Chrysler’s first V8 engines were meant for high-end cars, mixing relatively small displacements with efficient, high-flow hemispherical heads. The company needed to step up its ordinary-engine game, though, and after just four years started making cheaper “poly” engines with simplified valvegear and heads. Then Chevrolet launched their own V8, and Chrysler realized they had not gone far enough; they started two new projects—one to create cheap big-block engines (B and RB), and one to mass-produce cheaper V8s based on the poly series. These, dubbed the A series, were also engineered for a much higher degree of automation in the state-of-the-art Mount Road engine plant—and they would be made from 1956 through 1967.

Mound Road itself had been built for World War II, and according to Willem Weertman, when they started converting it to engine production, a some leftover aircraft assemblies—tails and fuselage sections—were “scattered about the plant floor.” But it would be outfitted as a thoroughly modern facility.

This may have been the last engine Mel Carpentier worked on; he had worked alongside “the Three Musketeers” at Studebaker, then at Willys, and finally at Maxwell / Chrysler, and had his hands in every Chrysler engine to this point.

As the A-series was finalized, a new centralized engine division was formed to design and build engines, and supply them to the car and truck divisions, dramatically reducing the absurd complexity which had arisen.

The new engine block was based on that of the Hemi V8, but with expanded bore centerline spacing (to 4.46 inches) and a higher deck (9.6 inches) for future growth—though the biggest Hemi was 392 cubic inches, and the biggest A-series engine, if one includes the later LA, was only 360 cubic inches. Bigger engines than that were built on the new B and RB architecture. The “A series” moniker itself came about when engineers were talking about the A479 (American version) and A514 (Canadian version) programs together—but it was a handy way to refer to this new group of lighter, cheaper, and ultimately more powerful engines.

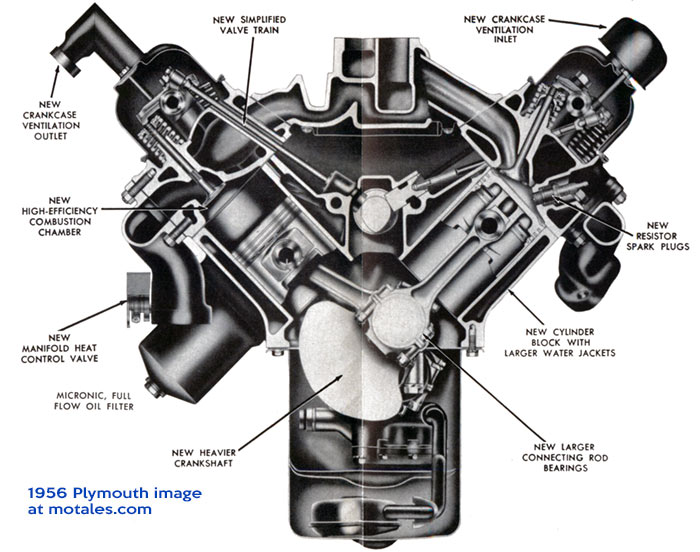

Both poly and A series had, like the Hemi on which they were based, rear-mounted distributors. The poly had scalloped valve covers, to make it easier to replace spark plugs, which the Hemi series did not; the A engines had these scalloped valve covers as well. The Hemi and poly series had a cover for the “valley” between the cylinder banks, while the A-engines, to save money, simply used a bigger manifold to cover that space (which they promoted as providing higher performance). The A series integrated its rocker pedestals into the head casting to cut costs further, while reducing weight by using die-cast aluminum instead of cast iron for the timing chain cover and, later, for the water pump body. The crankshaft was enlarged and strengthened for long-term durability.

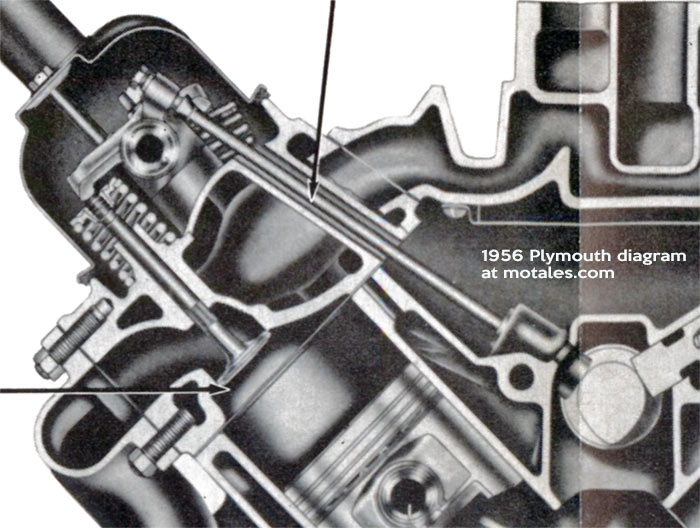

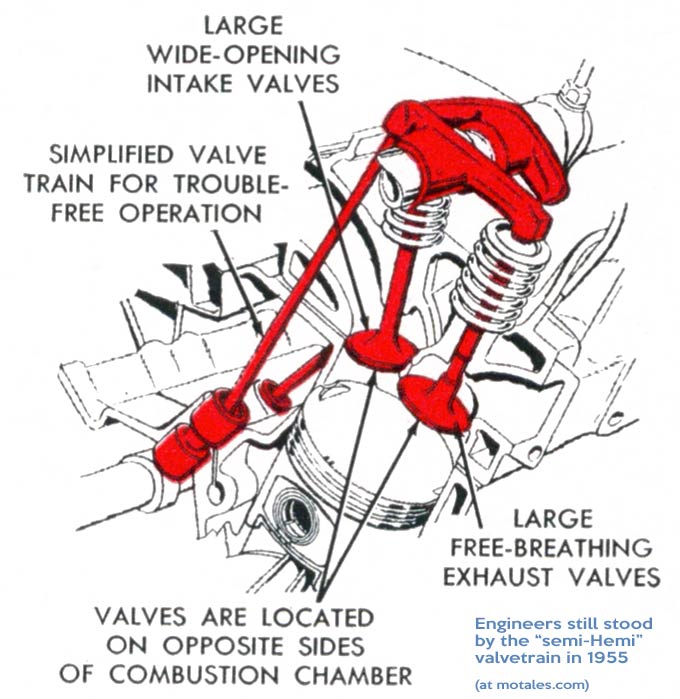

The A engines are generally not called “poly,” but had polyspherical heads. Engineers believed that the “poly” design, which its valves on opposing sides of the chamber and more central spark plugs, was a major advantage over V8s where valves were “squeezed alongside each other on one side of the chamber;” they also felt that the rounded combustion chamber reduced detonation and carbon hot spots and credited the design with allowing the use of regular fuel rather than premium. The crankshaft, rods, and pistons were all similar to (but not interchangeable with) the poly series; the cam was redesigned to have “quieting ramps.”

The A series combustion chamber kept the rounded “poly” design, but there were some changes. Engineers specified resistor spark plugs (possibly to reduce radio interference) and moved the spark plug electrodes closer to the center of the combustion chamber. Valves were enlarged for better breathing, and the pushrods and valve stems were shortened. The technician’s guide claimed that allowed the company to move to mechanical tappets, but the reality was more likely that mechanical tappets are cheaper and easier to make and install. Now, the valves had to be adjusted periodically using self-locking screws at the end of the rocker arms.

While the poly engines generally shared their bore and stroke with the Hemi series, the A engines did not; the automated equipment and Mount Road was all new and never used for making poly or Hemi engines, so sharing bore and stroke would not have saved any money.

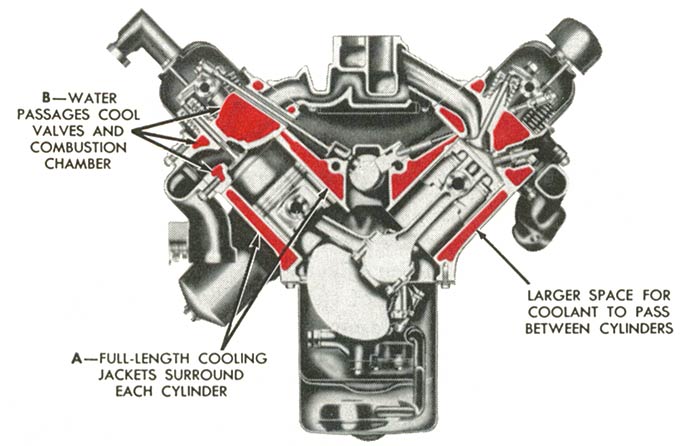

The A series also replaced 16 drilled oil feed holes with two oil galleries drilled into the block to the the tappet bores, and replaced the oil filter adapter by attaching the filter directly to the block; and a full-flow replaceable oil filter replaced the polys’ shunted oil filter with replaceable elements. Engine cooling was addressed with full-length water jackets completely surrounding each cylinder, and the block, as noted before, had more space between the bores.

Overall, Chrysler engineers did a surprisingly thorough job of reworking the lubrication and cooling systems of their existing engines, simplifying the valvetrain, and planning for future power needs. At this time, of course, they did not know they would be creating a completely new line of bigger engines as well.

Regardless of which engine series they used, 1956 cars had new automatic choke carburetors controlled by a bi-metal coil; and a manifold heat control, which used a similar technology to warm the carburetor from startup for better fuel vaporization. The company also switched from six to 12 volt electrical systems in this year, which meant new coils, distributors (with single sets of breaker points rather than dual points), voltage regulators, batteries, generators, plugs, headlights, and starters.

The 1956 Plymouths were the first cars with A engines—advertised as 277s, but actually displacing 276 cubic inches. This was a bit larger than the V8 Poly which Dodge was already making for Plymouth. Plymouth used the Hy-Fire name for both types of engines, Poly and A, and continued to call the four-barrel carburetor option—which boosted horsepower to 200—the “Hy-Fire with PowerPak.” The Poly, with six (or seven) fewer cubic inches, was put into the low-end Plaza and Savoy, while the new A-type 277 (ironically cheaper to make) was in the higher-end Belvedere and Suburban. A service bulletin of the time claimed that there was more to the story than peak power ratings—the new V8, it said, had higher torque at low revolutions, providing better pickup for passing or accelerating from stoplights. That was likely true; and it was also easier to work on.

| 1956 | 270 | 277 | 277 | 303 | 303 |

|---|---|---|---|---|---|

| Type | Poly | A | |||

| Bore | 3.63 | 3.75 | 3.8125 | ||

| Stroke | 3.256 | 3.13 | 3.3125 | ||

| BHP | 180 | 187 | 200 | 218 | 240 |

| Torque | 260 | 265 | 272 | 309 | 310 |

| Carb | 2V | 2V | 4V | 2V | 4V |

Chrysler Canada started making 303 cubic inch V8s in mid-1956, also with a choice of two and four barrel carburetors. These produced considerably more power than the 277 (or at least they were rated that way by the company), as befitted their use in the Canadian 1956 Dodge Custom Royal and Chrysler Windsor; they were also the standard V8 in the 118”-wheelbase 1957 Plymouth and Dodge cars.

Late in the year, Plymouth released the latest Fury, a specialty muscle car; with the Canadian 303, it set new records for the flying mile (124 mph) and standing-start mile (82.5 mph). The engineers also used a version with a Chrysler 300B intake and dual carburetors to reach 148 mph in the flying mile. The stock Fury 303 had a 9.25:1 compression, with fuel coming through a Carter WCFB 2442 S four-barrel carburetor; internals included reinforced dome pistons, hot camshaft, high-load springs, balanced rods, and special distributor.

For the newly facelifted 1957 cars, the 277 was uprated to 197 horsepower. The Canadian 303 was replaced in the United States by a bored-out version with 301 cubic inches—the rationale for designing a new engine that was so similar is unknown. The 301 (actually displacing 300 cid) had a choice of two and four barrel versions, again, with 215 and 235 hp ratings; Plymouth ads claimed at as new, which was fair enough, and “Bigger in every way. More power for safe response. Bigger displacement. A new, quieter camshaft. A new jet-flow carburetor.” For 1957, they also switched most vehicles from oil-bath air cleaners to modern replaceable paper air filters as the standard, making oil-bath air cleaners optional.

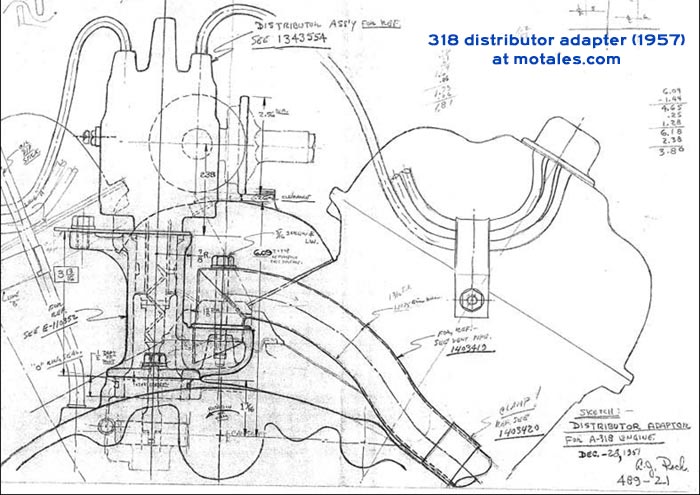

The 1957 Fury had a new engine, using the bore of the 301 and a larger stroke—the 318. With dual Carter WCFB four-barrel carburetors, it was rated at 290 horsepower and 325 pound-feet of torque, quite an improvement over the 1956 Fury engine. The 318 was only used in the Plymouth Fury for this year.

| 1957 | 277 | 301 | 301 | 318 |

|---|---|---|---|---|

| Carb | 2V | 2V | 4V | 2x4V |

| BHP | 197 | 215 | 235 | 230 |

| Torque | 270 | 285 | 340 | |

| Bore | 3.75 | 3.9 | 3.9 | |

| Stroke | 3.125 | 3.125 | 3 5/16 | |

| C/R | 8:1 | 8.5:1 | 9.25:1 | |

The smaller engines were dropped for the 1958 model year to simplify parts inventories. The 1958 cars and trucks had simpler choices than the insane 1952-57 model years: 230 six, 350 or 361 B V8, 392 Hemi V8, 318 A-V8, or one of the final poly V8s. The 277 and 301 were both dropped in favor of the 318, sold in three forms—two-barrel, four-barrel, and Fury carrying over with twin four-barrels.

| 1958 318 | BHP | Torque |

|---|---|---|

| 2-bbl | 225 | 330 |

| 4-bbl | 250 | 340 |

| 2x4-bbl | 290 | 330 |

For Canadian production, Windsor used a new bore size with the old stroke to create a 313 cubic inch version—their only V8 all the way into the 1964 model year. The reason why Canadian engines differed from the American series was likely to re-use existing tooling; Canada did not have a brand new plant for their A-series production.

The Canadian 313 engine was used by British exotic carmaker Bristol with a four barrel Carter carburetor and a 250 horsepower rating; it powered the Bristol 407 and most of the Bristol 408s (the last 18 Bristol 408s used a newer version of the engine). In Canada, the 313 debuted in the 1957 Dodge Custom Royal, then replaced the 303 as the standard V8 for the 1958 through 1964 midsized Plymouth and Dodge cars. (The Canadian 1958 Dodge Custom Royal moved to the poly version of the 354, as did the Canadian-built DeSoto Firedome and Chrysler Windsor; the 354 poly was replaced by the B-series V8s in 1959).

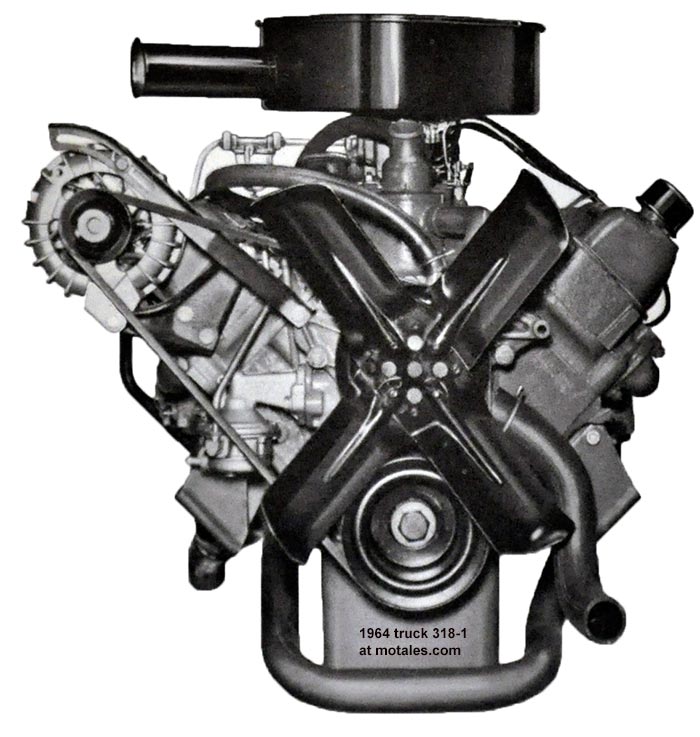

Inside or outside of Canada, truck versions of the A engines had lower horsepower ratings due to lower compression ratios, likely a durability measure. In 1964, for example, the truck 318’s rated output was 200 or 202 bhp and 286 or 288 lb-ft, with a 8.6:1 compression ratio instead of the car engines’ 9.0:1 compression. Truck engines had special valve coatings and valve rotators, and numerous materials and design changes for durability. The two-barrel rose from 225 to 230 hp in 1959, a rating it would keep all the way to its end (though the compression went up from 9.0:1 to 9.1:1 in 1962); torque remained steady at 340 lb-ft.

| 1962-66 318 | BHP | Torque |

|---|---|---|

| Truck | 200 or 202 | 286 or 288 |

| 2-barrel | 230 @ 4,400 | 340 @ 2,400 |

| Ford 292 | 185 | 292 |

| Chevy 283 | 170 | 274 |

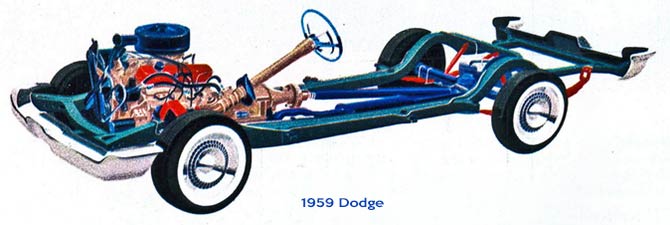

The last of the poly engines were used in the 1958 Dodge cars; from then on, Dodge and Plymouth both used the A-engines and, in their 1959 lineup, both divisions used both the A and B-engines. Dodge, though, demanded an engine that was larger than their 325 Poly; this brought the 326 cubic inch A-series V8, the only A engine with hydraulic valve lifters.

A bored-out 318, the 326 was rated at 255 hp and 350 pound-feet with a two-barrel carburetor. It was only “needed” for the 1959 Dodge cars, possibly because Dodge could not justify the higher cost. The chart above shows that the 318 was enough to deal with Ford and Chevy’s entry-level V8s.

The four-barrel version 318 went up to 260 hp in 1959, but it did not return for 1960, likely because its role was taken over by the new B-engines. The Dodge 326 was likewise not to return for 1960. From 1960 to 1964, Chrysler Canada kept making the 313, switching to the 318 in the 1965 model year.

The American A-type 318 was dropped in 1966, with the new LA-type 318 produced from the 1967 model-year onwards; in Canada, that switch occured one year later. That caused some confusion as cars made in Canada and exported to the United States, such as the 1967 Fury and Polara, used the A-series 318, confusing matters a little—but not as much as Chrysler keeping the 318 cubic inch displacement of the A series into the next generation of engines, the LA.

The engines were coded slightly differently. The 1967 A-series 318 (Canadian) is coded CC318, one C meaning 1967 and the other meaning Canada; the American LA-series 1967 318 was coded C318 (the one C meaning 1967).

The A series engines were the last with the poly head design; while hemispherical heads were still considered the best, further testing showed that the “poly” wasn’t any better than cheaper wedge designs. The engine blocks continued virtually unchanged into the LA series, though, being altered in the 1970s to create the 360. The heritage of the Hemi continued to stay in Chrysler’s more humble mass-production V8 engines all the way into the 20th century, as the LA design was adapted into V6 and V10 versions.

The original “poly” engines were only made from 1955 to 1958; the A series “poly” carried on from 1956 to 1968. There were only six varieties of the A series, two of them unique to Canada, thanks to the centralized engine group. The next step would be the LA—a major leap in some ways but a very minor one in others. These would carry on for much longer, making it into the modern era, and being the only classic Chrysler engines to be mass-produced with electronic fuel injection (not counting a few 1958 Electrojectors). Move on to the LA engines.

A-series V8 engines had 1.84” intake valves and 1.56” exhaust valves. The cam was chain-driven. The oil pump and distributor were both at the rear of the block. The next generation of engines, the LA series, only kept one of its displacements—318 cubic inches—dropping the 277, 301, 303, 313, and 326.

| Engine | Years | Bore | Stroke |

|---|---|---|---|

| 277 | 1956-57 | 3.75 | 3.125 |

| 301 | 1957 | 3.9 | 3.125 |

| 303 | 1956-57 | 3.81 | 3.31 |

| 313 | 1957-64 | 3.88 | 3.31 |

| 318 | 1957-68 | 3.91 | 3.31 |

| 326 | 1959 | 3.95 | 3.31 |

Italy slaps Elkanns’ wrists in tax case

See how Jeep, Dodge, Ram, Chrysler do on new quality-vs-cost chart

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky