The first Dodge Durango was based on the highly successful Dakota pickup, and hit the ground running; the remake under Daimler was disastrous, and the final recipe was to use a lengthened and retuned Jeep Grand Cherokee (as the Dodge Nitro was a lengthened and retuned Jeep Liberty).

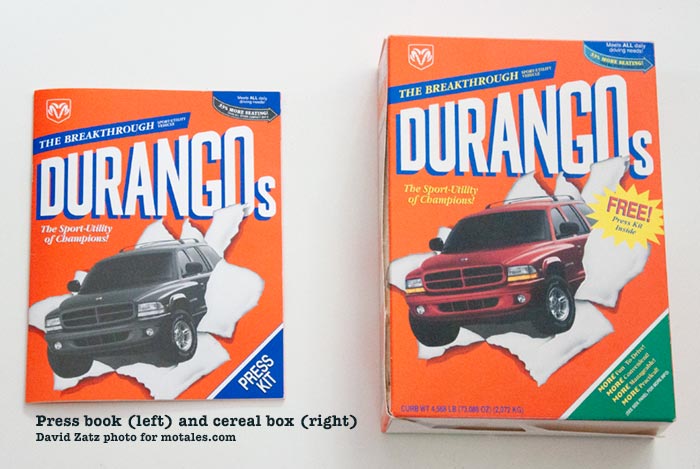

The development of the Durango was as innovative as the vehicle itself; and we cover that after running through the introduction and the year-by-year changes. We then conclude with some impressions of each generation.

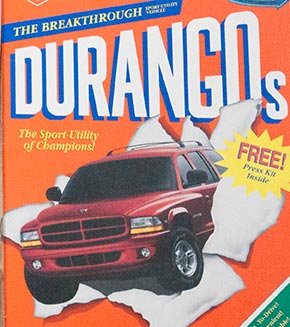

Needing to compete in the ever-growing truck-based-SUV segment, Dodge released the 1998 Durango in 1997. Based on the Dakota’s platform, it was technically a midsize SUV, but sometimes Dodge referred to it as compact.

The body-on-frame Durango could hold three rows of passengers (as an option)—seven people—and tow up to 7,500 pounds. It had the same front end and interior layout as the Dakota.

The Durango had two engines for 1998; both were V8s, dating back decades but upgraded numerous times for dramatic power, economy, and drivability boosts. The 5.2 liter V8 (318 cid) produced 230 horsepower and 300 lb-ft of torque, while the 5.9 liter (360 cid) produced 245 horsepower and 335 lb-ft of torque. There was only one choice of transmission, a four-speed automatic which was descended from the old Torqueflite 727 three-speed, but with an overdrive unit and electronic controls.

All the 1998 Durangos had four wheel drive, and were sold in just two trims: SLT and SLT Plus—but there were two types of four wheel drive: part-time and full-time. The part-time system was better for offroad use, but on dry roads, it scrubbed the tires and made tight turns impossible, because it mechanically locked all four wheels to each other.

Industry firsts included hydroformed frame crossmembers, a second-seat fold-and-tumble mechanism, and an S-shaped rear spring main leaf. The Durango also had the largest bodyside aperture panel ever used by Chrysler to this time. Within its class, it was the only SUV with standard aluminum wheels, a standard functional roof rack, and a forward-facing third row of seats.

Ride and handling were a key, and both surpassed most buyers’ expectations. Part of that was because of the fully boxed frame, three times stiffer than the Dakota 4x4’s—despite the money that would be saved by sharing frames. The frame weighed only slightly more than the Dakota’s (with the same wheelbase), due to computer modeling and new thickness optimization software. Splaying the frame outboard in back provided more interior space, as well as space for a 25 gallon tank, spare tire, and low restriction exhaust. Dennis Moothart, head of truck chassis engineering, wrote, “Our target was the Dakota feel in an SUV frame, which meant keeping the weight gain to a minimum.”

The Durango came with variable ratio steering and a quicker overall gear than Dakota, to make it feel more nimble; the ride height was dropped by an inch to aid handling and entry/exit. Brakes were enlarged from the Dakota, partly to increase towing capacity.

The second row had a 40-20-40 bench seat for cargo flexibility; it could form a flat load floor when folded forward, as could the third row, providing van-like space for 88 cubic feet of cargo. The optional rearmost seat was a full bench, placed over the rear axle to take advantage of the natural foot well. Storage behind the rear seat included a hidden storage compartment behind the axle, providing both a flat loading floor, and a hiding space for the spare, jack, and other tools.

As the model-year went on, next-generation airbags, which exploded with less force, were phased in.

The 1999 Durangos were no longer V8 and 4x4 only, with rear drive and the 3.9L Magnum V6 becoming standard. The V6 had been created for the original Dodge Dakota by modifying a V8, and was not especially smooth or efficient. Steering wheel-mounted audio controls and heated exterior mirrors became available and leather seats and body colored fender flares became standard on the SLT Plus. The steering gear on the 4x4 was upgraded to address earlier reliability issues.

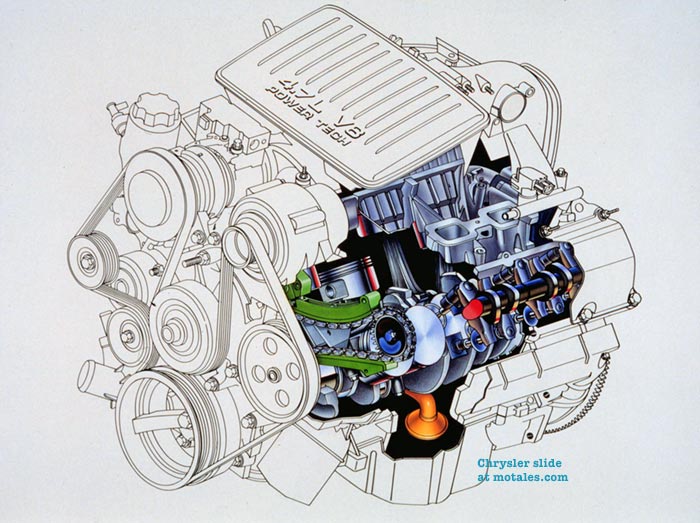

In the 2000 Durangos, the venerable 5.2L V8 engine was replaced by the brand new 4.7L Magnum V8, which had been developed with Jeeps and trucks in mind. The 4.7 (called “Next Generation” when used in Jeeps) was paired with a 45RFE automatic which had five forward gears; since one was only used in kickdown acceleration, it was officially a four-speed. Some missed the grunt of the old 5.2, but the smooth 4.7 was cheaper to make and easier on gasoline.

Trim levels were expanded to SXT, Sport, SLT, SLT Plus, and R/T for 2000.

The 2001 Durango had a redesigned interior, and the 4x4 transfer case control was moved to the dash courtesy of new, electronically shifted New Venture NV233HD and NV244 transfer cases. Dual zone climate control and six-speaker sound became standard on all models, and the seats were more comfortable. The V6 was not continued to 2001, given that the 4.7 provided better economy.

For 2002, Dodge upgraded the automatic transmission to the 545RFE—essentially the 45RFE, but with newer programming and an added overdrive ratio. Technically it had six forward gears, but one was only used for kickdown acceleration. With the added overdrive ratio, at 70 mph, the engine (with standard axle) would be going just 2,000 rpm, 10% lower than with the 45RFE; this increased fuel economy went up and reduced noise. The 545RFE replaced the 45RFE in January 2002 as a running change.

A new rear wheel antilock brake system included electronic brake apportioning, and curtain side airbags were added to the first two rows. Finally, a brake-shift interlock was added in.

2003 Dodge Durango buyers got standard four-wheel disc brakes, new cast aluminum wheels on the Sport, a four-gauge cluster on Sport and SXT, minor changes to the interior styling, and an optional six-disc in-dash CD player. Mandatory safety upgrades were LATCH child seat anchors, constant force retractors, and upper head impact protection for the first row.

David Zatz reviewed the 2002 Durango for Allpar; he liked the way the rear seat folded down to the floor, and the way the middle seats folded and tumbled out of the way with a good hefty tug on a convenient lever. He also noted the large rear air vents as being better than in most competitors. The five-speed automatic was responsive and performed well. The 4.7 was quiet except under heavy acceleration, when it made muscle-car noises. He saw ride and handling as being less satisfactory than in the Dakota Quad Cab (but still good), and slightly overinflated tires led to some feelings of instability on the highway .

The controls were well suited to the vehicle, and easy to use. The center console was handy, with padded storage areas, and a place for coins. Interior space was good and the rear seats were more accessible than in similar vehicles. The interior was cargo-friendly, with a nearly flat loading floor easy to get. Seats were comfortable.

The Durango might not have been made without SCORE and the extended enterprise.

Before the 1990s, Chrysler would probably have copied the equivalent Chevrolet or Ford, and asked for customer input after prototypes had been completed and most everything had been baked in. For the new Durango, they studied not just SUV owners, but also minivan and car and truck owners. They discovered that people wanted higher performance, more comfort and interior space, better ride and handling, and higher towing capacity; so the team made its priorities interior space, ride, handling, and overall capability.

Many buyers didn’t want a full-sized SUV, but often needed three rows of seats; they wanted to be able to fold their seats down to make way for cargo when needed. They also wanted the power and towing of a full size pickup, with the ride and handling of a car. The team matched these opposing desires by carefully positioning the body-to-frame mounts, which were lined up with body pillars and next to the third row of seats. Only some of these were used on the Dakota.

The Dodge Durango went from concept to production in 132 weeks, setting a corporate record; key to the speed was simultaneous design and engineering, and eliminating department-to-department handoffs by having people work together in a cross-functional team incorporating Advance, Body, Interior and Chassis Engineering design—all in the same location.

Designers started with sketches, then switched to CATIA to design the panels and the Chrysler Data Visualizer (CDV) to create renderings. Design engineers, stamping engineers, and suppliers worked with the designers. Fit, finish, and interference issues could be seen from any angle on CATIA screens; clay and fiberglass models were made only after the design was approved, a Chrysler first.

Because changes were easy to visualize, designers experimented with surface aesthetics rather than sticking to the clay model. Using CATIA and CDV, the exterior surface was designed in three weeks, and the interior was completed in half the normal time.

Each change was quickly scrutinized by everyone affected. One major focus was fitting in three rows of seats without changing the frame or exterior; CDV allowed any panel to be made transparent, helping with outward visibility studies (whether the view of the outside was blocked by pillars, third brake lights, and such). Panel attachments and space usage issues were easily resolved because the surfaces could be moved electronically.

Before benchmark studies began, a simplified, hybrid finite element model (FEM) was ready; within three months of the program’s start, four prototype vehicles, using tubular structures based on the hybrid FEM for bodies, were doing initial ride and handling evaluations. Quick-tooling technology and preliminary surface data facilitated the creation of early design-intent vehicles for testing and development.

Engineers did interior and exterior development at once. Advance Engineering built a full-size seating buck as soon as design data was available; it was made using computer data, and included all interior surfaces and window openings (for visibility checks). Accurate doors and a lift gate were formed from carbon fiber sheets based on the CATIA data. Seats were built by the supplier, so they could check seating, entry and exit room, and head clearances. A jury of employees made subjective evaluations of comfort.

Bob Holdreith, Executive Engineer for Advanced Truck Engineering, said they had thought about doing rear-facing rear seats to make it easier to fit eight people. “That was a compromise and we weren't happy. We felt that was like making an eight-passenger SUV just for the sake of it ... anyone who has carried children in a rear-facing third seat knows that the ‘car-sickness’ factor goes up exponentially.”

They started looking for space, but the instrument panel and front seats were taken from the Dakota and could not be changed. The rear doors could be enlarged by making the front doors smaller; that made it easier to get into the middle and back rows. They raised the roof around two inches from the back of the second seat; this allowed for raising the rear rows, making “theater style” seating and creating more legroom. The rear air conditioner was placed in front of the raised area to provide direct airflow without using precious headroom. The roof rack was placed directly over this area to create a natural visual flow from the front of the roof to the rear and hide the raised roof.

A multiplex data network (electronics bus) provided many electronic features with just two wires; to prevent conflicts, only one unit could transmit data at any time, and each unit had different priorities assigned to it. The components in the network were the:

The speedometer was really a voltmeter with mph or kph markings; its signal came from the computer, fed by an antilock brake sensor, which eliminated a separate speed sensor in the transmission, and was done in other 1998 Dodge trucks, too.

Redline for the LA series engines was 5,250 rpm; for the 4.7 liter, it was 6,000 rpm. Gas mileage is with rear wheel drive where possible. The 4.7 was downrated by 5 hp for California.

| Horsepower | Torque | MPG | |

|---|---|---|---|

| 3.9 (1998) | 171 @ 4800 | 225 @ 3200 | 15/18 |

| 4.7 (2002) | 235 @ 4800 | 295 @ 4800 | 15/20 |

| 5.2 (1998) | 230 @ 4400 | 300 @ 3200 | 13/17 |

| 5.9 (1998) | 245 @ 4000 | 335 @ 3200 | 12/17 |

| Bore | Stroke | Compression | cid | |

|---|---|---|---|---|

| 3.9 | 3.91 | 3.31 | 9.1 | 239 |

| 4.7 | 3.66 | 3.41 | 9.3:1 | 287 |

| 5.2 | 3.91 | 3.31 | 9.1 | 318 |

| 5.9 | 4.00 | 3.58 | 8.9:1 | 360 |

The transfer cases all had a 2.72:1 low gear; the NV242 had a 48/52 front/rear torque split and a planetary center differential with locking in low and high gears.

| Gear | V6 | V8 |

|---|---|---|

| Axle ratio | 3.55 | 3.92 |

| Part time transfer case | NV231 | NV231HD |

| Full time transfer case | NV242 | NV242 |

| Transmission | 42RE | Various |

| Curb weight | 4,568 | 4,689* |

* 4,736 with 5.9 engine. Figures are from 1999. Curb weight includes the driver and all fluids.

The V8 models used the 44RE transmission with the 5.2 engine, and the 46RE for the 5.9. Later models used the 45RFE and 545RFE, which were essentially similar. All had hydraulic control with an electronically governed governor, overdrive lockout, and converter clutch.

| Gear | 46RE | 42RE+ 44RE |

|---|---|---|

| 1st | 2.45 | 2.47 |

| 2nd | 1.45 | 1.54 |

| 3rd | 1.00 | 1.00 |

| 4th | 0.69 | 0.69 |

Durangos in this generation had a 6,400 pound gross vehicle weight.

Electrical: 117 or 136 amp alternators. Dimensions:

| Wheelbase | 115.9 (2,944) |

|---|---|

| Length x Width | 193.3 x 71.5 |

| Floor Height | 31.8 |

| Breakover Angle | 19.5° |

| Departure Angle | 26.3° |

| Approach Angle | 28.4° |

| Cargo volume | 18.8 cu ft All seats folded: 88.0 |

| Headroom | 39.8 / 40.6 / 37.9 (by row) |

| Legroom | 41.9 / 35.4 /30.7 (by row) |

The basic design had a longitudinal front engine; its ladder-type frame had 12 rubber isolators from the body. The front suspension used upper and lower A-arms, torsion bars, gas-charged shocks, and a stabilizer bar while the rear suspension had a live axle with four-leaf springs, a stabilizer bar, and gas-charged shocks. Brakes were vented discs in front, drums in back.

The Durango might not have been made without SCORE and the extended enterprise.

See the next generation 2004-2009 Dodge Durango

Italy slaps Elkanns’ wrists in tax case

See how Jeep, Dodge, Ram, Chrysler do on new quality-vs-cost chart

Copyright © 2021-2025 Zatz LLC • Chrysler / Mopar car stories and history.

YouTube • Editorial Guidelines • Videos

Tailfins Archive • MoTales on BlueSky