Aside from a those still covered by free trade agreements, Canadian and Mexican cars and parts are slapped with a 25% import tax as they enter the United States, and vice versa. After July 1, 2026, when the North American free trade agreement expires, every single car and part will have a 25% or higher tax; President Trump has threatened to increase taxes as well. One fast result of this was Stellantis’ decision to stop work on the factory in Ontario (Brampton) which was to make STLA Medium cars, such as the new Jeep Compass, already on sale in Europe.

The sudden onset of taxes, not authorized by Congress and therefore coming without much warning, took Stellantis, the owner of Chrysler marques, by surprise. They were still investing massive sums of money into converting its Windsor, Ontario and Toluca, Mexico plant to the new STLA Large platform, and were making the Charger Daytona and Wagoneer S EVs in the two countries. Suddenly, it appeared as though both vehicles would be hit with 25% taxes when sold in the United States. Given that these taxes are likely to not only be permanent but to spread to every car and part shipped across the border, Stellantis has some tough decisions. In some ways, though, they were made easier by the U.S. government’s decision to revoke all penalties for violating corporate fuel economy standards, coupled with likely easing or entire dropping of emissions standards by a defanged EPA.

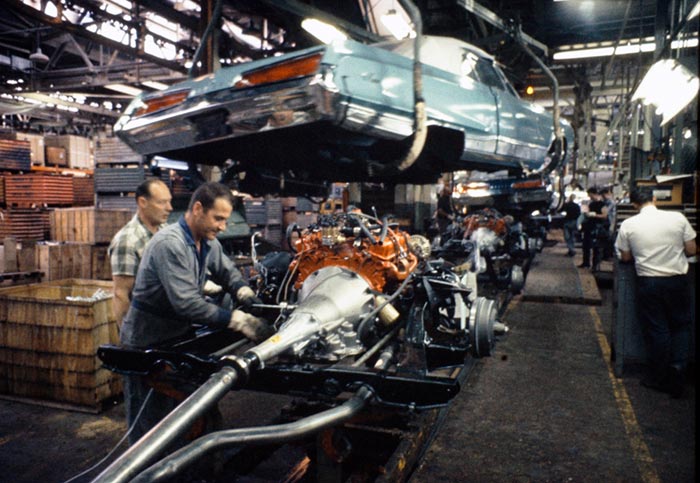

For much of the 20th century, India had high tariffs; Chrysler had to make cars for Australia locally, sourcing parts there as well. Indeed, many countries made it hard to import cars profitably, hoping to gain domestic jobs. This tended to result on pricier cars in smaller countries, but it was seen as worthwhile to create domestic industry.

Today the world is a net of overlapping free trade groups, but the obvious outcome is making cars and parts in the United States, solely for the United States (except some slow-selling, exotic models like Imperials and some muscle cars were), while making cars elsewhere in any convenient country. Canada and Mexico are already working on being trade-integrated with nearly every other country on Earth.

With fuel economy standards gone and development on the US version of the Jeep Compass reportedly paused, it seems likely now that previous speculation on Belvidere being converted to STLA Medium is no longer valid. Indeed, it looks as though the former Chrysler will lean heavily on Ram and Jeep, use Dodge as a sort of muscle car exotics maker, and likely drop Chrysler when minivan sales drop below the minimum threshold or when the anniversary year is over.

This leaves us with:

Sterling Heights and Warren, the new and old truck plants, are likely to make all Ram pickups (along with the related Jeep Wagoneers). We now know that heavy duty Rams sell nearly as well as the Ram 1500. Saltillo may continue at very low volumes for the rest of the world, making a parallel linup. Chassis cabs, which have not been updated much since Daimler, would likely disappear when sales finally fall too low, rather than be transplanted. ProMaster, given relatively slow sales, could be phased out over time, or replaced by a new adaptation of European vans—it’s now unique at Stellantis, its basic chassis having been replaced. Hurricane I-6 engines might be imported, or made in the United States, but they might also be dropped in favor of the V8s which are less powerful and less economical, because some simply prefer V8s.

Belvidere was a candidate for STLA Medium, including the Compass. This would be relatively cheap and easy if most of its KL Cherokee equipment is in place or in storage. At this point it’s supposedly earmarked for a new midsized pickup truck. Its actual destination is unknown, but crews of people are still at the plant, which Stellantis claimed they would turn into a distribution center despite the large warehouse and sequencing center right across the street.

Detroit Complex factories (formerly Mack Engine I and II, and Jefferson Avenue Assembly) which currently make Grand Cherokees and Durangos could switch to producing the entire STLA Large line (Charger, Recon, Cherokee, future Grand Cherokee, future Durango, and future Pacifica), three per factory. Given that the electric Wagoneer S is likely to be dropped, and that the electric Charger Daytona might or might not continue, this is not as difficult as it might seem; and there’s no rule that Chrysler must make a minivan, if sales collapse as they have in the second quarter of 2025, when Chrysler was even outsold by the Kia Carnival. Chrysler has had flexible plant technology for decades, though Fiat didn’t have much use for it.

Toledo is a pair of factories pumping out Wranglers, and could add a second pickup, if there is one to be added that is body-on-frame, reducing pressure to sell Wranglers and Gladiators. That would be good since Gladiator sales have dropped.

Refitting a factory is a many-million-dollar expense, and fully committing to a US-or-Global dual factory strategy is a risk, since there could be midterm elections in 2026 resulting in Congress ending the import taxes in 2027; or the President could have a sudden health crisis, and the taxes could be dropped by the vice president. If that happens, money spent on factory moves would have been a waste.

While Stellantis, like most large companies, is unlikely to be overly concerned by it, there are also human and society costs to be paid for closing factories. Chrysler has long been proud of the quality of its Toluca and Windsor factories, in particular; Brampton has also produced high quality vehicles, to the extent its body shop permitted. Canada and Mexico have access to numerous trade networks and are tightening ties to Europe; Canada is even working on its insane internal trade barriers. Still, Canadian sales are only 12% of US sales or so, Mexico is to Canada what Canada is to the US, and Europe doesn’t really buy the supersized cars popular in the United States. Australia is one possibility, but the nation/continent is already flooded with Chinese, Japanese, European, and American cars and trucks. How many more Rams and Dodges and Jeeps can Australia import from Canada or Mexico, on the other side of the globe?

For the same reason, it would probably not pay to make Wranglers and Gladiators elsewhere. They would be competing with Broncos and maybe Scouts afflicted by the same taxes, and aren’t really all that popular outside the United States. One could see Stellantis, though, using Wrangler’s basic design for a cheaper off-road vehicle for Australia and Africa and South America—but they might end up competing with Mahindra and other cheaper suppliers, not to mention the current standard (Toyota) and Land Rover.

There is no really positive outcome for Stellantis. Indeed, most major automakers will be bleeding regardless of their choices; but Stellantis might have backed itself into a corner more than most.

EP6 / PureTech. Peugeot 1.6 liter turbo engine made at Dundee, likely ~280-380 hp, reportedly to use Punch Powertrain automated manual transmissions with integrated motors. Jeep Cherokee is the likely first use.

Pentastar. 3.6 expected to continue on for the foreseeable future. Still made in three versions, one for PHEV, one Classic, one Upgraded. To be the “range extender” on Ramcharger. Made in Trenton and Mexico.

Hemi. All variants likely to be made in Dundee, ramping up from August or September 2025 onwards.

Hurricane Six: Straight-six GME-based 3.0 liter engines with twin turbos made in Saltillo, Mexico. May be phased out or repurposed after Hemi ramps up, or switch places and become optional.

Hurricane Four: Next GME 2.0 four-cylinder, confusingly; closer to Hurricane Six than original GME; officially GME 2.0 EVO. To be made in Dundee if the project is completed.

GME. Global Medium Engine. 2.0T née “Tornado” and 3.0T “Hurricane” are turbocharged, developed by a team drawing from Chrysler, Fiat, and Fiat Brazil, using elements of the Neon engine, Pentastar and Hemi, and Fiat FIRE. 2.0 made in USA.

Belvidere started cranking out cars in 1965; in 1977, they switched over to front drive, making the Omni/Horizon and its derivatives into 1987. Starting in 1988 they went upscale with the Dynasty, New Yorker, Imperial, and Fifth Avenue, which they made until 1993. The first Neons rolled off the line in January 1994, and kept coming until 2005 until switching to Caliber, Patriot, and Compass; and finally Dart. Though Dart and 200 were on the same platform, Dart came from Belvidere and the 200 from Sterling Heights. Dart was replaced by Cherokee in 2017; Cherokee dropped in 2023.

This plant in the Bramalea section of Brampton, Ontario, has made the Chrysler 300, Dodge Challenger, and Dodge Charger for those cars’ entire lifespans (not counting the original 300, Challenger, or Charger); it was also sole home of the Dodge Magnum.

Built as “Bramalea” (the name of the development it’s in), the Brampton plant was put up by AMC just before Chrysler bought the company. It made the Eagle Premier, an AMC-developed version of a Renault which did not live up to expectations, from 1986 to 1992, joined after a time by the Dodge Monaco (a badge engineered car). From 1992 onwards, they made Chrysler’s large cars—the LH series until 2004, then the LX and related models, including the Lancia Thema.

The former spark plug factory that went on to build Vipers is now home to part of Chrysler’s car collection, and is used for meetings and education.

The Detroit Assembly Complex is three different factories. Two engine plants at by the Jefferson Avenue assembly plant, which has always made Jeep Grand Cherokees; the Conner Avenue plant down the road a bit made Vipers and is now an event center and internal museum. The original Mack Avenue Plant was created by Briggs Body; a second, dubbed Mack II, was made by Chrysler for engines. At their end, both were engine plants. They were joined into one to make the Grand Cherokee.

The original Jefferson Avenue plant had been built by Chalmers in 1909, and taken over by Chrysler in 1925. It closed in 1991; nearby, a new Jefferson North plant was put up in 1993. The plan was to close this factory but it might be revived for STLA Large due to import taxes in 2026.There are two plants in Toledo, the South one making Gladiators (originally also making Wranglers), and the North plant making Wranglers. These are new and surrounded by a supplier park. Toledo North was created to make the Jeep Liberty which started up in 2001; Nitro was added in 2014. They were replaced by the new KL Cherokee, and in 2017 by the Jeep Wrangler, with Cherokee moving to Belvidere. Toledo South has always made Wranglers or Gladiators, since being built in 1986 to replace the old Willys plant in Toledo.

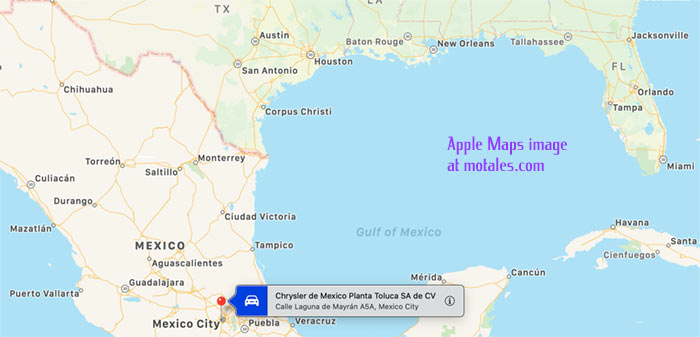

Makes the Wagoneer S and supposedly to make Recon and Cherokee. Built in the 1960s to supply Mexico, and called “AutoMex;” in 1978, Chrysler was the biggest seller of cars and of trucks in Mexico. In 1984 Chrysler adapted the plant to make K-cars, possibly the first time Toluca made vehicles for export to the United States rather than supplying the local market. It made offshoots of the K from 1987 to 1994, when it went to Neons and was the only home of two-door Neons. The PT Cruiser displaced Neons in 2001; Journeys joined the line in 2008 and stayed on until their end. Fiat 500 was added in 2011, leaving in 2017. The Toluca plant is the furthest still-active former-Chrysler factory from Detroit—Saltillo is close to the border.

Toluca was reportedly one of DaimlerChrysler’s highest-quality plants. The complex includes a stamping facility.

The 1968 annual report was the first we found to mention the Toluca factory. It stated: “Fabricas Automex S.A., in which Chrysler Corporation has a one-third interest, had record sales in 1968 of 29,799, as compared to 29,304 in 1967. In late 1968, a new 642,000 square foot assembly plant was dedicated at Toluca, near Mexico City. The Mexican company produces Valiant, Barracuda, Dart, Belvedere and Coronet cars, and Dodge trucks. It is the largest producer of Chrysler Corporation products in Latin America, with 1,348,000 square feet of floor space and 4,850 employees.”

A historic plant which has been expanded numerous times and gutted several times since 1980, Windsor is a modern plant using a flexible pallette system which raises and lowers vehicles as needed. Windsor makes all of Chrysler’s minivans, as it did in 1984, and is also making Dodge Chargers and other STLA Large vehicles in future. The Windsor complex used to have five separate facilities pumping out cars, trucks, and engines, but it’s all come down to one factory. The last of the older facilities, at Pillette Road, made vans. For a full history of Windsor, see our pictorials.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky