The new 2.0 liter four-cylinder GME EVO engine is a major move forward, using lessons from the first Global Medium Engine (GME) and the Hurricane Six. It combines the skills of engineers formerly at Chrysler, Fiat, Peugeot, and Maserati, and probably there's some Ferrari in there too—the “race inspired” turbulent jet ignition system, already used by Maserati. Overall, the engine is a tour de force.

Before we get into performance, it’s worth dismissing social media complaints from people who saw “high powered turbo four” and wrote the Hurricane Four off as a buzzy, disposable engine that can’t tow (the Grand Cherokee is rated at 6,200 pounds of towing with this engine). It starts with a Kokomo-made single-piece die-cast deep-skirt aluminum block. No, it’s not iron, but it is a deep skirt design with 24% thicker bore walls than the prior GME 2.0 turbo. It has a die-cast aluminum oil pan and timing cover, as well, with larger main and connecting rod bearings on the crankshaft than the old 2.0.

The engine includes a structural windage tray and balance shaft assembly, mounted low, and a viscous crankshaft damper to reduce vibrations. Along with the deep skirt design with more meat around the cylinders and attention to various accessories, this should keep the engine from being “buzzy.”

To reduce space, the engine uses a PTWA process where a steel alloy wire is melted at 4150°F inside the cylinder; microscopic particles splat-cool to coat the bore, replacing Chrysler’s traditional and cheap liners with something more uniform and having ten times the wear resistance. The surface is then honed for a fine cross hatch pattern that has controlled micro-porosity for oil retention. The spray process leaves more aluminum between the cylinders, which improves heat transfer and, therefore, engine cooling.

Like past Chrysler truck, marine, and industrial engines, the Hurricane Four uses sodium-filled exhaust valves which manage heat. The block has cross-bolted steel main bearing caps, and the crankshaft is forged and twisted steel. Rods are also forged steel; pistons have DLC coated piston pins. The engine is, in short, built for the power it produces.

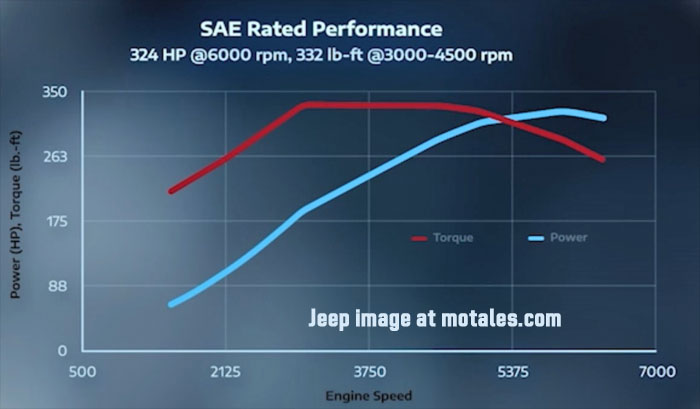

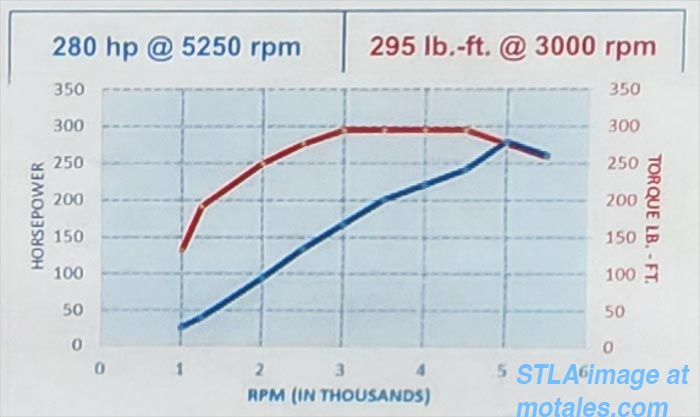

The engine appears to get around 1 mpg (combined) better economy than the 293 hp/260 lb-ft Pentastar V6, but provides 324 horsepower and 332 pound-feet of torque, a major boost, especially in torque. Peak torque covers a wide range, 3,000 to 4,5000 rpm. Nearly 300 lb-ft of torque is available from 2,600 to 5,600 rpm—that’s more than the Pentastar’s peak! That likely makes this engine far better for towing and ordinary driving.

Above: new Hurricane Four (GME EVO). Below: GME 2.0 Turbo.

Micky Bly, head of global propulsion systems, said, “The Hurricane 4 Turbo name is appropriate because this engine packs a punch, ... 162 horsepower per liter of displacement... The clean sheet design gives our customers a powerful, refined, smooth-running engine that uses 10% less fuel to deliver 20% more power than our current 2.0-liter DOHC I-4.”

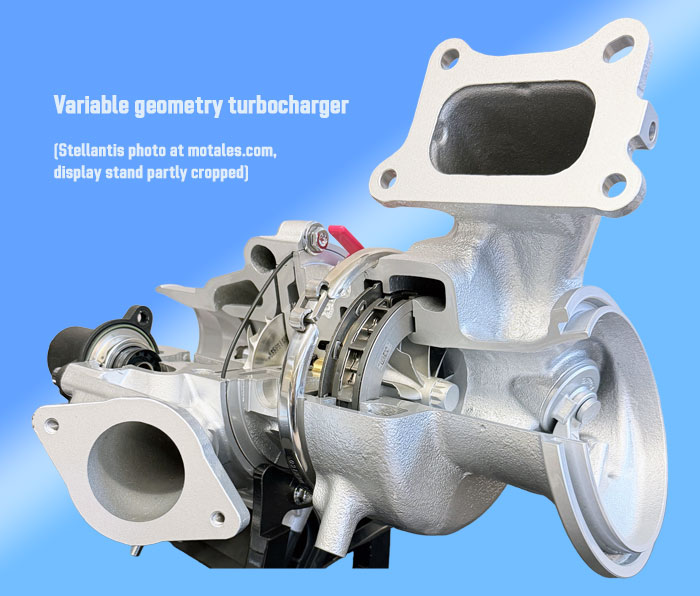

The variable geometry turbocharger is not really new tech; it was pioneered by Chrysler and Garrett in the 1991 Turbo III engines, and is now commonplace. The single turbocharger (not a dual scroll setup) delivers a nice 35 psi (2.4 bar), and has a charge air cooler, which people often and wrongly call an intercooler.

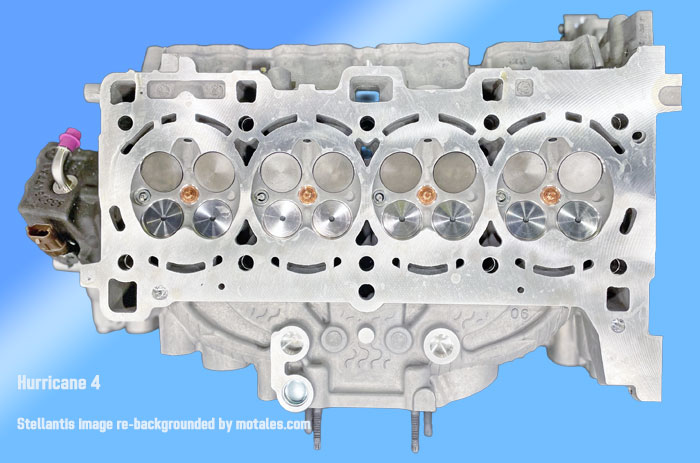

The turbulent jet ignition (TJI) is the most uncommon technology: it lights a little fuel in a pre-chamber atop each cylinder first. That fuel/air mixture jets into the chamber, triggering a fast, complete burn (helped by a second spark plug), increasing both performance and efficiency. It has two spark plugs per cylinder, but they are not used in the traditional fashion, so no, Alfa Romeo does not get credit here.

The aluminum cylinder head contains four valves per cylinder and overhead camshafts. The TJI chamber is press-fit into the center of each combustion chamber. Variable intake timing is adjusted quickly by an electric camshaft phaser, which should react more quickly and last longer than a hydraulic one. The engine runs on a Miller cycle, closing the intake valves early to lock in power and reduce emissions, allowing an absurdly high (for a turbo) 12:1 compression ratio without knock, on regular fuel.

Many people are afraid of direct injection, because early direct injection engines tended to carbon up and fail. The solution to that has been known for years: using port fuel injection as well. This engine uses both, with 5076-psi direct injection and port injection alike. Both are used on cold starts and typical power loads, but at low load and idle, they only use port injection, which cuts particulates and noise, and deals with any particulates left by direct injection.

The deep-skirt cast-aluminum block had cross-bolted steel main bearing caps, low-friction plasma spray-bore coated cylinders, and a structural diecast aluminum alloy oil pan. The head is aluminum alloy head, with pent-roof combustion chambers. The crankshaft is forged and twisted steel, with forged steel connecting rods. Pistons are cast aluminum alloy with DLC coated piston pins.

The water pump is electrical and the oil pump has variable displacement, to avoid parasitic losses. Regular fuel is recommended, rather than premium. Misfire detection comes via ion sensing. The intercooler is the usual liquid-to-air type.

The Hurricane Four is made in Dundee, Michigan, and will also be made in Kokomo, Indiana. The block is made in Kokomo, including the bore lining application.

The following photo is a GME 2.0, “first edition,” for comparison.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos