 | none |

| Tq | 260 | none |

* Also reported as 124 @ 5,500 rpm

The valve system was always chain driven, with dual overhead cams. The 2.4 liter engine displaced 2360 cc (2.36 liters), or 144 cubic inches. All the engines had sequential, returnless fuel injection and ran on regular 87-octane fuel. The redline was 6,500 rpm. The TigerShark 2.4 head weighed 42 pounds (39 without the valves), and the block weighed 70 pounds.

| WGE | TigerShark | |

|---|---|---|

Bore x Stroke |

3.46 x 3.82 (88 x 97) |

|

| Valve Timing | Cam phasing | MultiAir |

| Tappets | Shimless buckets | Rollers |

Power |

129 kW |

138 kW |

Compression |

10.5:1 | 10.1:1 |

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky