As reported to the American Manufacturing Association by Chrysler Corporation, 1974, for the Plymouth Valiant, Duster, and Scamp. Truck engines were somewhat different (e.g. in valve construction and possibly carburetors) and there may be minor differences, especially in cooling, for bigger cars. The 198 replaced the 170, so that both slant sixes would use the same block; the extra cubic inches also helped replace power lost to emissions controls.

Unspecified figures are in inches!

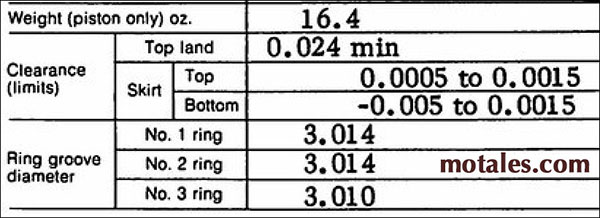

While early engines could be made of aluminum, by 1974 they had dropped these and every slant six used a cast iron head and block. As such, there were no cylinder sleeves. Pistons were a tin plated aluminum alloy (closed slipper-type) with steel struts.

Piston rings: top to bottom, the first two were for compression and the third was for oil. Compression rings were cast iron, twist and taper faced; the first was tin plated and the second was lubrite coated and reverse twist and taper. Width was 0.078 inches. The oil ring was a three-piece variety of stainless steel, with chrome-plated segments.

Bore: 3.40 inches; Stroke: 3.64 and 4.12 inches

Bore spacing: 3.98” between all cylinders except 2-3 and 4-5 (4.00”)

Firing order: 1-5-3-6-2-4

3° incline from rear to front, as installed in the Valiant/Dart/Duster/Swinger

Recommended fuel was listed as 91 octane (premium), which is almost certainly a mistake.

Head volume: 57.0-60.0 cc for both versions; head gasket volume 3.33 to 3.69cc; head gasket thickness: 0.021 to 0.023 inches, when compressed

Daniel Stern suggested using cooler spark plugs than the ones originally recommended, since gasoline is better than it used to be. The original specification plug on 1974 and earlier engines was the Champion RN14YC, but some on the slantsix.org forum recommend NGK ZFR5N, minus the crush washers, and gapped at the stock 0.035 inches. A head redesign in 1975 finally eliminated the spark plug tubes; for these, Daniel Stern recommended the NGK UR5GP.

The pins were carbon steel, while rods and the crankshaft were drop-forged steel (the crank later changed to a cheaper design). Crank end play was to be 0.002-0.010 inches. Bearings were lead-based babbitts on steel.

The cam was made of hardenable cast iron, with a sintered iron (“Super Oilite”) timing chain. Cam sprockets were nylon-coated aluminum, for quietness. There were 50 links in the timing chain, 0.88 inches wide, with a half-inch pitch.

Valves: intake valves were set to open at 16° BTC and close at 48° ABC, with 244° duration. Exhaust valves opened at 54°, closed at 18°, with the same duration. The valve open overlap was 26°.

| Intake | Exhaust | |

|---|---|---|

| Length | 4.77 | 4.80 |

| Overall head diameter | 1.62 | 1.36 |

| Valve seat angle | 44.5°-45° | |

| Face angle | 45°-45.5° | 47°-47.5° |

| Insert material | none | induction hardened |

| Lift at zero lash | 0.406” | 0.414” |

| Intake valve clearance (hot) | 0.01” | 0.020” |

| Outer spring pressure (closed) | 60 lb @ 1.65” | |

| (open) | 160 lb @ 1.24 | |

Tappets were splash-lubricated while cam bearings, rods, and main bearings were pressure lubricted; rods were sprayed. The oil pump was rotary with 45-65 psi at 2,000 rpm. The filter was a full flow design. Numerous oil grades were recommended; for weather consistently below 10°F, 5W20, 5W30, and 5W40 were recommended. For warm weather, various weights were allowed, but 10W30 and 10W40 were commonly used.

The exhaust was a single muffler and tailpipe, with a crossover on the 225 but not the 198; the quiet package added a resonator.

| Intake | Exhaust | |

|---|---|---|

| Main pipe diameter | 1.75 | 2.00 |

| Wall thickness | 0.067 | 0.067 |

| Branch* | 1.75 dia. | |

| Tailpipe diameter | 1.88 | 1.88 |

| Tailpipe wall | 0.043 | 0.043 |

* Quiet package only

Every slant six made had a carburetor when it left the factory. Until 1977, they were single-barrel carburetors. The 1974 spec called for 3.5 to 5.0 psi from the fuel; idle speed was 800 rpm for the manual and 750 rpm for the automatic, with a 14.3:1 idle air-fuel mix.

The 198 and 225 had different carburetors, both supplied by Holley, though they were extremely similar. The barrel was 1.69 inches for all of them; the model numbers were R-6721A through R-6724A, for the 198 manual (1), 198 auto (2), 225 manual (3), and automatic (4), except in California. Chrysler only sold the 225 in California, not the 198; those had the R-6725 and 6726 models. The differences are unclear.

For 1974, the 198, 225, 318, and 360 all had similar cooling systems, operating under 16 psi and with 195°F thermostats. The cooling system took 13 quarts including the heater—one more quart with air conditioning. The radiator hose had an inside diameter of 1.50 inches (upper and lower), while the bypass hose had a 0.68” inside diameter.

Without air conditioning, the fan had four blades, with a 17.5 inch diameter; with air, buyers went up to seven blades, with an 18 inch diameter, and a fan shroud.

Emission controls were mainly exhaust gas recirculation (EGR), crankcase vapor burning, and fuel vapor burning.

See our main slant six page... and Making slant sixes at Trenton Engine ... and slant six tips

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky