What was in a Chrysler factory in the 1950s? It was a surprising amount of gear, but consider that they had to take care of thousands of employees, who ate and drank; there was always a risk of fire; they had to build cars; and they had to build and repair the machines which built cars. It is almost unbelievable how much equipment and property goes into a plant; and it was all tracked.

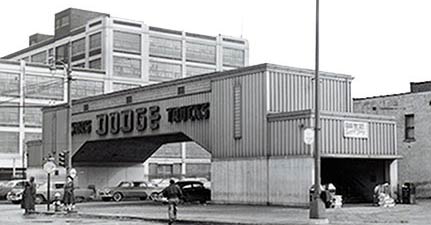

Dodge Main in the 1930s—a massive plant complex

One reason for the need to equip plants so completely was the lack of centralization. Plants made and repaired much of their own equipment, having their own tool engineers and designers. They had plant engineers, master mechanics, assistant master mechanics, and so on; Dodge Main even built its own engines until Trenton Engine took over its V8 production. Each discipline required staffing and its own equipment, right down to the paper and pens and blueprinting equipment required by engineers and draftsmen.

Some examples of specific categories are:

Power: Power house (generating or transforming outside electrical and sometimes steam power), transmission systems, motors, generators, starters, wiring, belting, hangers and bearings, countershafts, pulleys

Communication: Teletypes, telephones and switchboards, vacuum tubes for sending letters around

Materials handling: Conveyors, elevators, cranes (steam, electric, hand), hoists, trucks, battery chargers, racks, bins, pumps

General building: Floor loading equipment, paint, glazing, janitorial gear, groundskeeping equipment, ice

Oil and bas burners; fuel and lubrication oil and supply systems for the oils; gases (e.g. oxygen and simple air); gasoline; lacquer (paint); brake and other car fluids; oil clarifiers; spray booths; ovens for baking cars; regulators; recorders; numerous tanks for holding fluids; tracks for equipment to run on; air washers; testing equipment of all kinds (block testing, dimensional testing, etc.); chip and boring disposal; and scrap bailers.

... and equipment for enameling surfaces; heat treating; acid cleaning; pickling; plating, galvanizing, Parkerizing, and bonderizing; and all nature of gear for the foundry.

Plant Engineering repaired its own equipment, normally; Tool Room or Machine Repair could also make repair parts with permission from the master mechanic.

The Master Mechanic would oversee:

1. Actual production

2. Where applicable, Foundry, Pressed Steel, Body Shop, Screw Machines, Transmission, Engine Parts and Assembly, and Wiring Harnesses; Sheet Metal; and Machine Shop. The last two were the same shop except at Dodge Main; Sheet Metal included die engineering, design, followup, and die shop; and a body fixture shop.

Within Machining, there was tool engineering; design; trouble; followup; and Tool Room. There was also Machine Repair, Cutter Grind, a grinding wheel and belt room, and various tool stores and cribs. Tool design required draftsmen. Machine Repair might be responsible for thousands of machines, some of which they developed internally.

Source: Chrysler Institute of Engineering materials supplied by Al Bosley; background knowledge.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos