Chrysler made Leece-Neville alternators optional starting with their 1950 taxi and police cars, but didn’t use them in regular cars. Alternators were better than generators in some ways—charging at idle, longer lifespan, and higher output—but they were more expensive, bigger, and pulsed at idle when hooked up to mechanical voltage regulators.

Chrysler had a fine electronics division, though, which developed an electromechanical voltage regulator. Then Glenn S. Farison invented a method for converting three-phase AC to DC through silicon diode rectifiers. Other diodes in his design made the circuit one-way—the battery wouldn’t turn the alternator into an electric motor!

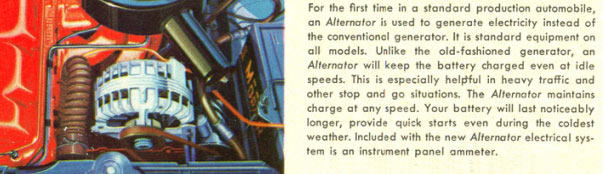

The invention made Chrysler the first automaker with standard alternators, starting with the 1960 Valiant. Their new alternator, the first to use diodes to convert power in a car, ran up to 60% of its peak capacity while the engine was idling, and eliminated the commutator, rotating armature, and current carrying arcs. It was smaller, lighter, and cheaper than the Leece-Neville units.

Chrysler made its alternators in Indianapolis; Essex Wire Corporation in Detroit, which supplied the wire and components, may have made some alternators. (Founded in 1930, Essex was taken over by Superior Telecom and became Superior Essex in 1998.)

Alternators need the battery to be connected at all times because without the battery, the voltage fluctuates too much and can blow out the car’s electrical system.

The aluminum alternator case should not be cleaned with sandpaper or wire brushes, but by a soft brush and mineral spirits. Castings of rebuilt alternators are often hard to read due to the harsh cleaning process.

Lester suppied many castings for Chrysler alternator housings until 1965, stamping them just with their logo, the Forward Look rocket logo, and the casting number (2095191 or 2095192). They may still have date codes stamped as “date wheels” or pies stamped on the alternator housing, as Mopar’s own alternators did. In the middle was the year; around the circle, a dot showed the week within the month. Each section within the wheel was a month.

In 1972, Chrysler started stamping the part number and build date on a tag instead, though the housing still showed the build date. Round-back alternators have their date and part number cast in on a boss below the battery terminal. The date is a two-digit week and two-digit year, usually stamped underneath the seven-digit part number; more numbers may also be stamped there.

The alternator usually had date-coded diodes as well—four digits, the first three for the day (e.g. 225 for the 225th day of the year) and the final number for the year.

A generator turns motion to electricity, using principles discovered by Michael Faraday. They were not practical for much of the 19th century; electrical current was mainly made by chemical batteries, which had to be regularly refreshed. Thomas Edison, realizing that current electrical theory was wrong, created the first efficient generators in the 1880s, before Nikolai Tesla got his first job.

Generators use a turning armature (a wire wound around a metal reel) with a set of brushes; the brushes carry all the current, which generates heat and limits their output. When the brushes pass over the commutator (a rotary electrical switch), sparks shortened their life; hard brushes lasted longer but wore out the commutator faster.

Generators and alternators both need a way to cut power when they are not charging; otherwise the battery would turn them like an electric motor. Generators use a cutout relay for this, while Chrysler developed a diode set for the same purpose.

Alternators use field coils wound around a large bobbin, surrounded by iron shells. The rotating assembly (rotor) spins within a wire wound around a steel core (the stator). Alternators create alternating current, because the field alternates between the poles rapidly; the current is converted by the rectifier—the diode assembly—into direct current, which the car can use.

STLA euroshare edging up as EVs, hybrids gained

New Compass now made at Melfi (Italy)

STLA jumps into robotaxis with Uber, Nvidia, Foxconn

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos