(Except pre-Mopar AMC/Jeep engines)

History and goal. Even before World War II, Ford had great success with their V8; it was less powerful than Plymouth’s six-cylinder, but it sold cars. Even after World War II, though, Chrysler Engineering chief Fred Zeder opposed dropping their fine straight-eight for a V8. Bill Drinkard and John Platner pointed out that a V design, with twin banks of four cylinders, would allow smaller engine bays and bigger bores, which meant bigger valves and higher performance. Powerplant chief James Zeder was convinced and went to his older brother, and either he or the president of the company finally authorized Chrysler’s (and Maxwell-Chalmers’) first-ever V engine.

Chrysler experimented to find the best design, testing every existing combustion chamber design on single-cylinder engines. They chose hemispherical heads for their power, ability to run on low-octane fuel, and long valve life, but there was a reason few automakers used hemispherical heads: they needed costly, complex twin cams. Chrysler came up with a clever single-cam design which used twin rocker shafts at each cylinder; these first “Hemis” were then nicknamed “dual rockers” after the twin shafts. Plugs were in the center of the chamber.

Over time, displacements increased from the original 331 cubic inches to 392. Chrysler/Imperial, Dodge, and DeSoto shared few if any parts, though their engines were all designed by Fred Shrimpton.

Identification. Production “original Hemis” have massive heads; spark plugs were protected by a ceramic boot, and inserted through a steel tube going through the valve cover. A second cover protected the tubes and spark plug wires; the latter are completely hidden from view. Distributors were in the rear of the engine and the valley of the V was covered by a panel.

The Hemi had stunning power for its displacement, and was the first V8 engine to ever produce one brake horsepower per cubic inch; but it was expensive and slow to make, and despite its maximum displacement of 392 cubic inches, it was quite large. The Hemi was launched on the 1951 Chryslers and Imperials; its final use was in the 1959 Dodge pickups, just a few years later. Along the way it made a name for Chrysler in European exotic cars such as Bristol and Facel Vega. Much more at the Original Hemi page.

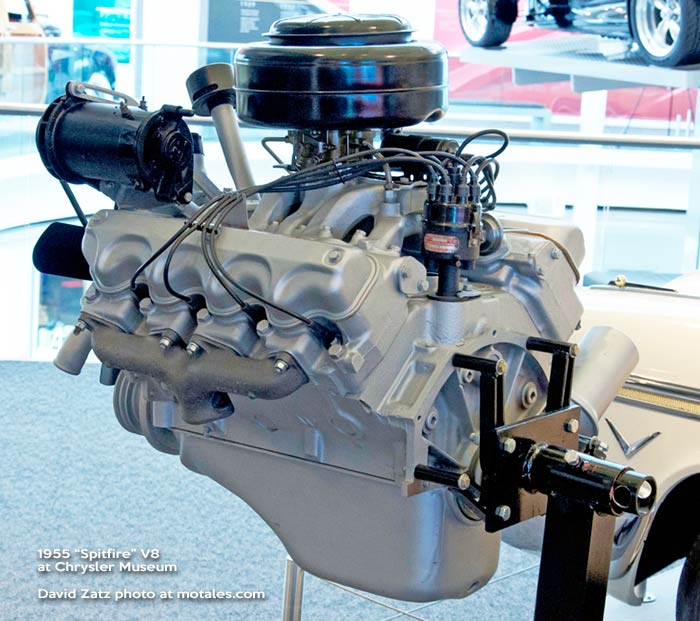

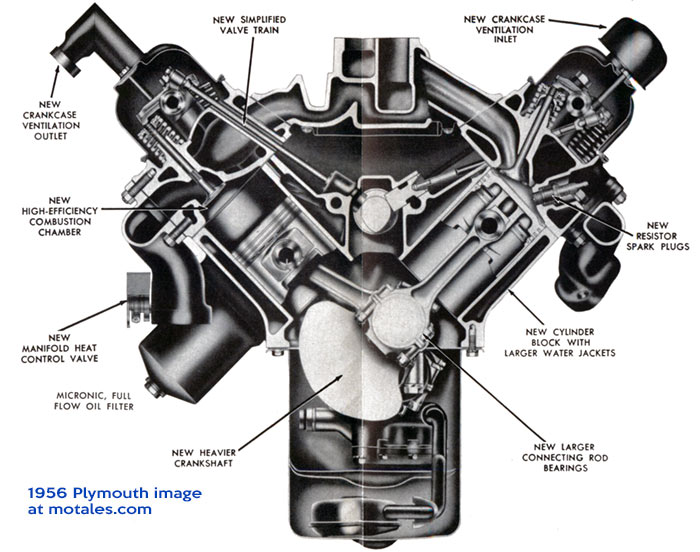

The company unexpectedly found they needed more powerful engines for their mainstream cars. Engineers created a Hemi V6, which did nothing to solve cost, complexity, and production speed issues. When this was rejected, they simplified their V8 design for higher production, creating the “poly” engines which debuted in the 1955 cars, with Dodge making engines for Plymouth. Hydraulic tappets meant the owners did not have to adjust the valves.

The combustion chambers were still rounded to avoid detonation and carbon deposits, but they were cast rather than machined. In addition, they saved eight rocker shafts per engine by having the top of the arm activate the intake valve and the bottom activate the exhaust valve! This engine still had big valves and a cross-flow arrangement. Some call it the “semi-hemi.” They were a temporary solution, used in the 1955 and 1956 cars and trucks. To save money they generally kept Hemi bores and strokes, other than the oddly small 241 and lack of a 392. James Zeder wrote, “We are not seeking to develop higher speeds and greater power than anyone else,” and the 241 wasn’t much more powerful than the old 260-cid six.

Identification. These engines look much like the Hemi, but with visible wires and scalloped valve covers to provide plug access. Distributors stayed in the rear of the engine. The V valley was covered by a plate. Heads were still quite wide.

The A series continued the Poly design, with changes made for easier manufacturing at the highly automated Mount Road engine plant. The Poly lasted from the 1956 to the 1967 model years, or in Canada, 1957 to 1968.

The A series had wider bore spacing and a higher deck than the poly so they could, in theory, expand beyond 392 cubic inches, but by the time that would have happened, Chrysler had its new B engines. The A did have resistor spark plugs to cut radio interference. Other tuning changes were moving the electrodes closer to the combustion chamber center and having larger valves and shorter pushrods and valve stems than the Poly. They used mechanical tappets to save money. Since the new plant had new tooling, they changed the bores and strokes. Dodge had a unique 325 engine they called the 326; otherwise, the divisions shared a 277, 301, 303, 313, and 318. All divisions shared the same engines other than the 325.

Identification. They kept the rear mounted distributors of the past series, and the scalloped valve covers of the Poly, but took out the V cover, using a bigger manifold to cover that space. The rocker pedestals were integrated into the head casting to cut costs; the timing chain cover was made of die-cast aluminum instead of cast iron. The oil filter was attached to the block instead of to an adapter; unlike the Poly, there was no shunt. Heads were still quite wide.

Much more on the A-series engines

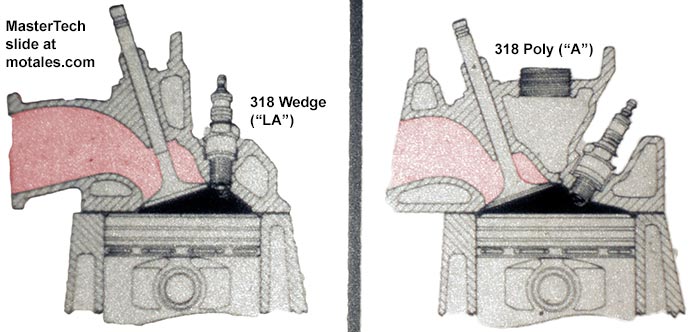

Company engineers re-examined their poly combustion chamber design and found that the polysphere added no performance gains. At the same time, the Indianapolis foundry developed a new process of casting blocks with much thinner walls; and thus the lightweight A engine was born. It had thin-wall blocks, cutting 50 pounds of weight; and wedge heads, cutting the size of the heads. They made as few changes as possible, overall, to cut tooling costs.

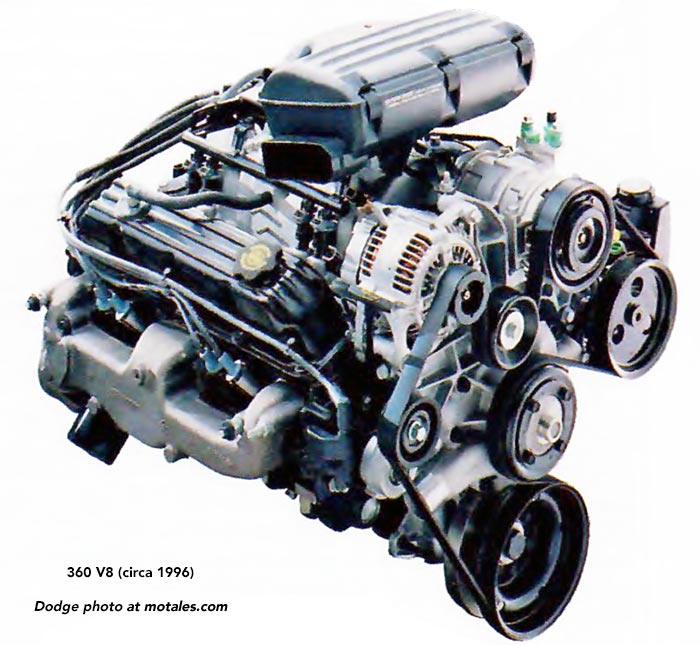

The LA arrived in 1964 and kept going into 2003, turning into a Magnum around 1993. From 1990 onwards it was only used in trucks and Jeeps.

Magnum versions of these engines used essentially the same block, but completely different heads equipped for sequential multiple-port fuel injection, with injectors in the manifold.

Identification. These V8s were made for many years with carburetors and fuel injection alike. The scallops in the valve covers are much smaller and the centers are not covered. The distributor is still in the left/rear area. The Magnum engines are easy to distinguish because of their multiple point fuel injection.

For much more, see our LA engines page and our Magnum engines page.

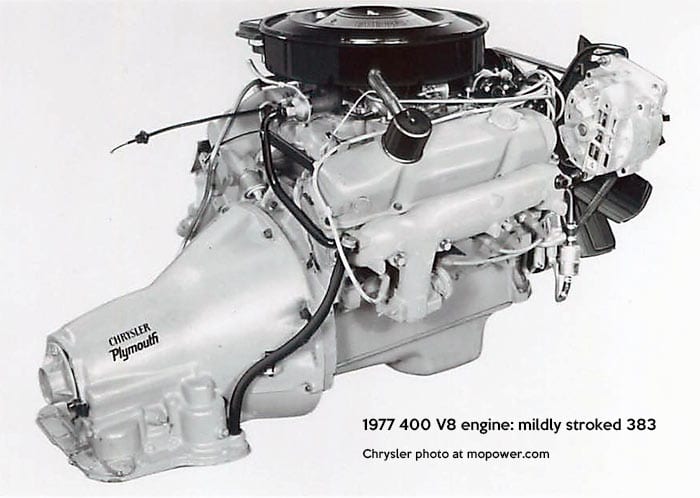

The B and RB series were created together, designed for cheap mass production with wedge heads and high automation. They were common to all divisions with no special-to-Chrysler-or-Dodge editions (other than a single-year Road Runner special 383 and a short-run Chrysler special RB 383). The energetic, skilled Robert S. Rarey led development, while Fred Shrimpton and Ray Latham created the block, with the biggest bore spacing (4.8 inches) ever used by Chrysler. They started with a modest 350 cubic inches. The long-stroke RB series had a raised deck for durability; the two series were designed to have as many parts in common as possible. It took just about two years to design the first engines, an incredibly short time given its success; it took the same team about the same time to make the slant six.

The B engine launched in the 1958 cars and trucks with small 350 and 361 cubic inch engines; the 350 was quickly dropped while the 361 carried on for many years, moving to truck duty after being dropped from cars. Tuning differences gave the engines rather different power ratings in the early years; marketing may also have lent a hand. They had different names by brand—Plymouth Golden Commando and Sonoramic Commando; Dodge Super Red Ram and D-500 (both also applied to Hemis); and DeSoto, TurboFlash. Sometimes the names were on the valve covers. The 383 came in the 1959 cars.

The most powerful RB engine was the 426 Hemi, which replaced the wedge heads with hemispherical heads. The huge heads brought the nickname “elephant engine” and made them easy to distinguish from any other RB engine. These are highly prized, essentially hand-assembled engines which could raise the cost of a car by 25%. Relatively few were ever made, and most of those were likely used for racing.

Lean Burn, originally a spark timing system, arrived for the B engines in the late 1970s; many have been converted to normal spark timing, but they are easy to identify by the control box if left stock.

The final engines in both series were built in late 1978, and the last Dodge pickup using one was made in 1979; but thousands of engines were stockpiled for slow sale to mobile home builders for many years afterwards. The 383 was probably the most popular version—three million were made.

| 350 | 361 | 383 | 400 | |

|---|---|---|---|---|

| Bore | 4.06 | 4.12 | 4.25 | 4.34 |

Identification. The oil pump was moved to the front bottom left of the block, and the distributor moved to the front top right, away from ventilation gear. The oil pump’s aluminum cover doubled as an oil filter mount.

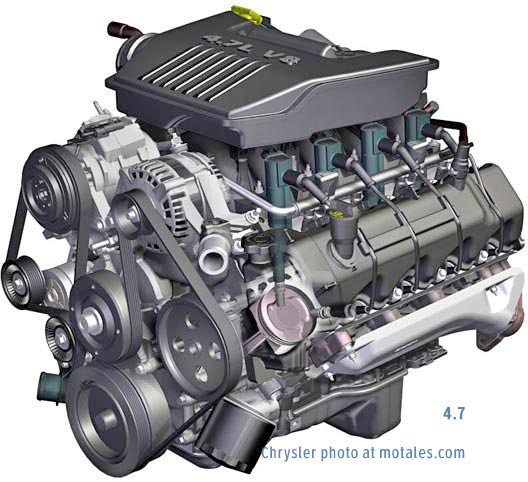

The next truly new V8 engine (Chrysler’s third so far) arrived at the urging of new head of engineering Francois Castaing, who felt the existing V8s were somewhat dated—their basic design going back to 1951. Bob Lees was in charge of the new program; he considered a four valve per cylinder design, but ended up sticking to two valves to get low-revolution torque and low cost. This engine had a plastic intake manifold with a perfectly smooth, precise surface. The “Corsair” or “Next Generation” 4.7 was first used in the 1999 Jeeps, and phased in to replace the “5.2” (318) Magnum LA V8s. Nearly every dimension was different.

A High Output version came next, with domed pistons raising compression. Flex fuel versions arrived with the 2004 fleet trucks and 2007 retail trucks. The 2005 version had dual knock sensors, new calibrations, and many other changes; these were the first with EGR. A thorough redesign of the top end arrived after the Hemi V8 was developed, moving to two plugs per cylinder and slant-squish heads; these and many other changes dramatically increased power, from 230 to over 300 hp. The two plugs per cylinder are a dead giveaway of this generation.

Identification. The cooling system was an industry first, using in-line engine-driven and electrical fans; it was unique to Chrysler V8s, too. If the cover is missing, that is one indication of the engine type. The basic shape and design is hard to miss. The revised “Hemi-style” version is obvious from the dual spark plugs per cylinder.

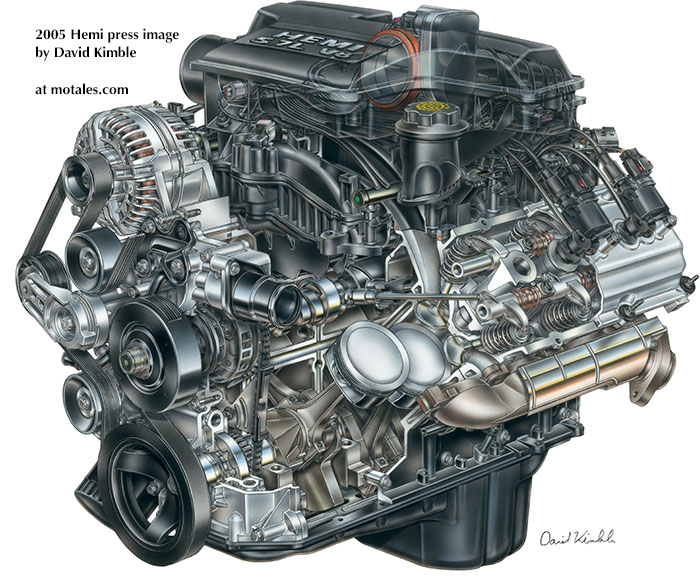

The mainstream Hemi V8 has always had the same displacement of 5.7 liters, from its 2004 launch in Ram pickups to its final days—21 years in production, since the factory (Saltillo) started making Hemis in 2002. As with the Next Generation V8, the Hemi was spurred into being by Francois Castaing. It was a completely new design, despite the recent successful launch of the 4.7.

At launch, in the 2004 Ram 1500, the new “Eagle” project delivered 345 horsepower at 5,600 rpm and 375 lb-ft of torque (4,400 rpm), one net horsepower per cubic inch—well out of the old 360’s league. Several versions differed mainly in their air path and tuning; the Dodge Charger had slightly lower horsepower but more torque than the Ram 1500. In cars, the new V8 had a “multiple displacement system” (MDS) which shut off fuel to four cylinders when less power was called for. It made a difference.

Despite the semi-hemispherical-head design and far greater power, the new V8 was cheaper than the old LA series 360 V8 it replaced. It was reputedly even cheaper than the “Next Generation” 4.7 V8 designed by the same team. The original Hemi had been far too expensive and hard to build, but automation, advances in materials, new valvegear designs, and greater precision in automated equipment all helped. The major problem was meeting emissions rules; Willem Weertman, the legendary engine designer, was brought back to consult, contributing among other advice the idea of having two spark plugs per piston.

The meaty deep-skirt cast iron block was ideal for durability. The iron block was mated to aluminum heads and a plastic intake manifold. Like the original Hemi, it had dual rocker shafts; valve sizes and locations were similar to the 426 Hemi. Its 345 cubic inch displacement matched that of the Hemi V8 in the 1957 DeSoto Adventurer, the first standard V8 to have one brake horsepower per cubic inch. It also used pushrods for the overhead valves.

Production began in June 2002 at the Saltillo plant in Mexico—the home of every modern V8. It was unveiled in Ram trucks in December 2002. The first supercharged engine was shown to the public in January 2003, in the Magnum SRT-8 and 300C concepts; but buyers would have to wait many years to actually buy a supercharged Hemi. The “take rate” hit 45% across every verhicle where it was optional. Still, the new Hemi was one of the few new engines of its era lacking variable valve timing.

Each cylinder had a coil pack over one spark plug, while the other had a wire running to a coil pack on the other side of the engine. Each coil pack fired both its own plug and a plug on the other bank of cylinders. That allowed for the dual-sparks system and strong primary sparks without doubling the number of coils to 16.

The second generation “Eagle” 5.7 Hemi had a clever hydraulic cam phasing system; by moving the cam slightly, valve timing and lift was optimized for idle, low power, or high power. The camshaft (as before, a hydraulic roller setup) had oil passages to drive the cam phaser sprocket. Engineers also boosted compression and improved airflow, and added an active intake manifold with dual runner lengths. Other changes were more technical, but reached most of the engine parts. Both truck and car versions had MDS.

The published horsepower ratings of the little 5.7 were actually higher than net horsepower for the famed 426 Hemi. The engine was a tremendous success, and the 4.7 V8 was dropped even after a “Hemi-style” head and valvetrain redesign gave it more power. There was just no point, with the Eagle providing similar gas mileage and much higher performance at the same (some said lower!) cost.

Owner guidance is on our main 5.7 Hemi page.

The 6.1 Hemi was created for the SRT-8 series—Magnum, 300C, Charger, and later Challenger and Grand Cherokee. The addition of the 6.1 repositioned the 5.7 Hemi somewhat as a more mainstream engine despite its still quite high power output. It launched in 2004 and lasted through to 2010, replaced in the 2011 cars by the “392” (6.4 liter). The latter was deliberately sized to match the biggest and most powerful Original Hemi V8.

The SRT engine was not just a bored-out, high-compression 5.7 (though it was bored out by 3.5mm). For durability, it had reinforced bulkheads, oil squirters aimed at the underside of each piston, a modified oil pan and windage tray, flat-top high-load pistons, powdered-metal rods, forged crank and retuned damper, sodium-filled exhasut valves, and other upgrades. For performance it had larger cross-sectional area in the ports, larger valves with special damped valve springs, new manifolds and exhaust with higher airflow, and dual knock sensors. Both 6.1 and 6.4 required premium fuel.

With its stunning 425 hp and 420 lb-ft of torque, the 6.1 easily beat the legendary 426 Hemi in power and torque alike; it matched the brake horsepower of the 426. Quarter-mile times showed that it was indeed far ahead of the Hemi-topped RB engine of the 1960s and early 1970s, the Mopar man’s emblem of muscle. It managed double-digit highway mileage and was both durable and reliable, needing no tuning thanks to the computer-controlled timing and fuel delivery; and it didn’t drink oil like its predecessor. What’s more, the 6.1 provided essentially “instant-on” torque from any engine speed, with a surprisingly high torque rating even at idle. This was the engine for people who wanted immediate action when they pressed the gas, with no need to wait for downshifts or higher revs. More on the 6.1 SRT Hemi V8

The 2011 and newer SRT8 cars, including a Jeep Grand Cherokee, used the new “392” engine displacing 6.4 liters; this was the first Hemi engine with cylinder deactivation, which meant highway mileage was far better (MDS was not used with manual transmissions, which were also limited to 410 lb-ft of torque). Power was surprisingly high—475 hp and 460 lb-ft at launch in the 2011 Challenger, then 465 hp and 465 lb-ft in the 2012 Challenger, and finally, in the 2015 Challenger, 485 hp and 475 lb-ft. This was far higher than the 426, even when comparing net to gross figures. As with the 6.1, it had dual spark plugs. EPA gas mileage was actually better than the 6.1 liter engine.

Full 6.4 page in progress.

A truck 6.4 followed the SRT version; launched in the 2014 Ram 2500 and 3500, it was created for durability and low-end torque more than for ultimate power. It ran on 89 octane gasoline rather than 91 octane, and generated 410 hp and 429 lb-ft of torque—or, on certain chassis cabs, 367 hp and 429 lb-ft of torque. It too had an active dual runner length intake manifold and sodium-filled valves, but also had a high-volume oil cooler and cooled EGR. The deep-skirt design used a cast iron block and 356 aluminum heads. MDS and twin plugs for each cylinder were also common with the other Hemis. This engine was quite reliable, with no known major issues. It remains in production. Motales 6.4 page in progress.

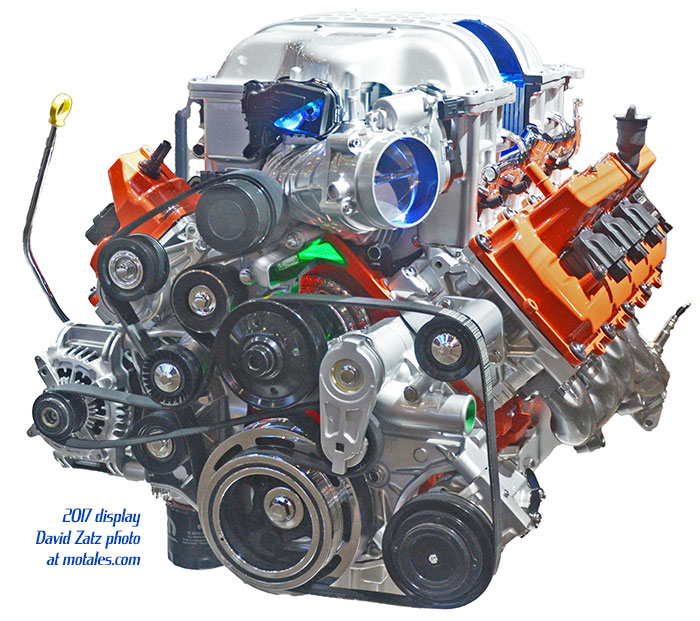

The Hellcat engines were launched with the 2015 Dodge Challenger and Charger. Their 707 horsepower output was stunning at that time; their 650 lb-ft torque output was also incredible. It was based on the 392, with a massive supercharger, but that was not all: it needed a new block, heads, crank, rods, pistons, front cover, crank damper, oil and water pump. When launched, it had the highest output of any engine from a mainstream American automaker. It was developed in-house, and made the Charger Hellcat into the fastest production four-door sedan, reaching 204 mph. It generated 411 lb-ft of torque at just 1,200 rpm—more torque than the 5.7’s peak. The gross horsepower rating, which would compare to the 426 Hemi’s 425 bhp, was over 800 bhp.

The supercharger is a dead giveaway for identification, but the block, heads, and covers were also powder-coated to glossy orange.

Later versions of this stunning engine would produce 840 hp on racing fuel in the Dodge Challenger Demon, then 808 hp on ordinary 93 octane fuel in Redeye and Widebody cars, and eventually 1,025 hp in the Dodge Challenger Demon 170—a car still legal to drive on the street. This version eschewed the orange powder coating but also has a distinctive look of its own.

For far more detail, see the Motales story on the Hellcat V8.

Casting numbers on vintage cars were usually seven digits long, stampled on the top of the intake runner under the valve cover, or under the intake runner on the head. Other identification cues are in each engine’s section.

Original Hemi

| Year | Gross Horsepower and Torque |

|---|---|

| 331 Chrysler FirePower | |

| 1951-53 | 180 hp / 312 lb-ft |

| 1954 | 235 hp |

| 1955-56 | 250 hp |

| 1956 | 300 hp / 345 lb-ft (C300) |

| 354 Chrysler FirePower | |

| 1956-57 | 280 hp / 380 lb-ft |

| 1956 | 340 hp / 385 lb-ft (300B) |

| 1957 | 340 hp / 380 lb-ft (Dodge D-501) |

| 1957 | 295 hp |

| 1957-59 | Dodge pickups |

| 1956 | 355 hp (300B option) |

| 392 Chrysler FirePower | |

| 1957 | 325 hp (375 hp, 420 lb-ft in 300C) |

| 1958 | 290 hp |

| 1958 | 310 hp |

| 1958 | 345 hp |

| 1958 | 380 hp (2 x 4 bbl), 435 lb-ft |

| 1958 | 390 hp (EFI), 435 lb-ft |

| 1958 | 360 hp (Facel Vega) |

| Dodge Red Ram and Super Red Ram | |

| 1953-4 (241) | 140 hp / 220 lb-ft |

| 1955 (270) | 183 hp (245 lb-ft) or 193 hp (with Power Pack) |

| 1956 D500 (315) |

260 hp / 330 lb-ft (D500) 295 hp (D500-1) |

| 1957 D500 (325) |

285 hp / 345 lb-ft 310 hp / 350 lb-ft |

| DeSoto Fire Dome | |

| 1952-54 (276) |

160 hp / 250 lb-ft |

| 1955 (291) | 200 bhp / 274 lb-ft 185 bhp / 245 lb-ft |

| 1957 (341) | 270 hp / 350 lb-ft |

| DeSoto FireFlite | |

| 1956 (330) | 230 hp (255 w/4bbl) / 305 lb-ft |

| 1957 (341) | 295 hp (4-barrel) / 375 lb-ft |

| DeSoto Adventurer | |

| 1956 (341) | 320 hp / 356 lb-ft |

| 1957 (345) | 345 hp / 355 lb-ft* |

Poly

| Size | Bore | Stroke | Hemi Max BHP | Poly Max BHP |

|---|---|---|---|---|

| 241 | 3.4375 | 3.25 | 140 | 157 |

| “260” | 3.56 | 3.25 | - | 175 |

| “270” | 3.625 | 3.25 | 193 | 189 |

| 301 | 3.625 | 3.625 | - | 188 |

| 315 | 3.625 | 3.8 | 295 | 230 |

| 325 | 3.69 | 3.8 | 310 | 265 |

| 331 | 3.81 | 3.63 | 300 | 225 |

| 354 | 3.94 | 3.625 | 355 | 310 |

A

| Engine | Years | Bore | Stroke |

|---|---|---|---|

| 277 | 1956-57 | 3.75 | 3.125 |

| 301 | 1957 | 3.9 | 3.125 |

| 303 | 1956-57 | 3.81 | 3.31 |

| 313 | 1957-64 | 3.88 | 3.31 |

| 318 | 1957-68 | 3.91 | 3.31 |

| 326 | 1959 | 3.95 | 3.31 |

LA: 273, 318, 340, 360, 355 racing engine

| 1994 | Trucks |

horsepower |

torque |

| 3.9 V6 | Dakota, B-Van | 175@4800 | 225@3200 |

|---|---|---|---|

| 3.9 V6 | Ram Pickup | 175@4800 | 230@3200 |

| 5.2 | Dakota, B-Van | 220@4400 | 295@3200 |

| 5.2 | Grand Cherokee | 220@4800 | 285@3600 |

| 5.2 | Ram Pickup | 220@4400 | 300@3200 |

| 5.9 | Ram 1500, 2500 B-Van |

230@4000 | 330@3200 |

| 5.9 | Dodge Ram 3500 | 230@4000 | 330@2800 |

Next Generation

| 2005 (Durango) | 4.7 | 4.7 H.O. |

|---|---|---|

| Horsepower | 235 | 270 |

| Torque | 295 | 330 |

| Compression | 9.0:1 | 9.7:1 |

| Intake open and close |

4.4° 239.1° |

3.0° 233° |

| Exhaust open /close |

240.5° 13.2° |

235° 15° |

| Valve overlap | 17.6° | 18.0° |

New Hemi

| 5.7 | 2004 Ram | 2005 Charger | 2009 Ram | 1971 426 |

|---|---|---|---|---|

| mpg | 14/18 | 15/23 | 13/19 | n/a |

| Hp. | 345 | 340 | 390 | 350 |

| Torque | 375 | 390 | 407 | 390 |

SRT and trucks: 6.1 and 392 Hemi

| 6.1 SRT8 | 6.4 (392) | |

|---|---|---|

| Horsepower | 425 @ 6,000 | 470-485 |

| Torque | 420 @ 4,800* | 460-475 |

| EPA mpg | 13/18 | 14-15/23 |

| 2014 Specs | Truck 5.7 | 6.4 Truck I |

|---|---|---|

| Compression | 10.5:1 | 10.0:1 |

| Max revs | 5,800 rpm | 5,800 rpm / 4,660 with Aisin |

| Oil capacity | 7.0 quarts | 7.0 quarts (6.62 liters) |

| Coolant | 18 quarts | 15.75 quarts (15 liters) |

Sources: Willem Weertman, Chrysler Engines, SAE; Allpar.com; Press kits, 1998-on; Kevin Haddock on allpar; other Motales features.

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky